Section 3: Setup Mode Page 7

PM9605 Revision 1, 9605 Version 36.1.1

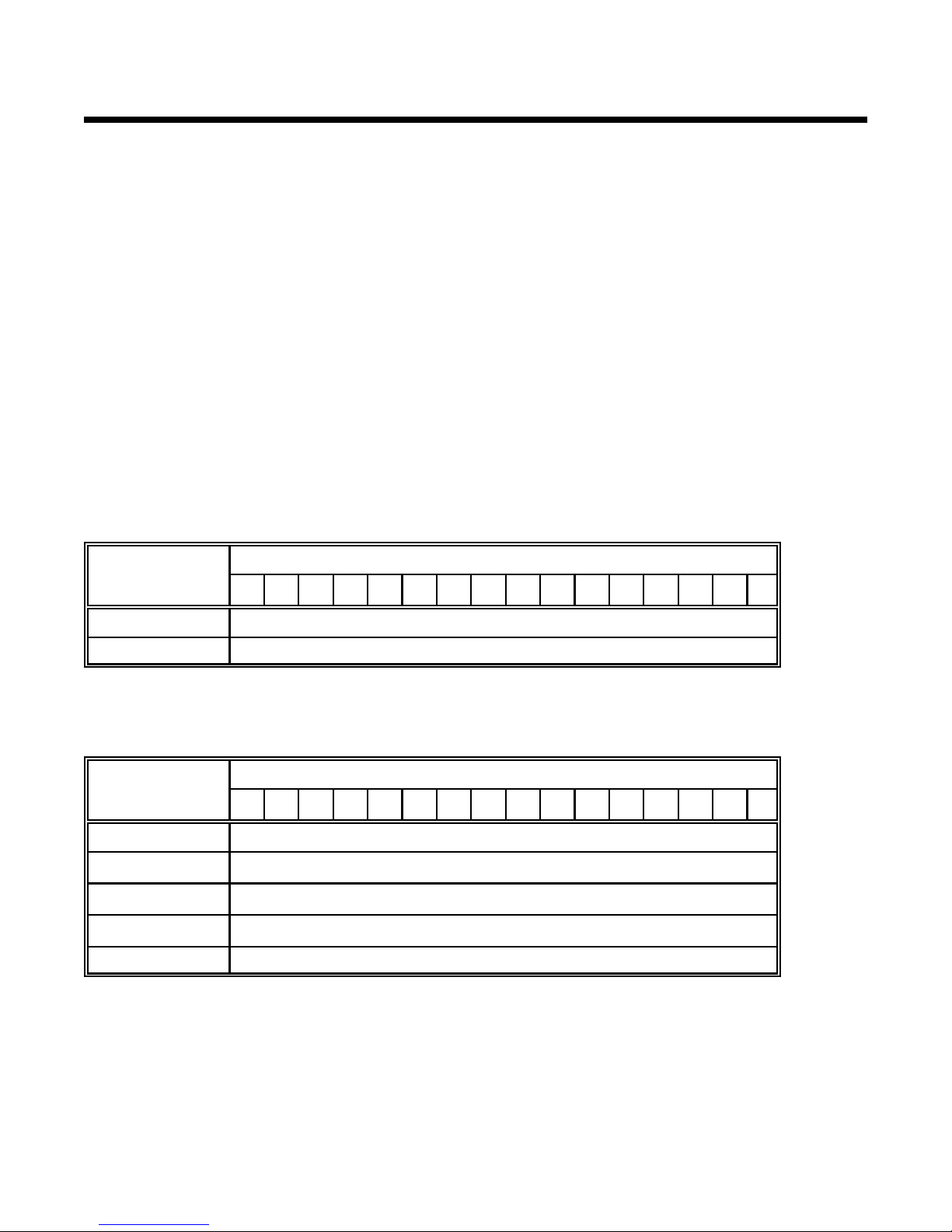

The last two rows of LEDs will be used to display the current value of the 9605 node address, SLC-500 (DH+)

node address, Watchdog file number, Watchdog element number, or Dialogue File number depending on which

parameter is selected. The value will be entered and displayed as a two digit BCD number (See figure 1).

Example

Perhaps the best way to describe the process of changing the Setup parameters is with an example: To set the

Dialogue File to B 24, the operator would:

<Position the slide switch to the on position. Then apply the power to the 9605, to enter Setup Mode. If

Setup mode is entered properly the 9605 will cycle every LED green followed by the indicators turning off

with the exception of the Operating Mode LED.

<After power up, press the [5] key (see page 7 for key assignments). Notice how the number 5 led turns

Amber and the last two rows of LEDs change; The last two rows of LEDs display the current value of the

parameter. The value is a two digit BCD number. (See page 10 for a review of BCD numbers.)

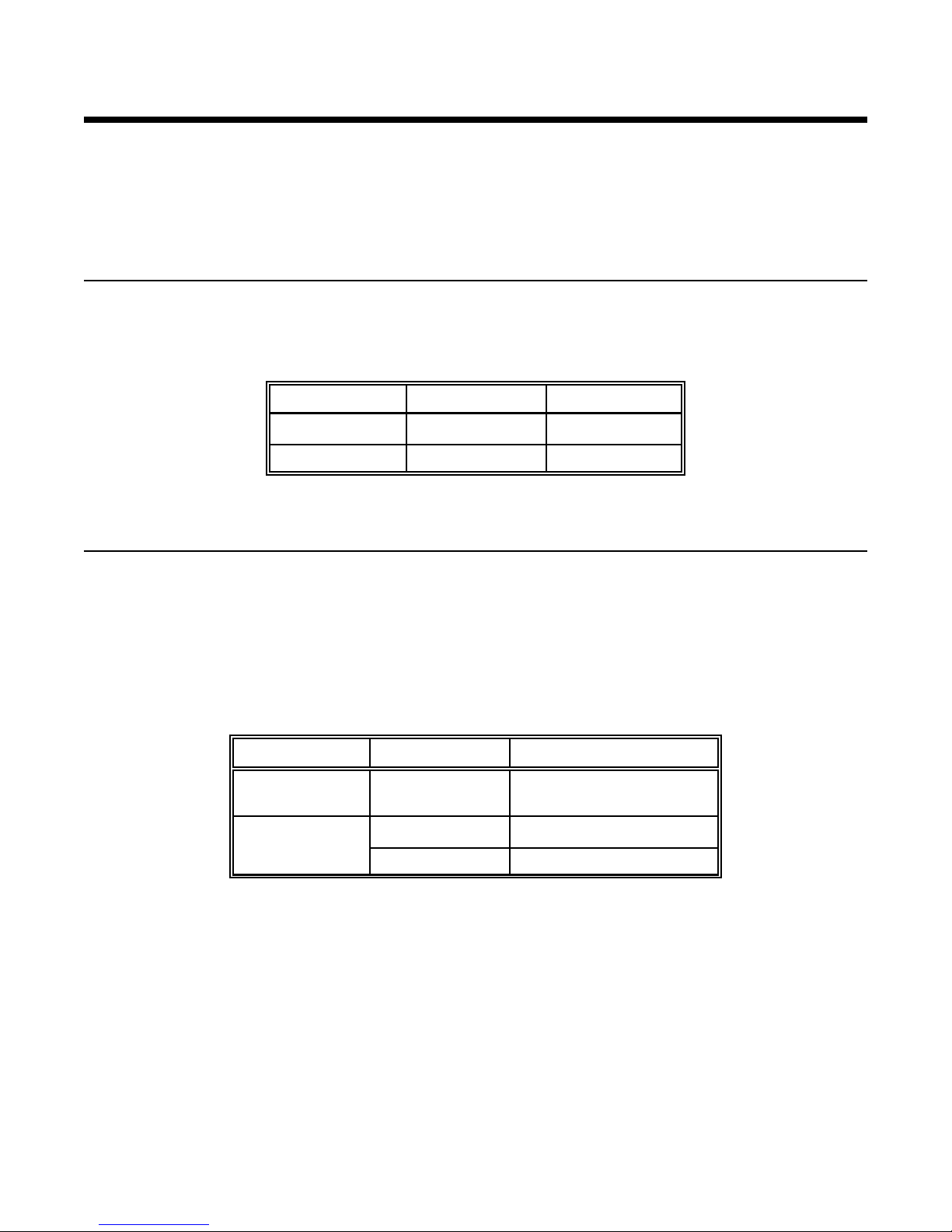

<When LED 5 is amber, the Dialogue File number will be displayed in BCD. If you want to change this,

simply use the last two rows of keys to toggle the bits of the BCD number. A green LED means the bit is

zero (0); a red LED means the bit is one (1). You may press as many keys as needed to make up the

desired number. For the example, to make the Dialogue File 24, LEDs 11 and 14 need to be switched

Red the rest of the LEDs should be green. Once this LED pattern is set press the [5] key again to enter

this new value into memory. Note: If you don't press the [5] key a second time the changes will not be

saved.

<If your entry is accepted, the LEDs will turn off with the exception of the Operating Mode LED. If there is a

problem with your entry, the last two rows will flash amber and the 9605 will reject the new value. It will

return you to the parameter where you can adjust it to an acceptable value.

<Repeat the steps mentioned above to change any or all of the remaining setup parameters to match the

application needs. Keep in mind that SLC-500 uses the OCTAL numbering system for node addresses.

In that system any number with 8 or 9 is invalid, therefore keys 9 and 13 (normally used as BCD 8 for

other Setup parameters) will be disabled on the 9605 to prevent an illegal station address from being

entered.

<When the setup of the 9605 is complete, it is a good idea to view all of the setup parameters a second

time to insure that the proper values were entered in properly.

<When satisfied with the setup of the 9605, the slide switch must be placed in the off position. Once the

proper communication cable is attached, the 9605 can attempt to establish communications with the

processor by either pressing the [7] key (RESTART) or by cycling power to the 9605.