FORM QTC3-EG6 (1118)

QUANTECH 5

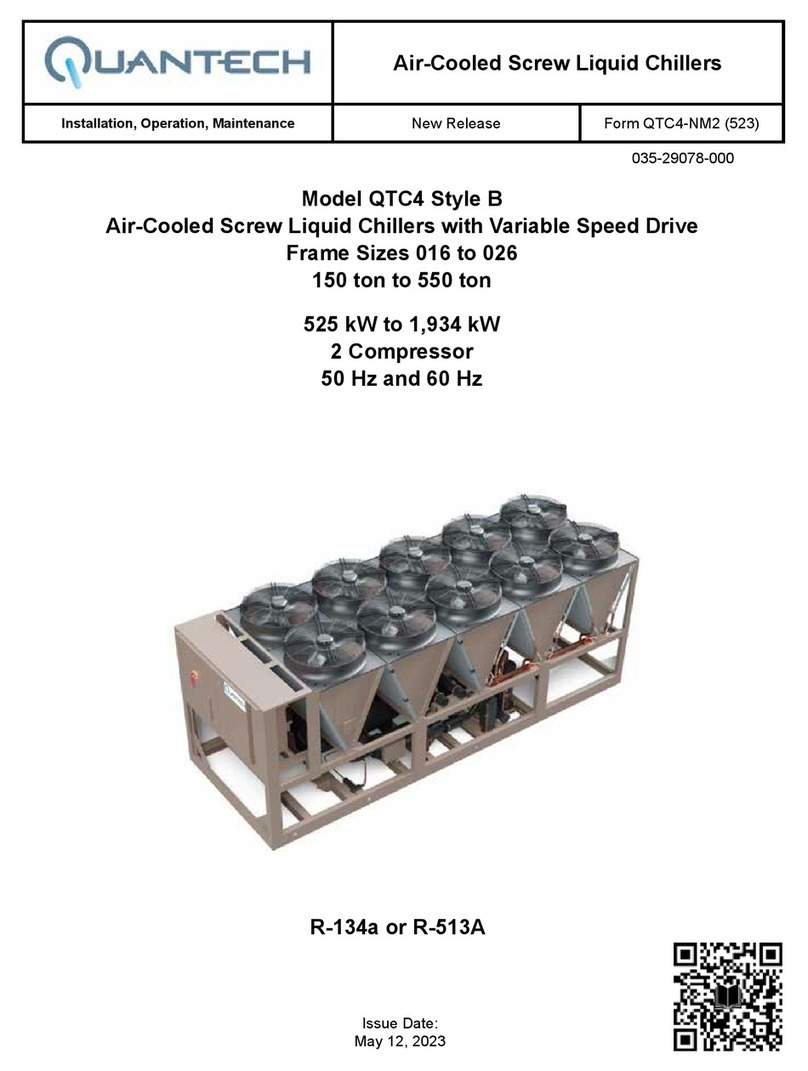

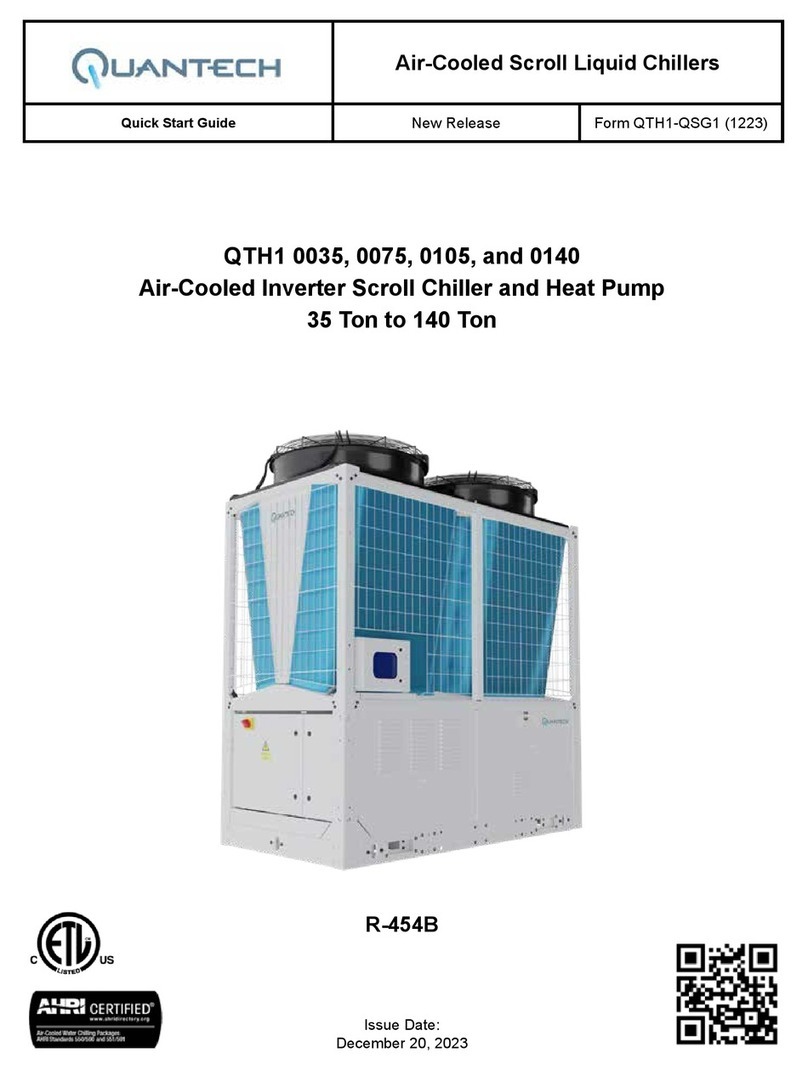

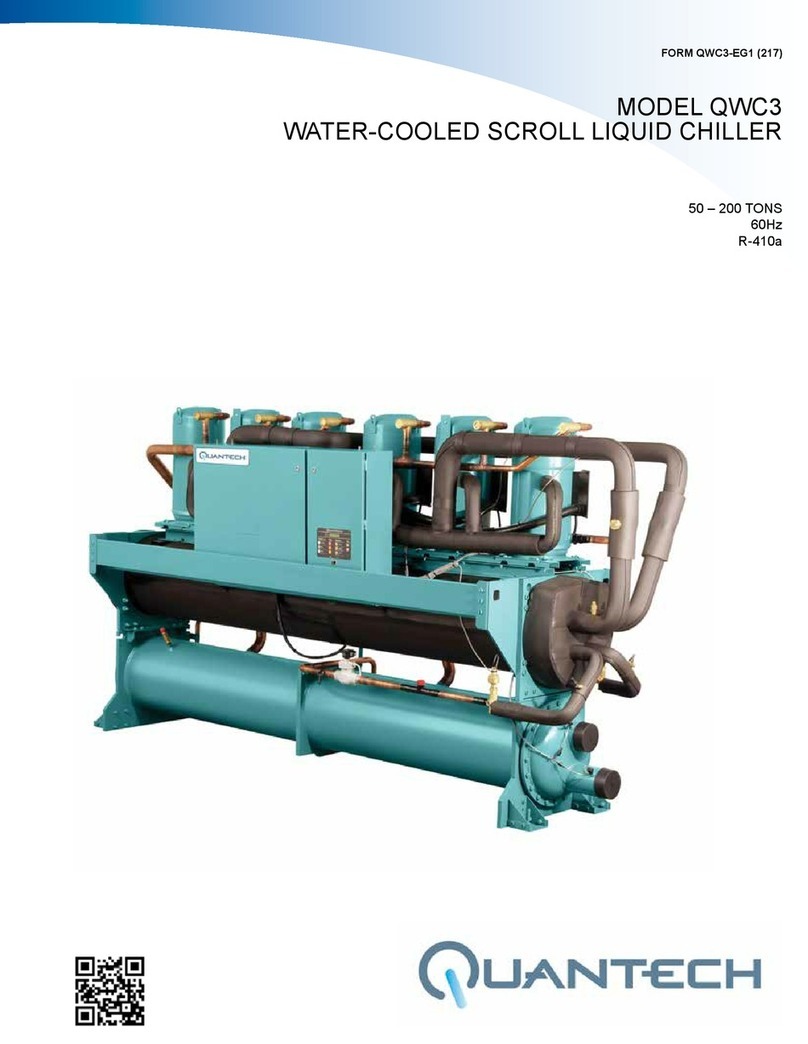

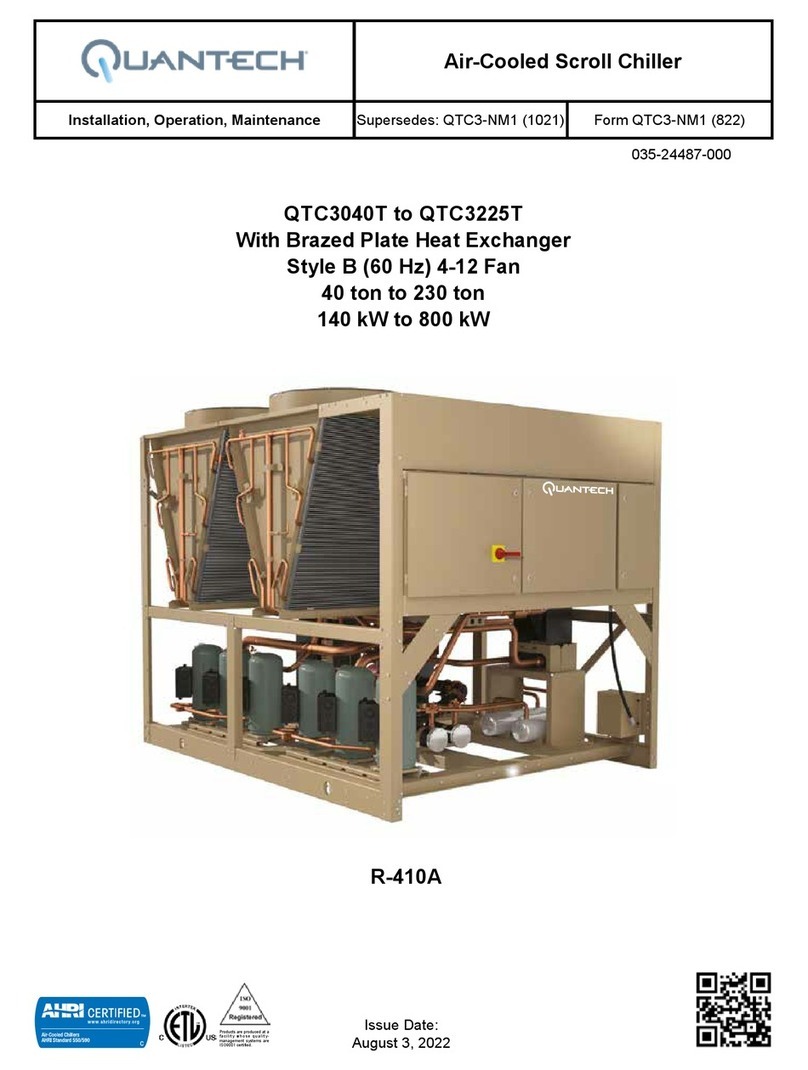

Quantech™ is proud to present the Model QTC3 Air-Cooled Scroll Chiller.

FEATURES AND BENEFITS

Installation

The QTC3 chiller arrives as a factory-assembled package ready to be installed outdoors,

either on the roof or at ground level. The air-cooled condensers eliminate the capital,

installation and maintenance costs of a cooling-tower circuit.

The QTC3 weighs less and has s smaller footprint than other chillers in its class. In fact, it

is 20-35% lighter weight than the market average chiller. When the chiller is roof-mounted

in new construction, the cost of the support structure can be reduced. In building retrofits,

the QTC3 can provide the largest capacity in a given space and existing structure.

Power hook-up could not be any easier with the standard single-point connection. A ter-

minal block, disconnect switch or circuit breaker is provided to meet the unique needs of

every project and minimize installation time and labor. The factory-installed control trans-

former steps down the power voltage to the control voltage.

Chilled-water piping is also simple. The water connections are factory-piped to the out-

side of the unit, for ease of access. Factory-cut grooves, or optional flanges, make pip-

ing connections simple. Optional factory-installed pump kits eliminate the time, cost, and

mechanical-equipment room space necessary to install chilled-water pumps.

Press the start button with confidence – your QTC3 has been run-tested at the factory to

ensure that you will have a successful start-up.

Reliability

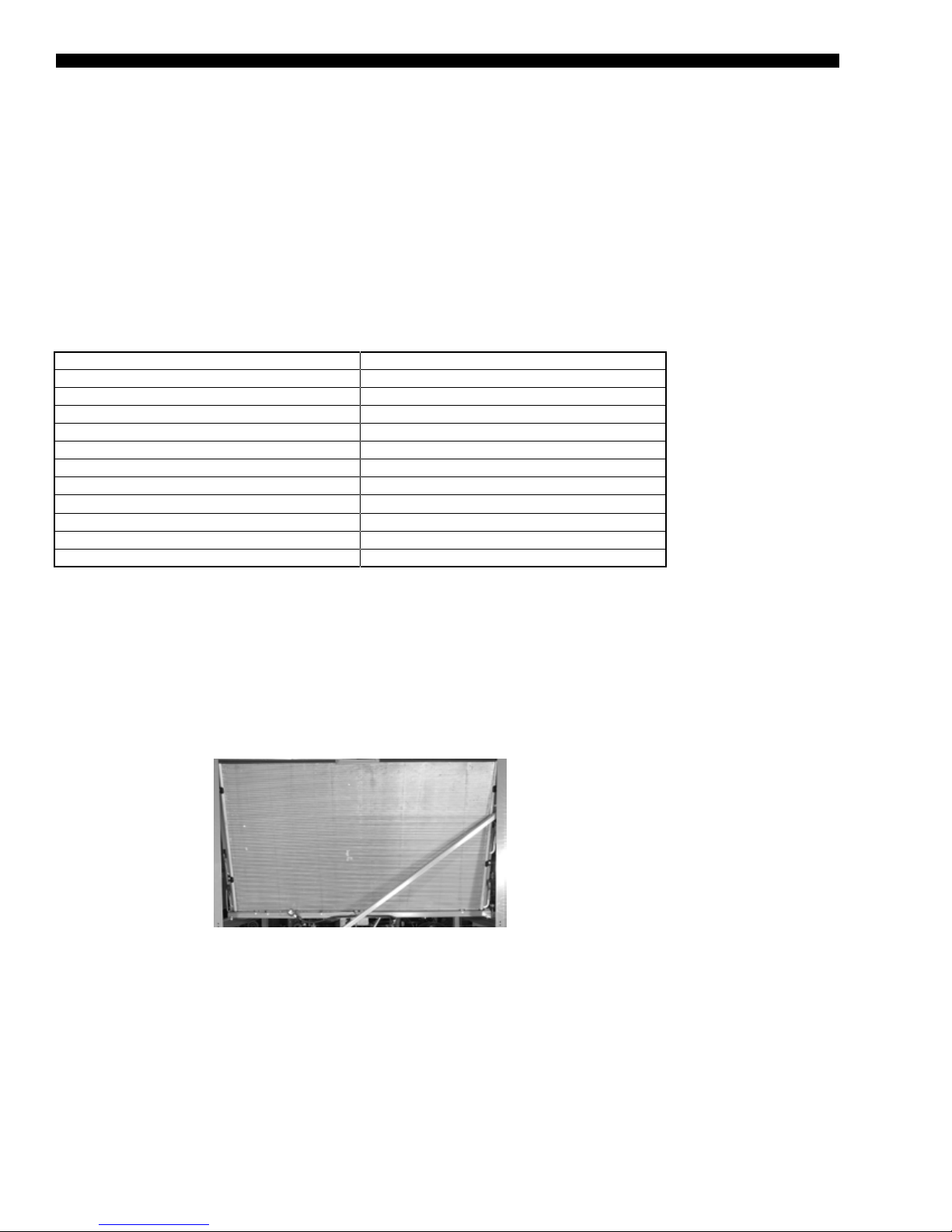

The QTC3 chiller is proven and reliable, designed to reduce service calls. The scroll com-

pressors have logged hundreds of thousands of operating hours in numerous different

applications. The corrosive-resistant condenser heat exchangers have been specifically

designed for stationary HVAC applications and have undergone extensive laboratory and

field testing to extend chiller life and improve performance. They are also more rigid than

standard condenser coils, making them less susceptible to damage during rigging, lifting,

and installation of the chiller.

Components are designed to keep the chiller up-and-running. A factory-installed water

strainer prevents debris from affecting unit flow and/or heat transfer. The rugged thermal-

dispersion flow switch is factory-installed at the optimum location in the piping for superior

flow sensing, reducing the potential for nuisance trips. Intelligent controls protect the

chiller while keeping it online, for maximum uptime. Exterior panels of the chiller are

powder-coated with highly durable corrosion-resistant paint.

Introduction