Quattro QUATTRO600 User manual

1

REMOTE CARAVAN MOVER

Framework and Motor Installation Guide

EN

QUATTRO600 - Diamond

QUATTRO500 - Rhodium

EGO500 - Platinum

WOHNWAGEN-FERNVERSCHIEBER

Rahmen und Motorinstallationsanleitung

DE

CARAVAN MOVER OP AFSTAND

Handleiding voor de installatie

van frame en motor

NL

DÉPLACEUR DE CARAVANE À DISTANCE

Guide d’installation du cadre et du moteur

FR

MOTOR REMOTO PARA CARAVANAS

Guía de instalación de la

estructura y el motor

ES

FJERNBETJENT CAMPINGVOGN MOVER

Vejledning til installation af ramme og motor

DK

ZDALNE PRZEMIESZCZANIE

PRZYCZEPY KEMPINGOWEJ

Instrukcja montażu ramy i silnika

PL

02

Document Control

i

FR

ES

EN

DE

NL

Please visit www.purpleline.co.uk/caravan-movers before installation to check for any

updates on product specications, usage, safety or installation instructions.

Bitte besuchen Sie www.purpleline.co.uk/caravan-movers VOR Installation

auf Aktualisierungen zu Produktspezikationen, Nutzung, Sicherheit und

Einbauvorschriften zu überprüfen.

Kunt u terecht op www.purpleline.co.uk/caravan-movers vóór de installatie te

controleren of er updates over productspecicaties, het gebruik, de veiligheid of de

installatie-instructies.

Se il vous plaît visitez www.purpleline.co.uk/caravan-movers avant l’installation pour

vérier les mises à jour sur les spécications des produits, l’utilisation, la sécurité ou

les instructions d’installation.

Por favor, visite www.purpleline.co.uk/caravan-movers ANTES de la instalación para

comprobar si hay actualizaciones sobre especicaciones de productos, el uso, la

seguridad o las instrucciones de instalación.

Besøg venligst www.purpleline.co.uk/caravan-movers før installation for at

tjekke eventuelle opdateringer af produktspecikationer, brug, sikkerhed eller

installationsvejledninger.

Przed instalacją należy odwiedzić stronę www.purpleline.co.uk/caravan-movers,

aby sprawdzić wszelkie aktualizacje dotyczące specykacji produktu, użytkowania,

bezpieczeństwa lub instrukcji instalacji.

Original Instructions

Manual Reference: QTR-M006

REVISION DESCRIPTION ISSUE DATE

-

Original instructions

- Manual Reference: UM 1.3

- PDF: QUATTRO500_600_EGO500_UM_1.3.pdf

16/03/2021

01 - Visual amendments

- Manual Reference updated: QTR-M006 17/05/2021

02 Optional protective case references added. 17/03/2022

03 Ammendments to shark clamp visuals and tment

instructions. Compliance doccumentation update. 09/12/2022

04 Translations from original English 05/01/2023

DK

PL

03 EN

Table of Contents

CONTENTS PAGE NO.

Document Control 02

Table of Contents 03

Motor Mover Assembly Instructions 04 - 06

Package Contents (Fig.A) 07 - 08

Technical Reference Diagrams 09 - 13

Introduction 14

Fitting Guidelines 14

Specications 14

Installation - Safety Guidelines 15

Installation - Mechanical Components 16

Installation - Classic Clamp System 16 - 17

Installation - Shark Clamp System 17

Installation - Electrical/Electronic Components 17

Operation and Maintenance 18

Product Registration 19

Guarantee 19

Optional Fitting Adaptors 20

Approval Information 21

Contact Information 21

EU Declaration of Conformity 22 - 23

UKCA Declaration of Conformity 24 - 25

EN

04 EN

QUATTRO DIAMOND AUTO - Motor Assembly Instructions (1 of 1)

NOTE: Depending on the space available around where the motor movers will be tted, you may nd it easier to

t the framework to the chassis before assembling the motor movers onto the framework. To do this, loosely t the

framework as per the assembly instructions and t motors before nal spacing and torquing of the bolts.

B

D

E

Lower gearbox onto framework and align the front

and rear gearbox mounting holes with the

framework engagement slots as shown.

Pass pins (B) through both the framework slots

and gearbox mounting holes.

Fit washers (E) on pins (B), and press circlips (D) into

the grooves to secure in place.

Align rear framework hole with engagement motor

mounting hole by moving the gearbox rearwards in

the slots. Fit bolts (A) and torque to 5Nm.

Note: Instructions show nearside framework, offside

framework will be a mirror of this. Before beginning

installation remove upper packaging bolt (M) and

discard.

Quattro600

Auto Mover

Assembly

Revision 2

12

345

B

B

E

D

B

E

D

B

A

A

A

05 EN

A

B

C

D

E

A

Fit engagement arm (A) onto engagement teardrop

piece.

Lower motor onto framework and align rear

gearbox mounting hole with rear framework

slot.

Partially pass pin (B) through slot and gearbox

mounting hole.

Align pin with hole in engagement arm (A) and

partially pass pin (B) through, leaving space for the

spacer (C).

AB

Note: Instructions show nearside framework, offside

framework will be a mirror of this. Before beginning

installation remove upper packaging bolt (M) and

discard.

Quattro500

Manual Mover

Assembly

Revision 2

12

345

QUATTRO RHODIUM MANUAL - Motor Assembly Instructions (1 of 2)

NOTE: Depending on the space available around where the motor movers will be tted, you may nd it easier to

t the framework to the chassis before assembling the motor movers onto the framework. To do this, loosely t the

framework as per the assembly instructions and t motors before nal spacing and torquing of the bolts.

06 EN

QUATTRO RHODIUM MANUAL - Motor Assembly Instructions (2 of 2)

NOTE: Depending on the space available around where the motor movers will be tted, you may nd it easier to

t the framework to the chassis before assembling the motor movers onto the framework. To do this, loosely t the

framework as per the assembly instructions and t motors before nal spacing and torquing of the bolts.

Hand turn engagement bar (F) anticlockwise to ensure pin

(B1) is forced to the rear of the slot. Hold the spring (G) in

one hand and pass pin (B2) through the framework hole

and hook the end of the spring over the end of pin (B).

Tilt gearbox back to release spring tension to

allow pin (B) to be passed the rest of the way

through the framework.

Fit washer (E) and then circlip (D) into the groove on

the pin (B).

Pass final pin (B) through front framework slot and

gearbox front mounting hole. Fit washer (E) and

circlip (D).

Hold engagement bar (F) securely to prevent

movement and tilt mover forward to gain easy

access to underside. Fit spacer (C) in the gap

between the gearbox and engagement arm (A)

and push pin (B) through the rest of the way.

C

B

Fit washer (E) and then circlip (D) into the

groove on the pin (B).

E

D

B

F

B

1

F

B

2

B

E

D

B

E

D

B

678

910 11

A

G

07 EN

Package Contents (Fig.A)

REF. QTY DESCRIPTION

1 1 Motor Unit (A)

2 1 Motor Unit (B)

3 1 Main Cross Bar

4 1 Actuation Centre Bar (Rhodium Only)

5 2 Actuation Insert Bars (Rhodium Only)

6 1 Engagement Tool (Rhodium Only)

7 2 Classic Stop Bolts & Nuts (2 pairs)*

8 2 Upper Classic Clamp Plate*

9 2 Classic U Plate*

10 2 Lower Classic Clamp Plate*

11 1Convoluted Cable Trunking

12 2 Positive (+) Red Motor Cable

13 2 Negative (-) Black Motor Cable

14 1 Positive (+) Red Battery Cable

15 1 Negative (-) Black Battery Cable

16 8 Classic Clamp Bolts - M10x55*

17 8 Classic Clamp Nyloc Nuts M10*

18 8 Classic Clamp Washers 10mmØ*

19 20 P-Clip Screws - M4x15

20 10 Cable Trunking P-Clips 19.2mm

21 10 Cable P-Clips 10.4mm

22 4 Motor Terminal Connector

23 2 Battery Terminal Connector

24 6 Cable Spade Connectors

25 8 Motorside Framework Bolts

26 3 Cable Polarity Markers (+,-)

27 4 Motor Unit Cable Ties 8x400

28 10 Cable Ties 2x70

29 1 Power Isolation Switch + Key + Fixings

30 2 Roller Distance 20mm Spacers

31 1 User Manual (not illustrated)

32 4 Diamond Engagement Bolts (not illustrated)

33 2 Shark Clamp Mounting System*

*Depending on model, either Classic Clamp or Shark Clamp will be supplied.

i

08 EN

Fig.A

3

3

3

3

4

4

4

4

2

2

2

2

+

+

+

+

1

1

1

1

-

-

-

-

1

2

3

4

5

68

9

10

11

12

13

14 15

16

17

18

33

19

20

21

22

23

24 25

26

27

28

30

7

Motor A

Motor B

29

QUATTRO RHODIUM ONLY

DIAMOND / PLATINUM

QUATTRO RHODIUM ONLY

09 EN

Fig.1

Fig.2

A

B

C

A

B

C

D

E

F

G

Fig.3

C

G

A

RHODIUM MANUAL

RHODIUM MANUAL

DIAMOND AUTO

D

F

B

PLATINUM AUTO

Technical Reference Diagrams

10 EN

Fig.7

Fig.8

20mm

Fig.4

A

Fig.6

20mm

Fig.5

RHODIUM MANUAL

DIAMOND AUTO

DIAMOND AUTO

20mm

PLATINUM AUTO

DIAMOND AUTO PLATINUM AUTO

RHODIUM MANUAL

RHODIUM MANUAL

Technical Reference Diagrams

11 EN

Fig.10.1

Fig.9

175mm

(min)

30mm to 45mm

155mm

(min)

85mm (min)

2.8mm to 3.5mm

1800mm to 2500mm (max)

Fig.12

Fig.11

L – Profile U – Profile

Caravan Floor

CONTROL

UNIT

BATTERY

Fig.13

L - Prole U - Prole

Motorside

PLATINUM

AUTO

Technical Reference Diagrams

Fig.10.2

12 EN

Fig.14

Motor

A

Motor

B

Overhead View

Motor

B

Motor

A

QUATTRO

MANUAL

QUATTRO

MANUAL

Technical Reference Diagrams

13 EN

Technical Reference Diagrams

Fig.15

14 EN

Introduction

Fitting Guidelines

Specication

Thank you for choosing this caravan mover. This product has been produced according to very high

standards and has undergone careful quality control procedures. Simply by using the remote control

you can move your caravan effortlessly into any position required within operating guidelines.

Before proceeding with installation and starting to use the mover, please read this manual very

carefully and be aware of all the safety instructions! The owner of the caravan will always be

responsible for correct use. Keep this manual inside your caravan for future reference.

This User Manual covers three models of Caravan Mover: Model No. QUATTRO500, Model No.

QUATTRO600 and Model No.EGO500; any installation or operational differences between the two

models are detailed where appropriate.

The caravan movers consist of two 12V motor-powered rollers, a 12V electronic control box and a

remote control. To function,

the motor-powered rollers must be engaged against the tyres of your caravan. The supplied cross

actuation device (QUATTRO500 ONLY) enables you to engage both rollers at the same time from one

side of your caravan. Once this is done, the mover is ready for operation. The remote control will allow

you to move your caravan in any direction.

Please be aware that certain installations in Germany are subject to further technical requirements

than in the rest of Europe. If after installation the caravan mover has easily accessible exposed

sharp edges not covered by the caravan bodywork, it is likely that an additional cover will need to be

installed. Please contact Purple Line for further assistance and see ‘Optional tting adapters’ where

these optional covers are listed with installation explained.

The chassis clamps provided are suitable for tment onto most standard caravan chassis that have

an L-shape or U-shape prole. Please refer to Fig.11 & Fig.12 for reference on dimensions and

clearances BEFORE you proceed any further with installation. If your chassis has different dimensions

to those shown in Fig.12 then various chassis clamp adapters are available to suit the majority of UK

and Continental caravans; please refer to the section entitled ‘Optional Fitting Adapters’.

Model Number QUATTRO600 / QUATTRO500 EGO500

Operational Voltage 12 Volt DC 12V DC

Average Current Consumption* 20A (approx.) 25A (approx.)

Maximum Current Consumption** 120A 120A

Speed 12cm/s (approx.) 12cm/s (approx.)

Approx. Net Weight (inc. all xings and

accessories) 29kg (approx.) 31kg (approx.)

Safe Working Load (SWL) Twin Motor/Quad

Motor 2500kg / 3500kg 2250kg / 3500kg

Minimum Width (caravan/trailer) 1800mm 1800mm

Maximum Width (caravan/trailer) 2500mm 2500mm

Power Source (caravan leisure battery) 12V 12V

* Average Current Consumption readings when using an approx. 1100kg single axle caravan on a hard, level surface.

** Maximum Current Consumption readings when using an approx. 1100Kg single axle caravan ascending a 1:4 (25%) gradient.

15 EN

Read this User Manual carefully before installation and use. Failure to comply with these

rules could result in serious injury or damage to property.

Before starting installation of the caravan mover:

DO check that the caravan is disconnected from the battery supply and the mains electrical supply.

DO only use adapters and accessories that are supplied or recommended by the manufacturer.

DO check that the tyres are not over worn (tting to new or nearly new tyres is the best option).

DO make sure that the tyre-pressures are correct to the manufacturer’s recommendation.

DO make sure the chassis is in good condition without any damage and is free from rust, dirt etc.

DO stop work immediately if you are in doubt about the assembly or any procedures and consult one

of our engineers.

DO locate the battery isolation switch to be accessible at all times when parking and moving the

caravan.

DO NOT remove, change or alter any parts of the chassis, axle, suspension or brake mechanism.

DO NOT operate the unit if you are under the inuence of drugs, alcohol or medication that could

impair your ability to use the equipment safely.

These instructions are for general guidance. Installation procedures may vary depending on

caravan type.

Use appropriate support! Working under a vehicle without appropriate support is extremely

dangerous. If you are tting the mover system yourself, it is advisable that the installation is

conducted by two people, as the mover will need to be raised up to the bottom of the

caravan’s chassis before the clamps can be installed.

Remember to complete the product registration form with the serial numbers of each motor

assembly prior to tting (see details within the Guarantee section of this manual).

If with your particular model of mover the motors are not pre-assembled onto the framework,

please follow assembly manual supplied in the motor packaging.

Installation - Safety Guidelines

16 EN

Loosely assemble motor framework side (1), motor framework side (2) and main cross bar (3) (see

Fig.1). The nuts (Fig.1B) on the cross bar (3) must be no more than nger-tight at this stage.

Place the assembly (Fig.1) loosely under the caravan. In principle, the unit should be tted in front of

the caravan road wheels, but if tting in this position is not possible, it is permissible to t it to the rear

of the wheels by rotating the whole assembly by 180° degrees.

Loosely t the two clamping assemblies to the chassis (see Fig.10.1) and attach using the bolts, nuts

and washers (16,17,18) provided in the installation kit. Nuts must be no more than nger-tight.

Quattro Rhodium Mover with Manual Engagement:

Assemble the parts of the cross actuation bar (4 & 5) and connect them to the motor units (1 & 2) with

the nyloc nut and bolt (in bag of bolts) onto the cross actuation bar-connectors (see Fig.1A). Nuts must

be no more than nger-tight at this stage.

Make sure that the Main Cross Bar (3) and the Cross Actuation Centre Bar (4) are positioned in the

middle of the caravan/mover (the centre of the bar is marked).

With the main assembly loosely tted onto the chassis, slide the whole assembly along the chassis

until the rollers (Fig.2A or Fig.4A) are 20mm away from the surface of the centre of each tyre (Fig.5 or

Fig.7). Two 20mm spacers (30) are provided.

It is vitally important that each roller is at exactly the same distance away from the tyre. The

whole assembly must be parallel to the caravan/trailer axle.

Ideally, align the roller(s) with the centre of each tyre, if clearances permit. Quattro Platinum: When

positioning, always ensure there is at least 10mm of clearance between the gearbox and the tyre (Fig

9). Quattro Diamond/Rhodium: If the roller widths exceed that of the tyre, ensure that the outer roller is

aligned with the outer wall of the tyre. Overhang on the inside wall of the tyre is acceptable on thinner

tyres, and will not affect function or grip. If there is an obstruction preventing the rollers from being

mounted centrally, then moving the mover inboard to suit is acceptable as long as at least one roller

makes full contact on the tyre with the second (inner) roller making partial contact.

Installation - Mechanical Components

Place the caravan on a hard, level surface. The use of a lifting ramp or an assembly pit is ideal

for access and personal safety.

Clean the area of your chassis where you need to mount all components to ensure a good tting.

Unpack all the components and check for the presence of all parts (see Package Contents List).

Make sure the caravan is prepared for installation. Check before installation that important areas,

such as drains/spare tyre etc. do not cause any obstruction to the function of the mover.

Ensure both rollers are in the DISENGAGED position (Fig.5 or Fig.7), as the unit will not t

correctly otherwise.

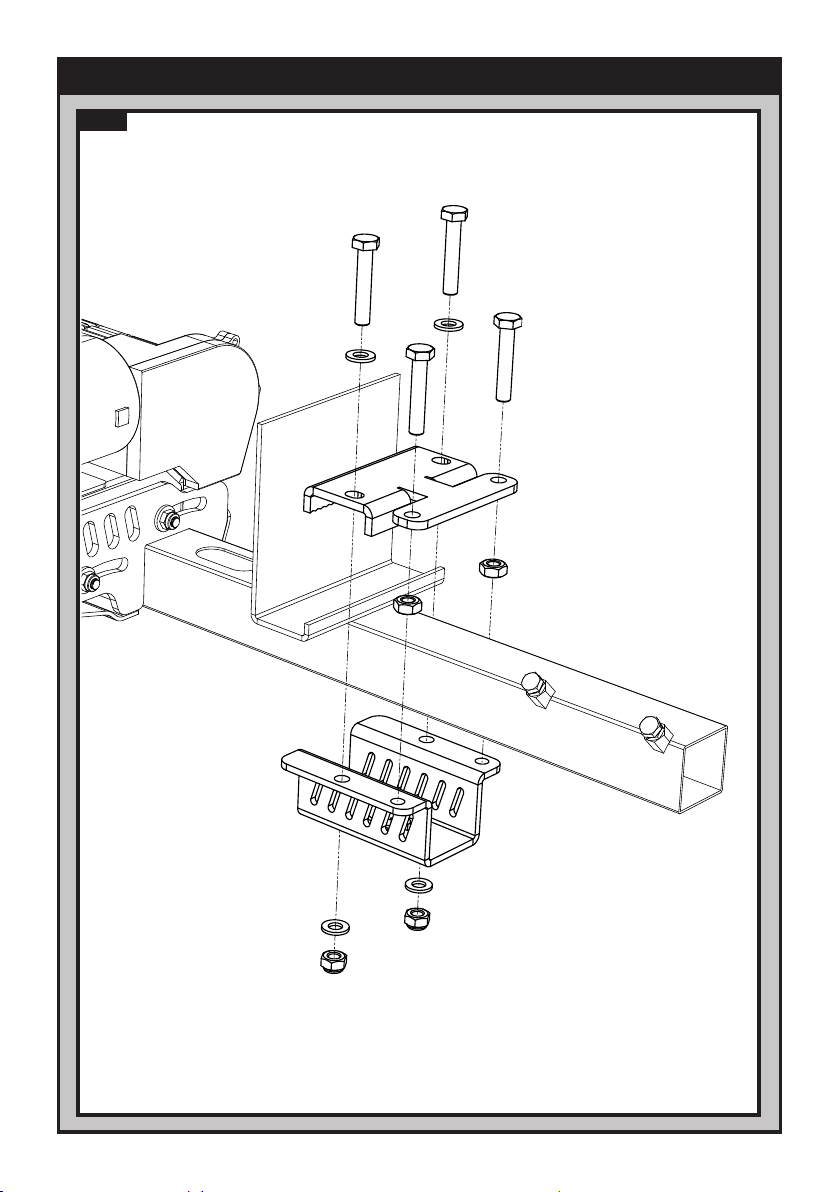

Installation - Classic Clamp System (Fig.10.1)

17 EN

Installation - Classic Clamp System (Fig.10.1) cont.

Loosely assemble the main cross bar (3) inside motor framework side (1) and motor framework side

(2) (see Fig.1). The nuts/bolts (Fig.1B) on motor framework (1&2), must be no more than nger-tight at

this stage.

Place the assembly (Fig.1) loosely under the caravan. In principle, the unit should be tted in front of

the caravan road wheels, but if tting in this position is not possible, it is permissible to t it to the rear

of the wheels by rotating the whole assembly by 180° degrees.

Typically the Shark Clamp will be pre-assembled onto the motorsides for ease of tting, but if the

clamps have been purchased separately or are not pre-assembled, they should be assembled onto

the framework as shown in (Fig.15). Before attempting to install the mover onto your caravan chassis

ensure that the fastening nuts (Fig.10.2E) are tightened, xing the rear bolts (Fig.10.2B) in place,

allowing the top jaw (Fig.10.2.C) to translate in the vertical axis.

With xing nuts and bolts loosely installed (Fig.10.2A and F), slide the top jaw (Fig.10.2C) up to open

the jaws of the clamp at one motorside. Hook the top jaw onto the caravan chassis, allowing the

motorside to hang in place. Repeat this process with the second motorside so that the full assembly is

suspended in place.

With the crossbar nuts/bolts loose (Fig.1B), adjust the lateral position of each motorside so that the

rollers are central to the tyre, or as close to the centre as possible, ensuring 10mm of space is left

between the tyre and gearbox for the Quattro Platinum (Fig.9). After adjusting ensure the clamps

haven’t moved out of position by holding the framework motorside rmly, while reaching round and

pushing the clamps outwards until the fastening bolts and chassis are within 1-2mm of each other.

Once happy with the overall width of the mover system, tighten crossbar nuts/bolts (Fig.1B) to

9ft lbs/12Nm to set the width.

Slide the whole assembly along the chassis until the rollers (Fig.2A or Fig.4A) are 20mm away from

the surface of the centre each tyre (Fig.5 or Fig.7). Two 20mm spacers (30) are provided. Fully tighten

the clamp bolts (Fig.10.2A) on both clamping assemblies to a torque setting of 40 ft lbs/55Nm. When

tightening one clamp bolt, the other may loosen slightly so it may take several passes to get both bolts

fully torqued on each clamp. A tip is to do all clamp bolts up until there is a strong resistance before

torquing fully.

Note that no tightening/torquing of the rear nuts/bolts (Fig.10.2B and E) is required. These

components are in place purely to assist with the installation process and are not a method of

afxation.

Installation - Quick-t Shark Clamp System (Fig.10.2)

Fully tighten the four nylock nuts (17) on both clamping assemblies (Fig.10.1) to a torque setting of 40

ft lbs/55Nm, then the four bolts (Fig.1B) on the Main Cross Bar (3) and the four bolts (Fig.1C) on Cross

Actuation assembly (4 & 5) to a torque setting of 9ft lbs/12Nm. Re-check the distance of 20mm from

the rollers to the tyres and if necessary, loosen the bolts and re-adjust the position of the assembly.

Once satised with the position of the assembly, t and tighten the Chassis Stop Nuts & Bolts (7) ,

one pair in each of the Upper Classic Clamp Plates (see Fig.10.1). Tighten to a torque setting of 40 ft

lbs/55Nm. The Stop Bolts grip the lip of the chassis and help prevent the mover from sliding along the

chassis. The main mechanical components have now been installed.

18 EN

Installation - Electrical/Electronic Components

Operation and Maintenance

Please refer to manual supplied with electronics for wiring installation, operation instructions

and troubleshooting.

Alternatively, for Smart Electonics visit www.purpleline.co.uk/qtr-m005

or for Basic Electronics visit www.purpleline.co.uk/qtr-m003

It is possible to position the caravan’s hitch exactly over a stationery car’s tow ball using the

mover. But please be very careful!

Hitch the caravan in the normal way ready for towing.

Release the rollers from the caravan’s tyres. You cannot tow the caravan with the Mover

engaged! Make sure that both rollers are fully disengaged!

Trying to drive away with the mover still engaged, will damage the mover, your caravan tyres

and strain your tow vehicle!

To prevent the battery from becoming totally discharged during long periods of inactivity it must be

disconnected and recharged before using again.

Please check regularly that the rollers of the drive units are free of any dirt, or debris that may have

been picked up from the road. Any further maintenance is not required.

Please check regularly the distance between the rollers and the tyres. In the neutral (fully disengaged)

position this must be 20mm.

When your caravan is stored for an extended period of time (over winter for example) it is

recommended to remove the leisure battery from the caravan. Make sure you keep it charged to

ensure it is in good condition the next time you want to use it.

Once a year have your caravan mover maintained and visually inspected. This inspection must include

all the bolt/nut connections, the cables and electrical connections and lubrication of movable parts/

joints.

In case of any failures or problems, please contact your Caravan Mover supplier.

19 EN

Product Registration

Please register your Quattro® caravan mover online within 14 days of purchase. Registration is quick

and simple, go to www.purpleline.co.uk/product-registration. Please retain your original purchase receipt.

Please ll-in the Serial Numbers + additional information and retain this manual for future

reference. The serial numbers can be found on the product label on each of the motor sections. The

serial number can be up to 18 digits long. Please make a note of your serial numbers in the section

below for future reference. The serial numbers will be required for product registration.

Motor Serial No.

Date of Purchase

Name of Dealer

Guarantee

Quattro®caravan mover systems are provided with a UK parts only warranty for a period of 7-years

which includes the rst 12 months statutory, plus an additional 6 years extended warranty. Please note

that the extended 6year warranty is only offered if Product Registration is completed and returned within

14 days from the date of purchase. Any warranty claims must be directed through the place of purchase

with a proof of purchase provided. Warranty cover is limited to products within UK mainland only.

Within the seven year period, the manufacturer will, at their sole discretion, replace or repair any parts

that have failed if deemed to be due to a manufacturing defect.

The manufacturer does not take responsibility for any consequential loss whatsoever.

Upon inspection, components that are missing when checked against the packing contents list must

be reported to the place of purchase within 5 working days.

This warranty cover is available only to the original purchaser of the product and is non-transferable.

What is not covered:

- Normal wear and tear.

- Damage that is deemed to be due to customer misuse or neglect.

- The cost of repair following accidental damage, abuse of product or deliberate tampering.

- Warranty is not offered for any type of trade or commercial usage.

- As a result of the recall or modication of all equipment in a model range.

- Force Majeure e.g. Damage caused by extraordinary events or circumstance beyond anyone’s control.

- Damage as a consequence of water ingress.

- Carriage or any additional charges incurred including travel or labour.

- Caravan electrics, including fuses, plugs, batteries, wiring connections and looms. Scratches, dents,

paintwork and cosmetic trim.

- Damage as a result of incorrect installation and/or disregard to manufacturers tting instructions.

- Cover will not be given to any part or component which is out of manufacture or no longer available.

- Cover will not be given if the product has been modied in any way.

- Damage occurring as a result of the product being used outside manufacturer’s load recommendations.

20 EN

Low Prole Chassis Adapter Plates (Part No. CM-029)

If your chassis frame height is less than 140mm these plates must be tted to lower the

assembly to provide the correct height of 185mm. Drilling of your chassis may be required.

Note: In some countries, the installation must be checked by a professional technician in order

to adhere to local regulations.

Narrow Gauge Chassis Adapters (Part No. CM-030)

These plates must be utilised if you have an AL-KO Vario III/AV chassis which has a frame

thickness of less than 2.8mm. These must be positioned behind the axle using pre-drilled holes

already available on the chassis; so your mover must be tted behind the axle.

16mm Spacers - 1 pair (Part No. CM-028/Q)

Use spacers to lower the mover assembly if your chassis has a frame height of between 140

to 185mm. A maximum of 3 sets of spacers can be utilised to achieve correct frame height of

185mm. A set of extended clamp bolts must be used in conjunction with these spacers (Part

No. CM-031).

[For use with Classic Clamp only.]

Set of 8 M10 x 100 Bolts (Part No. CM-031)

Set of 8 extended clamp bolts for use with 16mm spacers.

[For use with Classic Clamp only.]

Quattro500/600 Cover

(Part No. QTX10009 [LH] QTX10010 [RH])

Plastic cover for use in certain installations subject to further

technical requirements in Germany. If after installation the caravan

mover has easily accessible exposed sharp edges not covered by

the caravan bodywork, it is likely that this additional cover will need

to be installed.

Please contact Purple Line for further guidance and installation

detail.

EGO400/500 Cover

(Part No. QTX10006 [LH] QTX10007 [RH])

Plastic cover for use in certain installations subject to further

technical requirements in Germany. If after installation the caravan

mover has easily accessible exposed sharp edges not covered by

the caravan bodywork, it is likely that this additional cover will need

to be installed.

Please contact Purple Line for further guidance and installation

detail.

Additional chassis clamp adapters shown below are available for purchase:

Optional Fitting Adapters

This manual suits for next models

2

Table of contents

Languages:

Other Quattro Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction