*A quick note on EMP

An EMP, or Electro-Magnetic Pulse is a devastating phenomenon that, while harmless to living

things, absolutely destroys anything electronic. t consists of extremely powerful electromagnetic fields

building and collapsing hundreds of thousands of times per second. This induces potentially huge

electric currents in anything that conducts electricity, causing components connected to said conductor

to burn out. An EMP can be caused by either a deliberate, high-altitude nuclear warhead detonation,

or can be caused naturally by a solar event called a Coronal Mass Ejection, or CME.

All Quantum Harvest power units are built into a specially designed enclosure, more

properly called a Faraday Cage, named after Michael Faraday, an early pioneer in

electromagnetic research. The purpose of a Faraday cage is to intercept and divert

electromagnetic energy away from the box's interior, thus protecting the contents.

The principles involved are fairly simple, but the proper execution is critical. n order

for the enclosure to be useful, it must have a door, but any opening larger than a square

centimeter or so allows too much energy to penetrate the interior, thus defeating the purpose of

the Faraday cage.

The solution to this conundrum is to gasket the door with a special type of conductive

gasket, mated to a copper or silver strip that is electrically bonded to the main box. The key is

to have very low electrical resistance between the door and the enclosure, with no gaps. This is

not as easy as it sounds, and requires special materials designed specifically for this

application.

My experience with Faraday apparatus comes from 8 years experience with very

powerful industrial machines called RF welders. These machines use extremely powerful and

focused bursts of electromagnetic energy to weld and form plastic parts. These machines

basically create a local EMP every time they fire, and it is critical that stray energy be confined

and dissipated safely to avoid damage to other sensitive electrical machinery.

==========================================================

Table of ontents

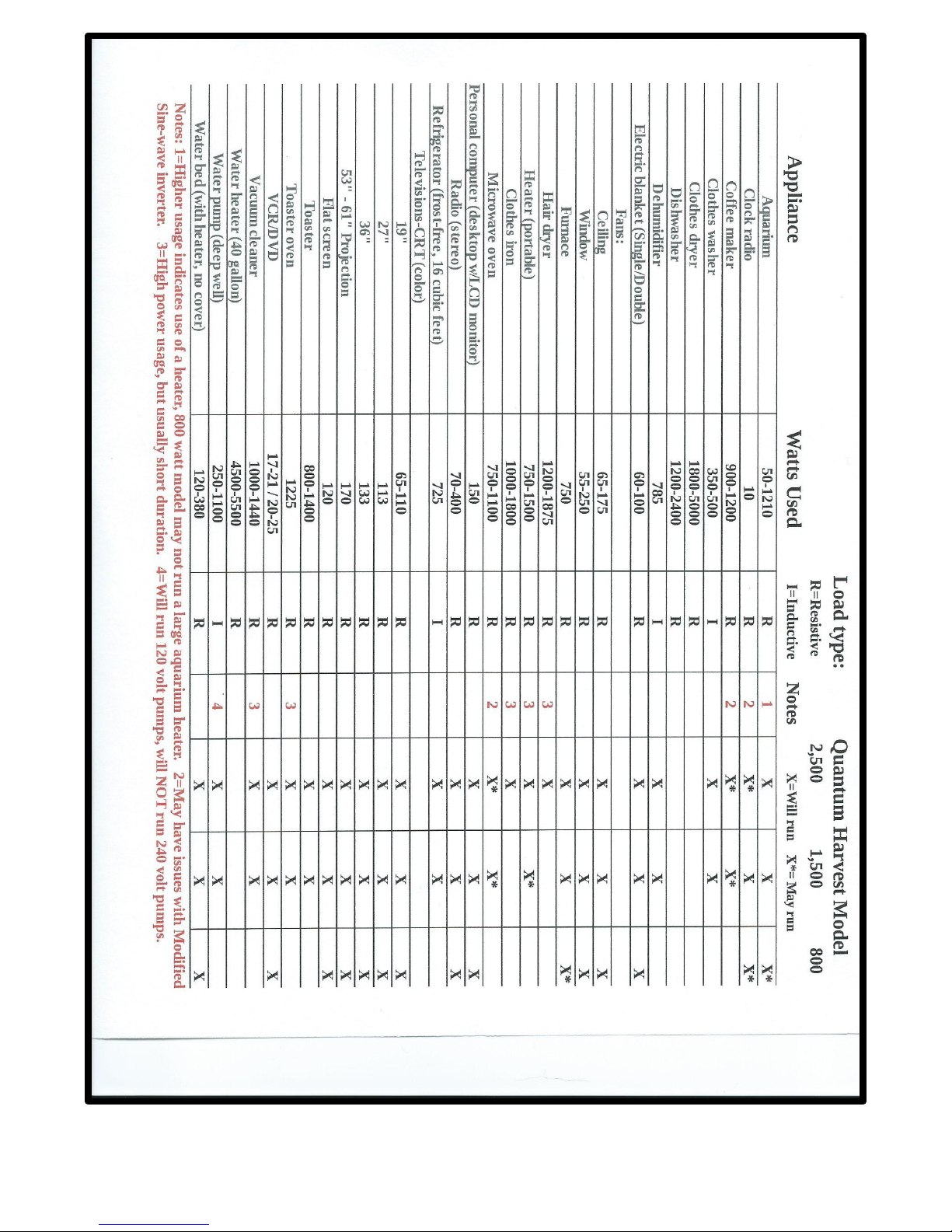

Specifications.......................................................................................Page 3

Note on Batteries.................................................................................Page 4

Section 1............ apacities and recommended usages.....................Page 5-6

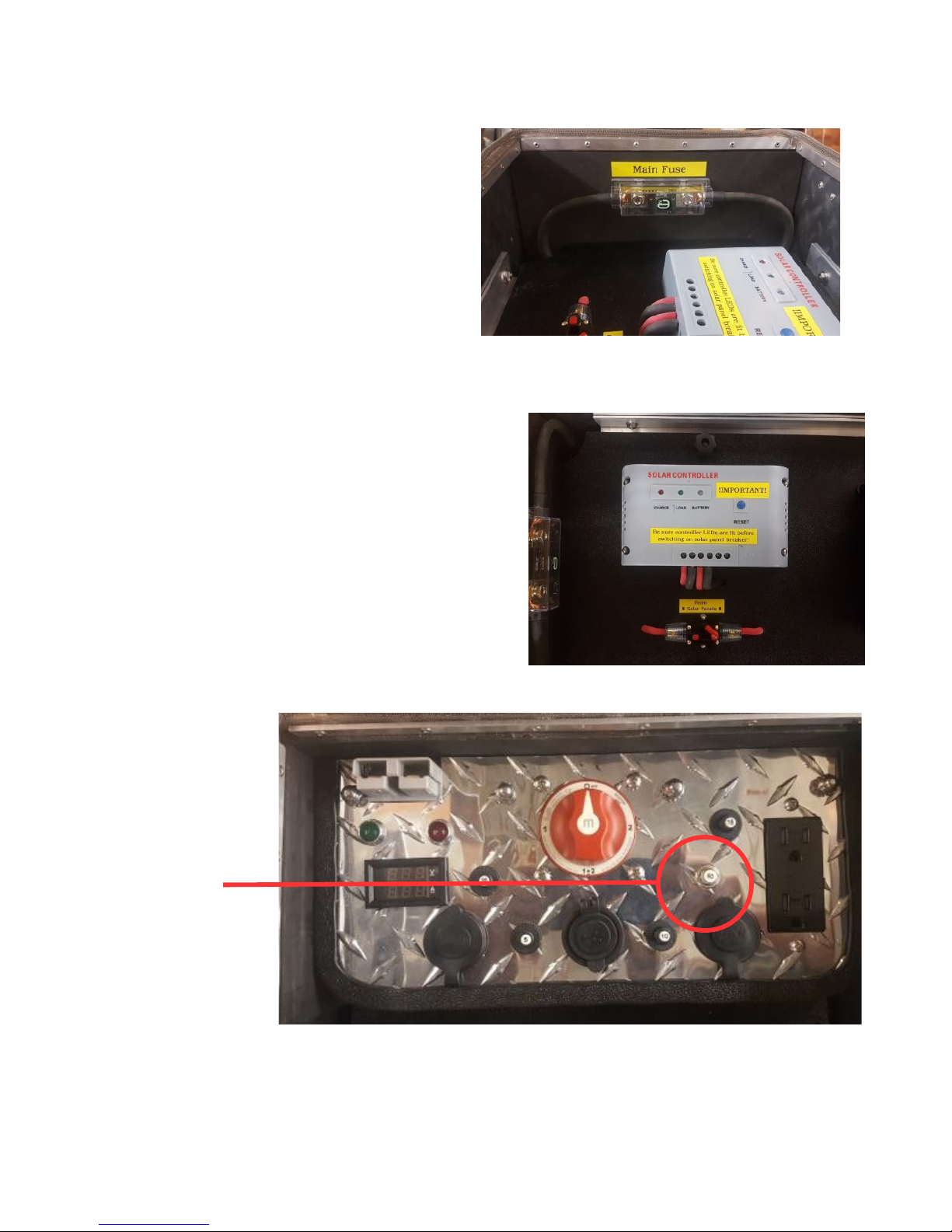

Section 2............ ontrols/ ircuit Protection Devices.......................Page 7-9

Section 3.............External Ports and onnectors..............................Page 10

Section 4............Operation and Routine Maintenance.....................Pages 11-13

Section 5.............Using Booster ables..............................................Pages 14-16

Section 6.............Maintenance and Repair........................................Pages 17-38

Section 6A.............Power Board...............................................Pages 17-19

Section 6B............ ontrol Panel...............................................Page 21

Section 6 .............Batteries......................................................Pages 22-38

ontact Information...........................................................................Page 39

Warranty Information........................................................................Page 40

Addendum A................Wiring Schematic.........................................Page 41

Addendum B.................Replacing solar panel diodes......................Page 42-43

2