5/6

RADIUS, LLC 4922 TECHNICAL DR. MILFORD, MI 48381

www.radius-eng.com

RADIUS EW SERIES

5. Electrical wiring

1) Before wring

1> Cable entries are machined with PG13.5 tap and sealed by Plug before delivery.

2> Please retain the plug to seal any unused entry.

3> Please make sure to seal the entries by using rubber or metallic packing after wiring, so that water or other

foreign material may not come in.

4> If suitable cable connection is not used for wiring, factory won’t guaranty the performance.

2) Electrical wiring

1> Check if electrical specification like as power, wiring & etc are correct or not.

2> Wiring diagram is to be supplied together with actuator (In vinyl pack or inside of top cover).

3> Do the wiring as per the given wiring diagram, such as power, control power, internal wiring and ground.

4> Make sure to supply electric power to heater for keeping inside of actuator clean and dry for anti-

condensation.

5> Make sure to check wiring to the terminal is strong enough.

6> Make sure that one relay operates one actuator only (Can not operate two or more actuators).

7> Make sure to clean inside of actuator and no foreign material inside.

6. Simple trouble shooting

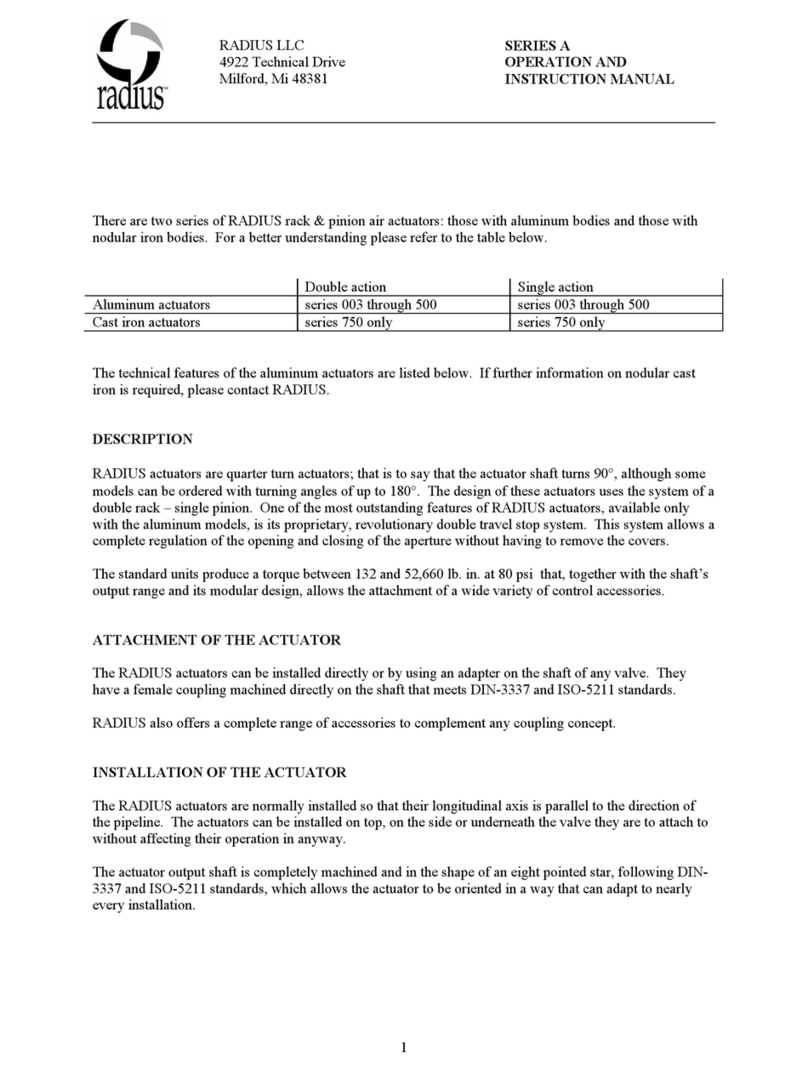

1) 110/220VAC 1Ph

Trouble Cause Counter plan

Check if power is on Power on

Check if voltage is too low Check power

Motor and supplied power is different Check motor power and supplied power

Wiring is not correct and tight or loosen Do wiring again tightly

Coil of motor is damaged Change the motor

Capacitor is damaged Change the capacitor

Actuator doesn’t work at

all

Setting of limit and torque switch is not correct Do setting switches again