MAN-000020-00 REV A 3

Chemical Hazard. Working with lead-acid batteries may result in exposure to

highly corrosive acid. To protect eyes and skin, use the required Personal

Protective Equipment (PPE)as mandated by your employer and local

regulations. At a minimum, wear safety goggles and skin protection while

connecting the battery charger or working in the vicinity of lead-acid batteries.

Follow the battery manufacturer's published instructions when installing,

charging, and servicing batteries.

Use only with rechargeable batteries. Do not attempt to charge other battery

types; doing so may cause equipment damage and result in serious personal

injury.

Do not expose the charger to rain or snow. The charger is NOT designed for

outdoor use.

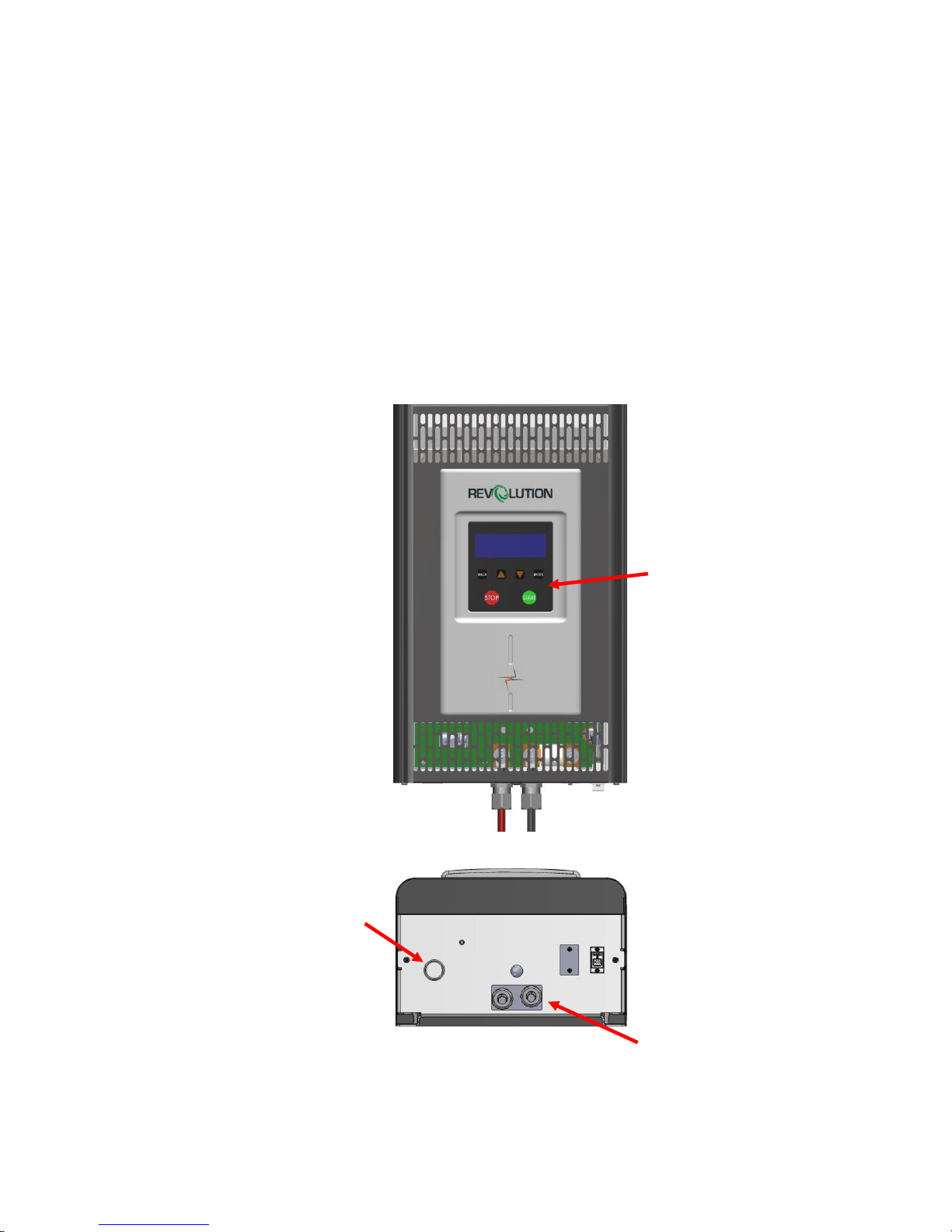

Adequate Cooling Required. To prevent damage from overheating, proper

airflow must be ensured. Do not restrict fan inlets or exhaust outlets. Do not

mount the charger in a confined space or where the exhaust air will recirculate.

No User Serviceable Parts.If service is required, contact Power Designers USA

LLC or its service representative.

These instructions assume a certain level of competence by the installer

and/or user. The following practices and codes contain relevant information, and

should be consulted for safe installation, testing, handling, and maintenance of

rechargeable lead-acid batteries. All applicable state and local codes must be

followed.

National Electrical Safety Code (NESC), ANSI/IEEE C2-2007 (or latest

revision). Copies may be obtained by contacting: The Institute of Electrical

and Electronics Engineers, Inc. (IEEE), Publications Office, 10662 Los

Vaqueros Circle, P.O. Box 3014, Los Alamitos, CA 90720

www.ieee.org

National Electrical Code (NEC) NFPA-70 (or latest version) available from:

National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269

www.nfpa.org