QK-CE220BATRL ENGLISH

www.quiko.biz 10

drives the two motors without 2nd motor delay if the DEL trimmer is turned fully counter-clockwise, with a 2nd

motor delay of 3 seconds for all the other positions of the DEL trimmer.

- activates the operator for one second at maximum speed and then at the speed set with the “FOR” trimmer.

- the opening terminates when the limit switch or the obstacle detection device are triggered or the manoeuvre

time has elapsed. If other commands are given during opening, they will have no effect.

- with the automation stopped and in automatic standby each time the timer restarts from zero.

When the standby time has elapsed, the closing manoeuvre occurs and the control unit:

- carries out a fixed one second pre-flash

- drives the two motors with a 2nd motor delay as set on the DEL trimmer

- if other commands are issued during closure, the control unit carries out a complete re-opening.

- the closure terminates when the limit switch or the obstacle detection device are triggered or the manoeuvre

time has elapsed.

ATTENTION: Maintaining the opening contact (“STR” terminal) closed, with a temporised relay for

example, the control unit will command opening and the automation will remain open with automatic

closing disabled until the contact is re-opened again (Company Function).

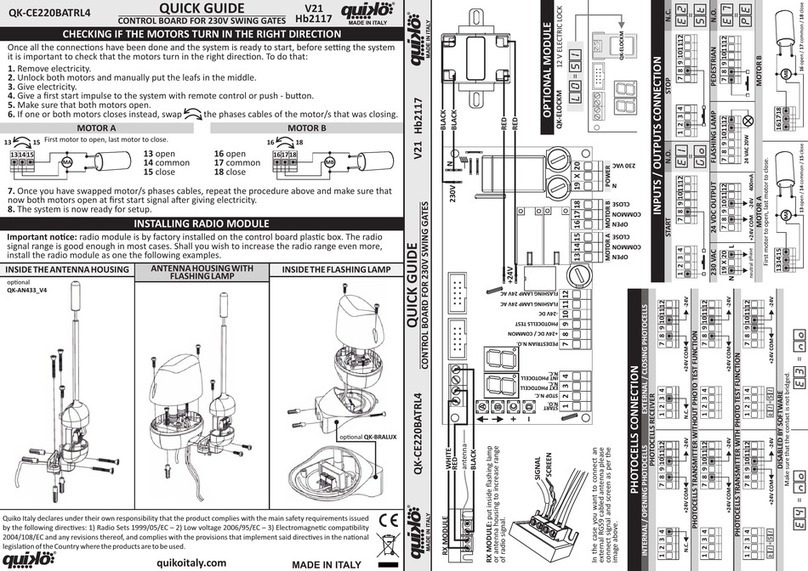

5.5.2 Step by step mode without automatic closing

Switch the dip-switch 6 to ON and the dip-switch 7 to OFF.

The step by step command sequence is OPEN-STOP-CLOSE-STOP

The opening and closing manoeuvres take place as described in the previous paragraph.

5.5.3 Step by step mode with automatic closing

Switch the dip-switch 6 to ON and the dip-switch 7 to ON.

The step-step logic is OPEN/STOP/CLOSE/STOP.

When the opening manoeuvre has been completed and the pause time set on the PAU trimmer has elapsed the

control unit effects automatic closing.

If, when the automation is closed, a radio command is given, either through the “STR” input command or the

START pushbutton on the board, the control unit:

- commands a one second fixed pre-flash

drives the two motors without 2nd motor delay if the DEL trimmer is turned fully counter-clockwise, with a 2nd

motor delay of 3 seconds for all the other positions of the DEL trimmer.- the opening terminates when the limit

switch or the obstacle detection device are triggered, the manoeuvre time has elapsed or there is a radio or

manual command. In the latter case, the control unit disables the automatic closing and to restart the

manoeuvre, a further command is required.

If the automation is completely open, once the standby time has elapsed the closing manoeuvre occurs and the

control unit:

- carries out a fixed one second pre-flash.

- drives the two motors with a 2nd motor delay as set on the DEL trimmer

- the closing terminates when the limit switch or the obstacle detection device are triggered or the manoeuvre

time has elapsed.

5.5.4 Automatic closing and rapid re-closing mode

Switch the dip-switch 6 to OFF and the dip-switch 7 to ON.

Switch the dip-switch 3 to ON.

The control unit does the following:

a) if the photocell is triggered during opening, the control unit continues the opening, and when the photocell is

cleared effects a STOP followed, after one second, by the re-closure.

b) if the photocell is triggered during standby with the gate open, when the photocell is cleared, after one

second, automatic re-closure occurs.

c) if the photocell is triggered during closure, the control unit effects an inversion and, when the photocell is

cleared, it effects a STOP followed, after one second, by the re-closure.

If, during the opening cycle or during standby, the photocell is not triggered, the pause time is that which is set

with the “PAU” trimmer.

5.5.5 OPEN-CLOSE-OPEN mode

Switch the dip-switch 6 to OFF and the dip-switch 7 to OFF.

If, when the automation is closed, a radio command is given, either through the “STR” input command or the

START pushbutton on the board, the control unit:

- commands a one second fixed pre-flash

- drives the two motors without 2nd motor delay if the DEL trimmer is turned fully counter-clockwise, with a 2nd

motor delay of 3 seconds for all the other positions of the DEL trimmer.

- the opening terminates when the limit switch or the obstacle detection device are triggered or the manoeuvre

time has elapsed. If other commands are given during opening, they will not have any effect.

When the automation is completely open, to start the closing manoeuvre give a radio or manual command and

the control unit: