Software Installation

COM Port Setting

Connection Problems

Trouble Shooting

Installation and Help in Caseof

Connection Problems

The latest version of the RACO Tools setup

software can be downloaded from the

RACO website www.racointernational.com

under Products / Actuator Accessories /

Electronic Limit Switches in form of a ZIP

file. Download the ZIP file and store the

content in a separate folder. Extract the file

with all subfolders. To install RACO Tools

onto your laptop double click the Setup.EXE

file under administrative privileges. Please be

advised that with Microsoft Windows

operating systems Vista and Windows 7,

user rights have been changed. To properly

install the RACO Tools software the user has

to be locked in with administrative rights.

After starting the setup.exe software with the

right mouse click and selecting in the pull

down menu the setting install as

administrator, the RACO Tools software will

be installed hereafter automatically. Follow

the instructions during setup.

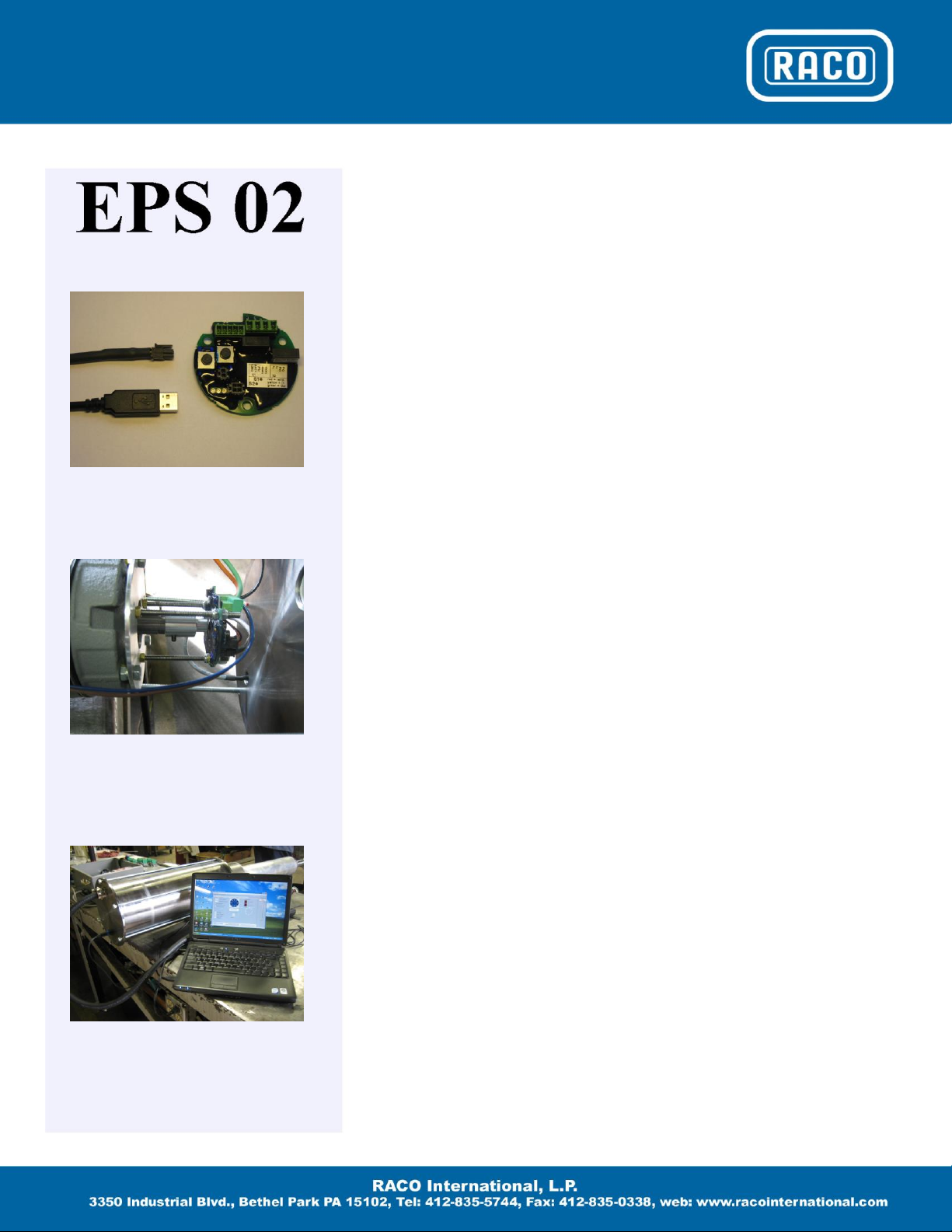

After installation of the RACO Tools

software, please check out the connectivity

between your laptop and the EPS02/EPS06

Electronic Position Sensor. Power up the

EPS02/EPS06 with a 24V DC power supply

and connect the TTL port (EPS02) / the USB

ports (EPS06) with an appropriate USB

cable. Start the RACO Tools application

program via the icon or the start program

menu.

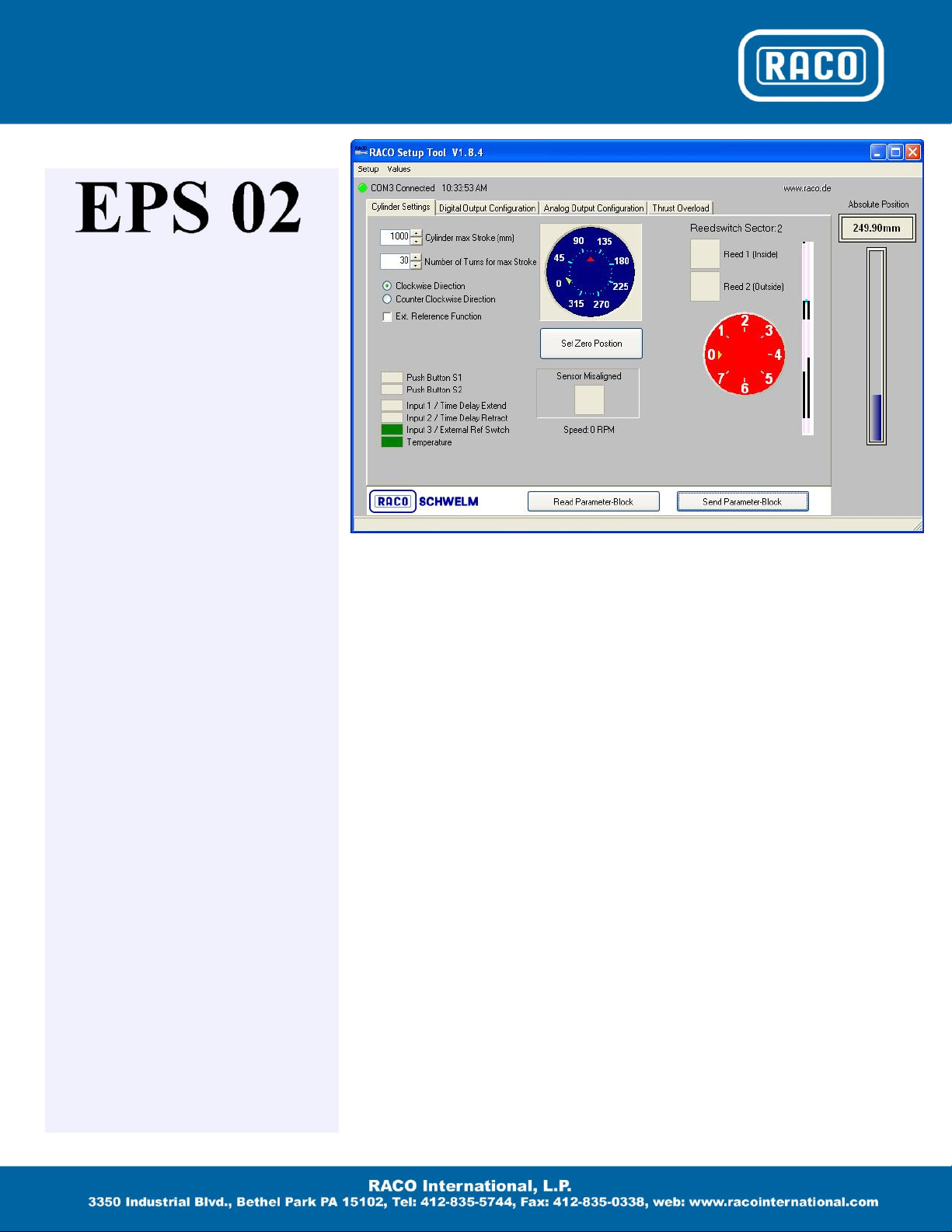

The connection is made successfully if the

LED symbol next to the text COM X

Connection in the upper left hand corner of

the main cylinder setting screen changes

fromred to green.

Connection Problem Trouble

Shooting

The most common problem is the

incorrect selection of the COM Port.

With the EPS02/EPS06 connected and

powered up please check under Control

Panel / System / Hardware / Device

Manager / Universal Serial Bus

Controllers that the communication

driver CP210x USB Composite Device

is loaded. Now click on Ports (COM &

LPT). The CP210x USB to UART

Bridge Controller should be loaded and

be pointing to the selected COM port

number. Use this COM port number in

conjunction with the RACO Tool

software. In the main RACO Tools

desktop window select the Setup pull

down command / Comport which will

open up a popup screen. Under Please

choose COM-Port select the assigned

COM port number and hit OK. The

LED symbol should change to green.

COM port numbers should be single

digit.

IF after the TTL / USB connection cable

is plugged into both the laptop and the

EPS02 / ESP06, and the CP210x USB

Composite Device is not loaded in the

device manager’s screen, the

communication driver has to be

installed manually. Please select the

subfolder USB and based on your

laptop’s operating system the

appropriate driver subfolder. Find the

file PreInstaller.exe and execute that

program. Follow the instructions of the

driver. Please make sure that you have

administrative rights.

There may be other vendor programs

installed on your laptop which may bind

the UART Controller to a driver

program during startup even if the main

program is not launched. These

programs are typically programs which

rely on a serial connection to talk to an

external device. One remedy is to de-

install that particular program or use a

different laptop.