Content

Ⅰ. Safety Instruction ................................................................................................................................................. 2

Ⅱ. Summary .............................................................................................................................................................. 3

Ⅲ. Feature ................................................................................................................................................................. 3

Ⅳ. Specifications ....................................................................................................................................................... 3

Ⅴ. Setting & Operating the Soldering Station .......................................................................................................... 4

5.1 Iron Holder and Sponge ............................................................................................................................... 4

5.2 Connection ................................................................................................................................................... 4

5.3Turn on/off .................................................................................................................................................... 4

5.4 Setting the Temperature ............................................................................................................................... 5

Ⅵ. Setting Working Parameters ................................................................................................................................ 6

6.1 Enter into SET menu.................................................................................................................................... 6

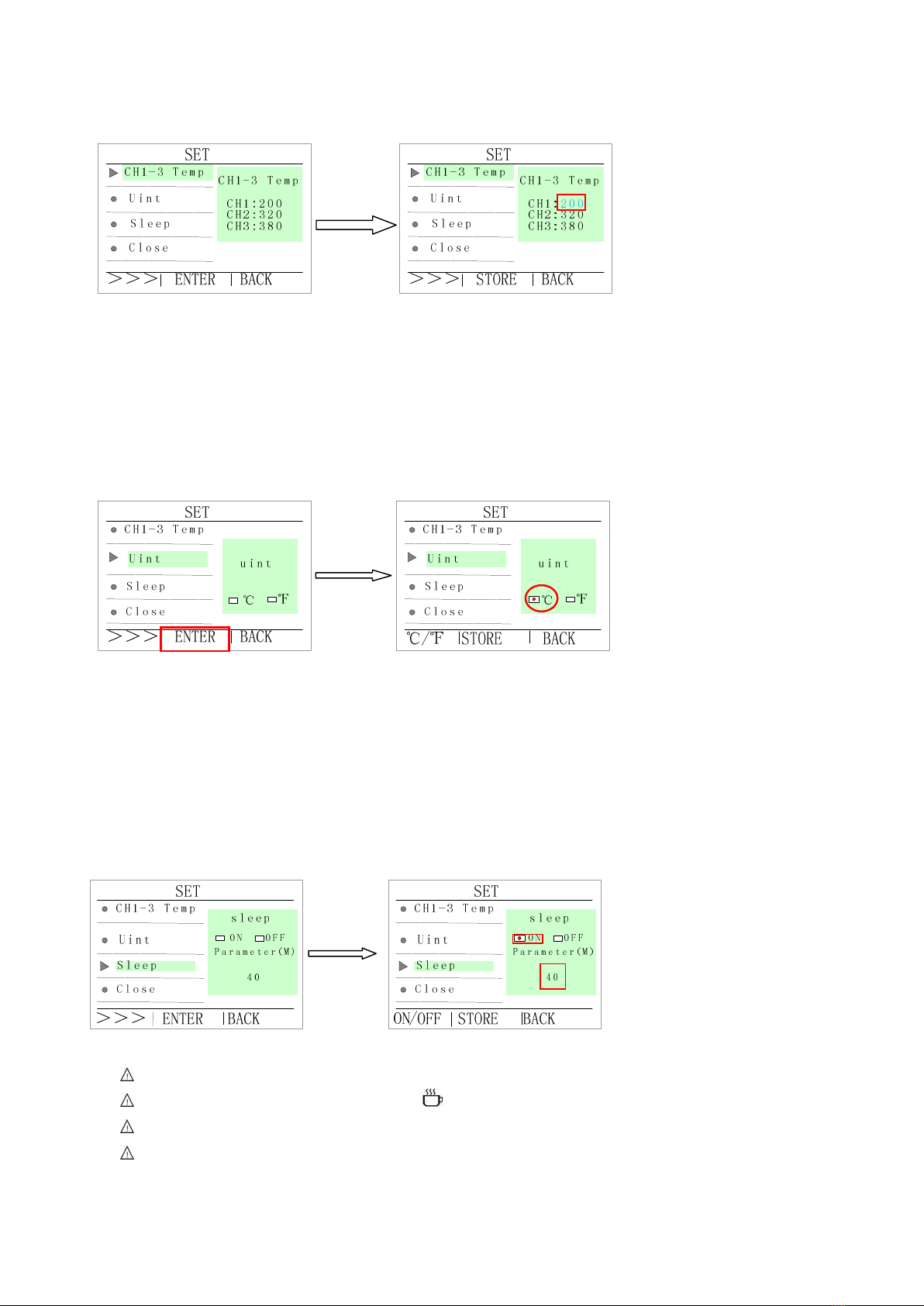

6.2 Temperature setting ...................................................................................................................................... 6

6.3 Temperature unit setting .............................................................................................................................. 7

6.4 Sleep time setting ......................................................................................................................................... 7

6.5 Close time setting ........................................................................................................................................ 8

6.6 Alarm temperature+ setting ......................................................................................................................... 8

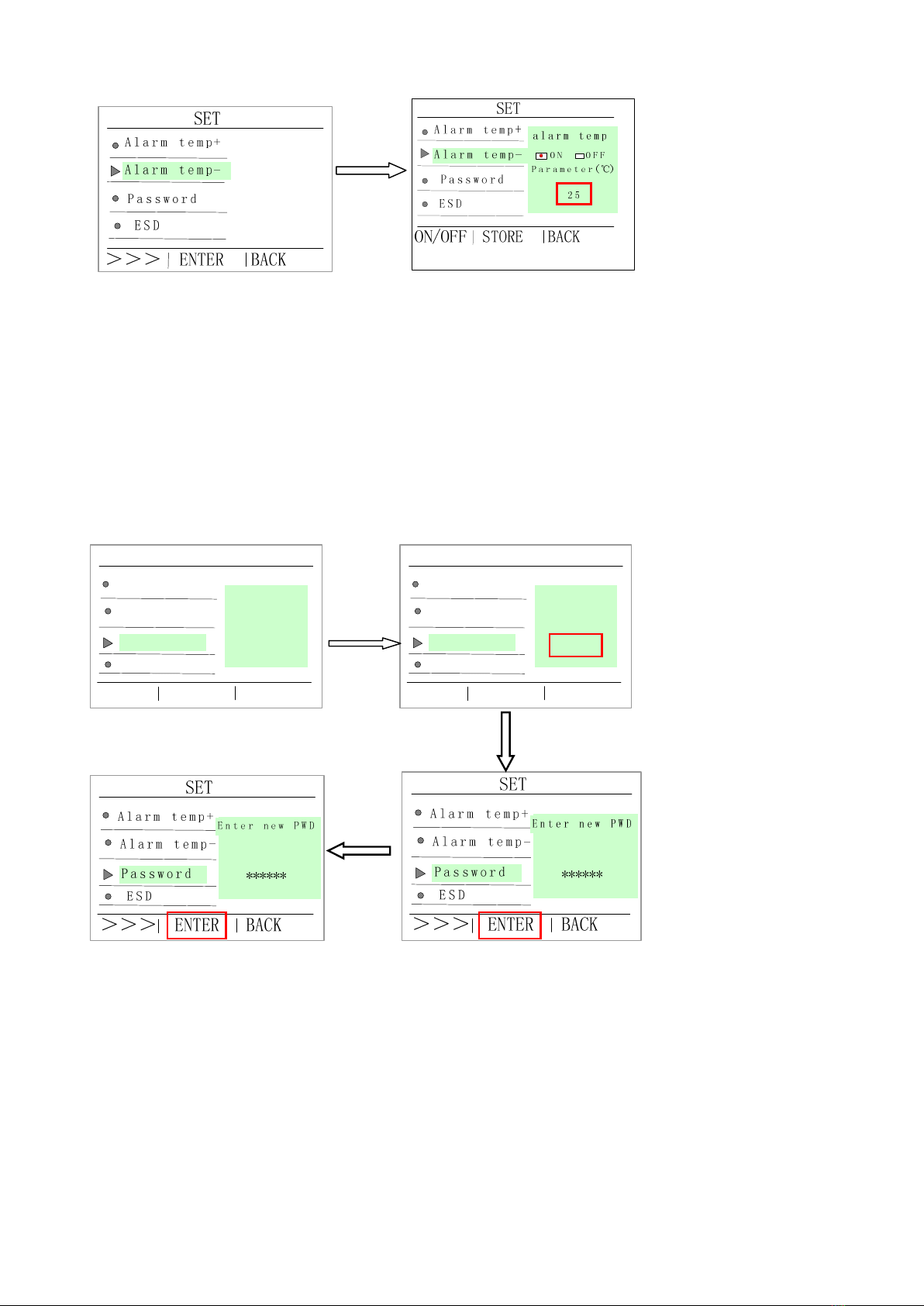

6.7 Alarm temperature- setting .......................................................................................................................... 8

6.8 Change password ......................................................................................................................................... 9

6.9 ESD .............................................................................................................................................................. 9

6.10 Key tone setting ....................................................................................................................................... 10

6.11 Address setting ......................................................................................................................................... 10

6.12Language setting ........................................................................................................................................11

Ⅶ.Calibrating the Temperature ................................................................................................................................11

Ⅷ、Tip Care and Maintenance ................................................................................................................................11

Ⅸ.Error messages .................................................................................................................................................... 13