1. INTENDED USE

1) Auto-Darkening Welding Helmets are designed to protect the eye and face from sparks, spatter,

and harmful radiation under normal welding conditions auto-darkening filter automatically

changes from a light state to a dark state when an arc is struck. And it returns to the light state

when welding stops.

2) Auto-Darkening Welding Helmets comes ready for use. The only thing you need to do before

your welding is to adjust the position of the headband and select the correct shade number for

your application.

2. BEFORE WELDING

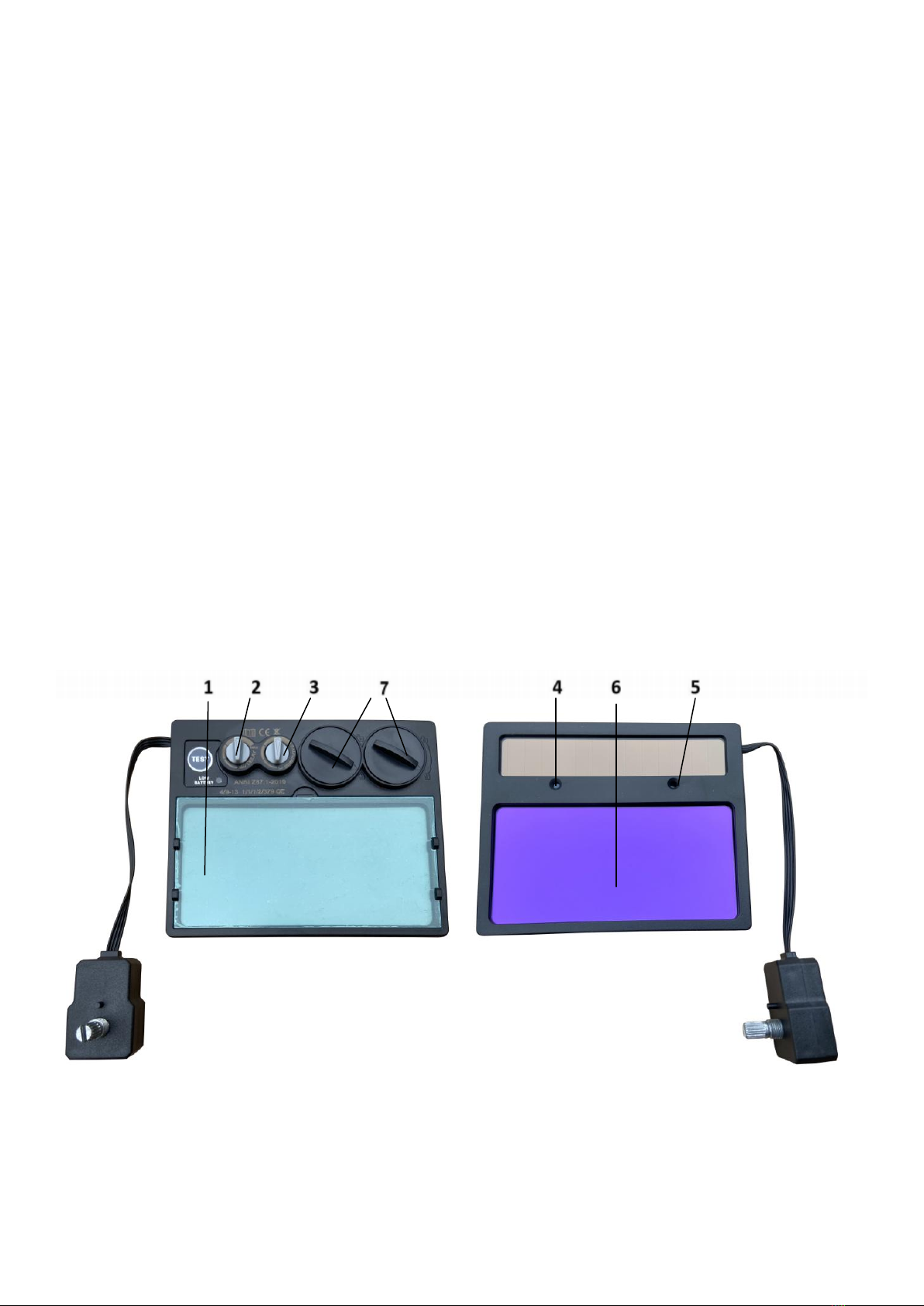

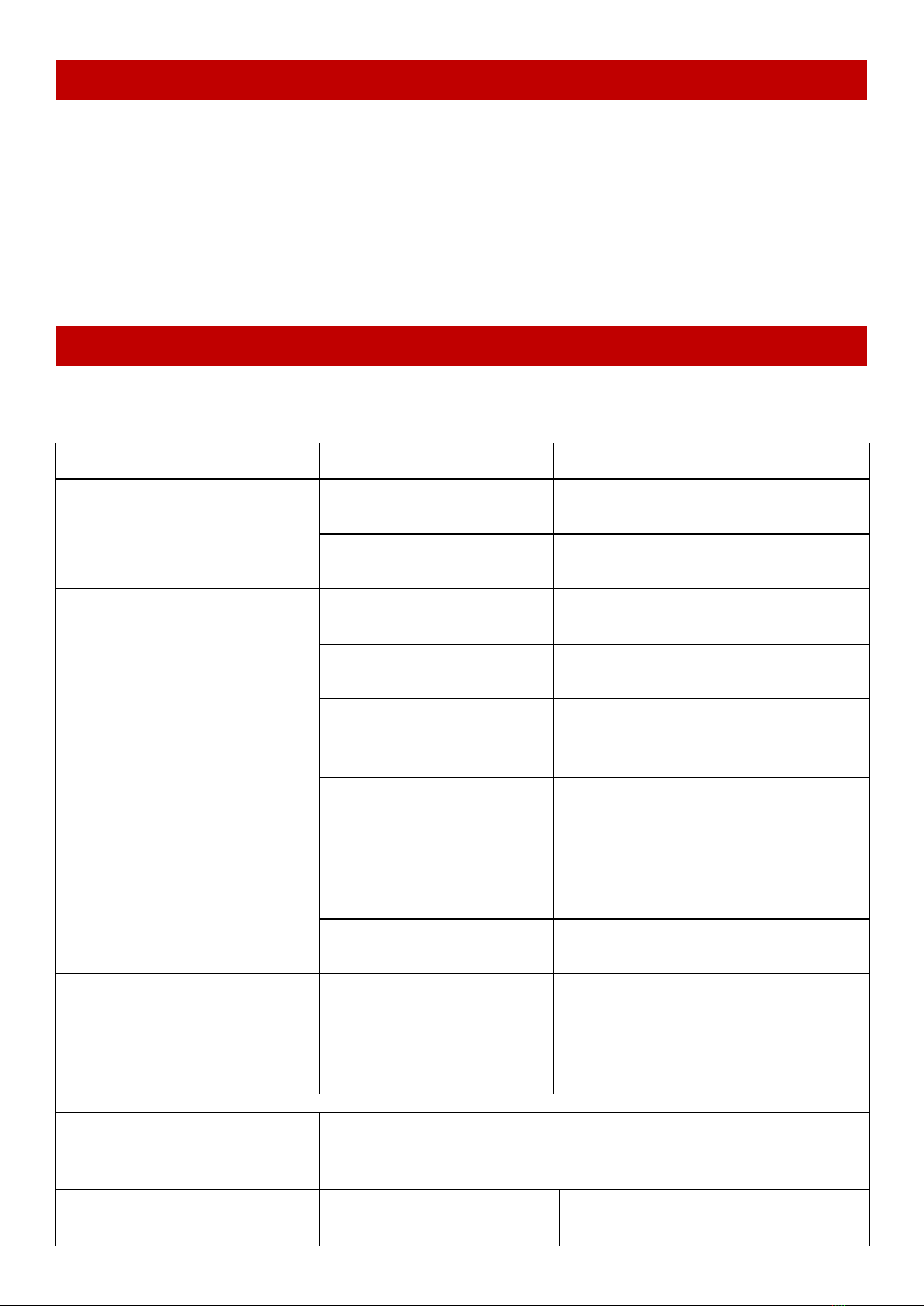

1) Check the front cover lens to make sure that they are clean, and that no dirt is covering the two

sensors on the front of filter cartridge. Also check the front/inside cover lens and the front lens

retaining frame to make sure that they are secure.

2) Inspect all operating parts before use for signs of wear or damage. Any scratched, cracked, or

pitted parts should be replaced immediately before using again to avoid severe personal injury.

3) Check for light tightness before each use.

4) Select the shade number you require at the turn of a shade knob(Seeing the Shade Guide

Table No.1). Finally, be sure that the shade number is the correct setting for your application.

5) Adjust headband so that the helmet is seated as low as possible on the head and close to your

face. Adjust helmet's angle when in the lowered position by turning the adjustable limitation

washer.

3. SAFETY WARNNING

WARNlNG: Severe personal injury could occur if the user fails to follow the

aforementioned warnings, and/ or fails to follow the operating instructions.

1) This Auto-Darkening Welding Helmet is not suitable for laser welding & oxyacetylene Welding.

2) Never place this Helmet andAuto-darkening filter on a hot surface.

3) Never open or tamper with the Auto-Darkening Filter.

4) This Auto-darkening welding helmet will not protect against severe impact hazards, including

grinding disks. Never use for grinding.

5) This helmet will not protect against explosive devices or corrosive liquids.

6) Don't make any modifications to either the filter or helmet, unless specified in this manual. Don't

use replacement parts other than those specified in this manual. Unauthorized modifications

and replacement parts will void the warranty and expose the operator to the risk of personal

injury.

7) Should this helmet not darken upon striking an arc, stop welding immediately and contact your

supervisor or your dealer.

8) Don't immerse the filter in water.

9) Don't use any solvents on filter’s screen or helmet components.

10) Use only at temperatures: -5°C ~ +55°C.

11) Storing temperature: -20°C ~ +70°C.

12) Protect filter from contacting with liquid and dirt.

13) Clean filters surfaces regularly, do not use strong cleaning solutions. Always keep sensors and

solar cells clean using a clean lint-free tissue/cloth.

14) Regularly replace the cracked/scratched/pitted front cover lens.