FORM QWC3-NM1

ISSUE DATE:11/20/2020

QUANTECH 5

TABLE OF CONTENTS

SECTION 1 – GENERAL CHILLER INFORMATION AND SAFETY ................................................................ 11

Introduction..................................................................................................................................................... 11

Warranty ......................................................................................................................................................... 11

Safety ............................................................................................................................................................. 11

Misuse Of Equipment .....................................................................................................................................12

SECTION 2 – PRODUCT DESCRIPTION...........................................................................................................13

Introduction..................................................................................................................................................... 13

Compressors ..................................................................................................................................................13

Refrigerant Circuits......................................................................................................................................... 13

Evaporator......................................................................................................................................................14

Condenser......................................................................................................................................................14

Refrigerant Circuit ..........................................................................................................................................14

Microprocessor Control Center ...................................................................................................................... 14

Power Panel ..................................................................................................................................................15

Accessories And Options ...............................................................................................................................16

Control / Power Panel Components ...............................................................................................................18

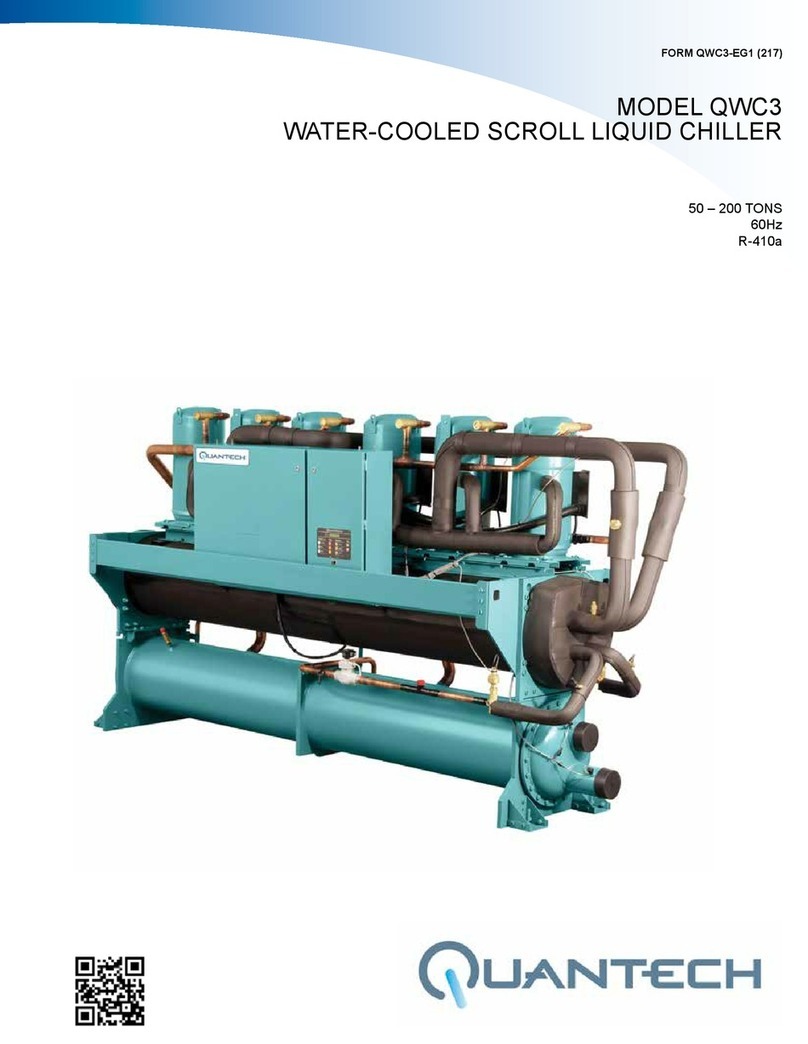

Unit Components............................................................................................................................................ 20

Product Identification Number (Pin) ...............................................................................................................22

Refrigerant Flow ............................................................................................................................................26

SECTION 3 – TRANSPORTATION, HANDLING AND STORAGE ...................................................................29

Delivery And Storage......................................................................................................................................29

Inspection .......................................................................................................................................................29

Moving The Unit .............................................................................................................................................29

Lifting Weights................................................................................................................................................30

SECTION 4 – INSTALLATION .............................................................................................................................31

Installation Checklist....................................................................................................................................... 31

Location Requirements ..................................................................................................................................31

Unit Isolation (Noise Sensitive Location)........................................................................................................31

Foundation .....................................................................................................................................................31

Installation Of Vibration Isolators ...................................................................................................................32

Pipework Connection .....................................................................................................................................32

Water Treatment.............................................................................................................................................34

Option Flanges ...............................................................................................................................................34

Refrigerant Relief Valve Piping.......................................................................................................................34

Condenser Cooling Liquid Systems ...............................................................................................................35

Pressure Tapping............................................................................................................................................36

Pipework Arrangement ...................................................................................................................................36

Connection Types And Sizes..........................................................................................................................36

Electrical Connection...................................................................................................................................... 37

Field Wiring ....................................................................................................................................................37

Control Panel Wiring ...................................................................................................................................... 37

Power Wiring ..................................................................................................................................................38

Compressor Heaters ......................................................................................................................................39

Relief Valves...................................................................................................................................................39

High Pressure Cutout .....................................................................................................................................39

Control Wiring................................................................................................................................................. 40