QR 325 Quincy Compressor

50215-106, January 2014 1 3501 Wismann Lane, Quincy IL - 62305-3116

INTRODUCTION

This manual provides information for the following

QR-25 Series, Model 325 (Record of Change 106)

compressor versions:

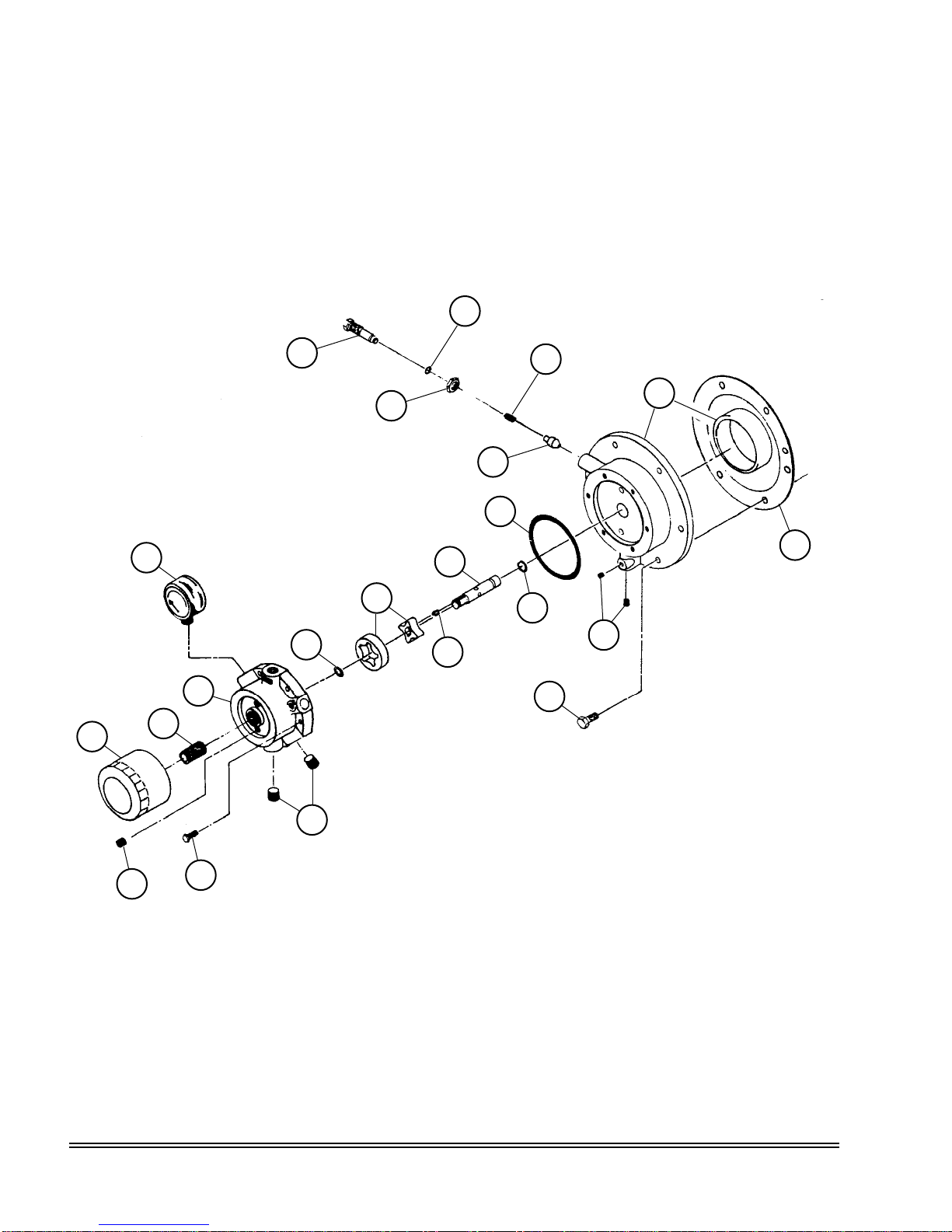

L Control Version L

head assembly with 1 unloader tower &

a hydraulic unloader

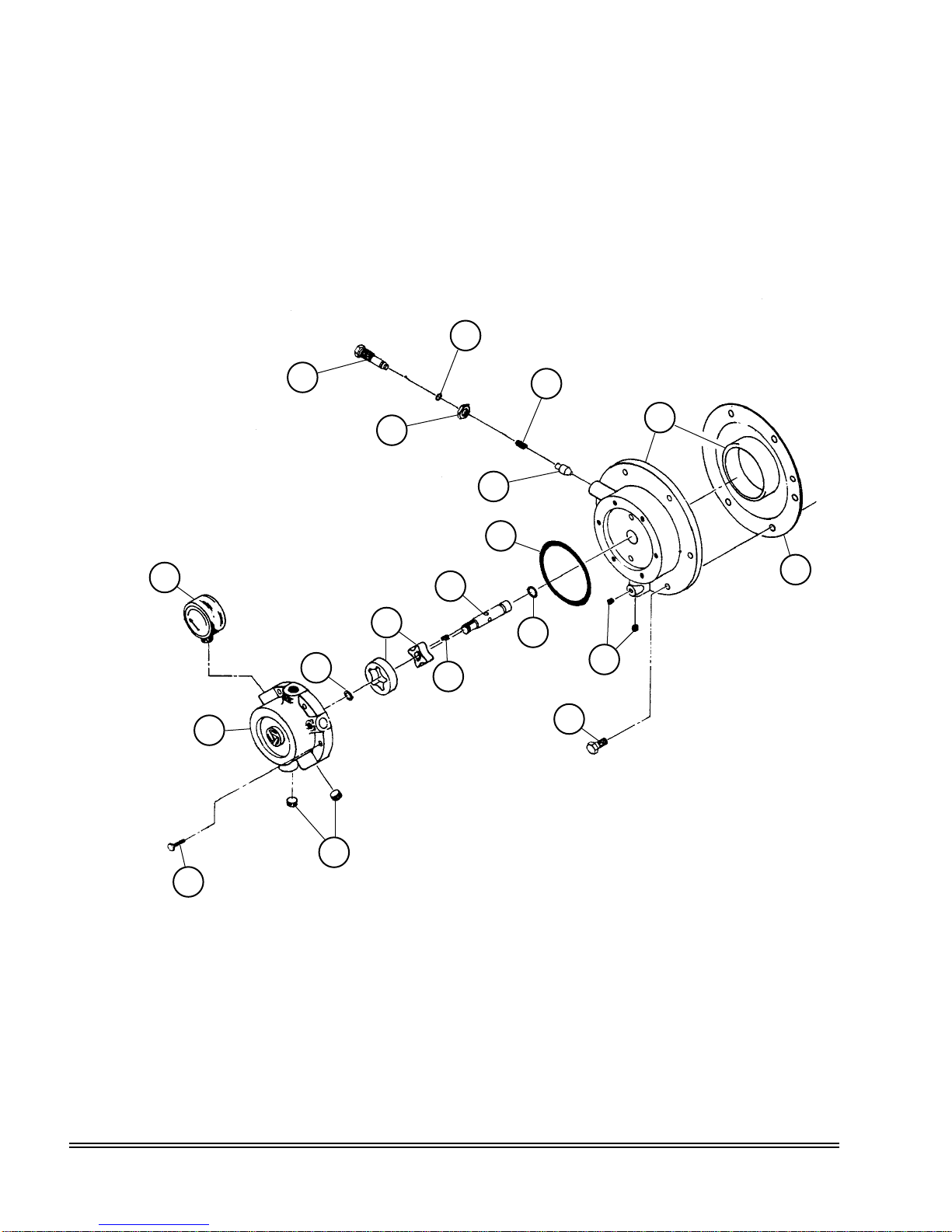

LS Control Version LS

head assembly with 2 unloader towers, a

hydraulic unloader, & a pilot valve with

a check valve assembly

LVD Control Version LVD

head assembly with 2 unloader towers, a

hydraulic unloader, & a pilot valve with

a lockout & check valve

These compressors are aircooled, two stage, two

cylinder, pressure lubricated compressors, with up

to 200 PSI continuous pressure capability (201 to

500 PSI intermittant pressure capability with proper

configuration; consult factory). The Model 325 has a

4.5" low pressure piston bore and a 2.5" high pres-

sure piston bore and a 3" stroke and can be run at

400-900 RPM.

Available options included in this manual:

-high pressure rated cylinder and head

-spin-on oil filter

-hooded air filter

-hooded air filter / silencer

CHANGES

since previous printing dated October 2006:

Control groups were redesigned.

TABLE OF CONTENTS

..................................2

.................................2

.................................................2

..............................2

................................................3-4

.................................................5-6

......................................................7-8

....................................................9-10

...............................................11-12

................................................13-14

.........................................15-16

............................17-18

.........................................19-20

............................21-22

............................................................23

..........................................................24

.......................................................25

............................................................26

...................................26

...................27

.............................................................28

.........................................................................28

.................................29

....................................................................29

.........................30-32