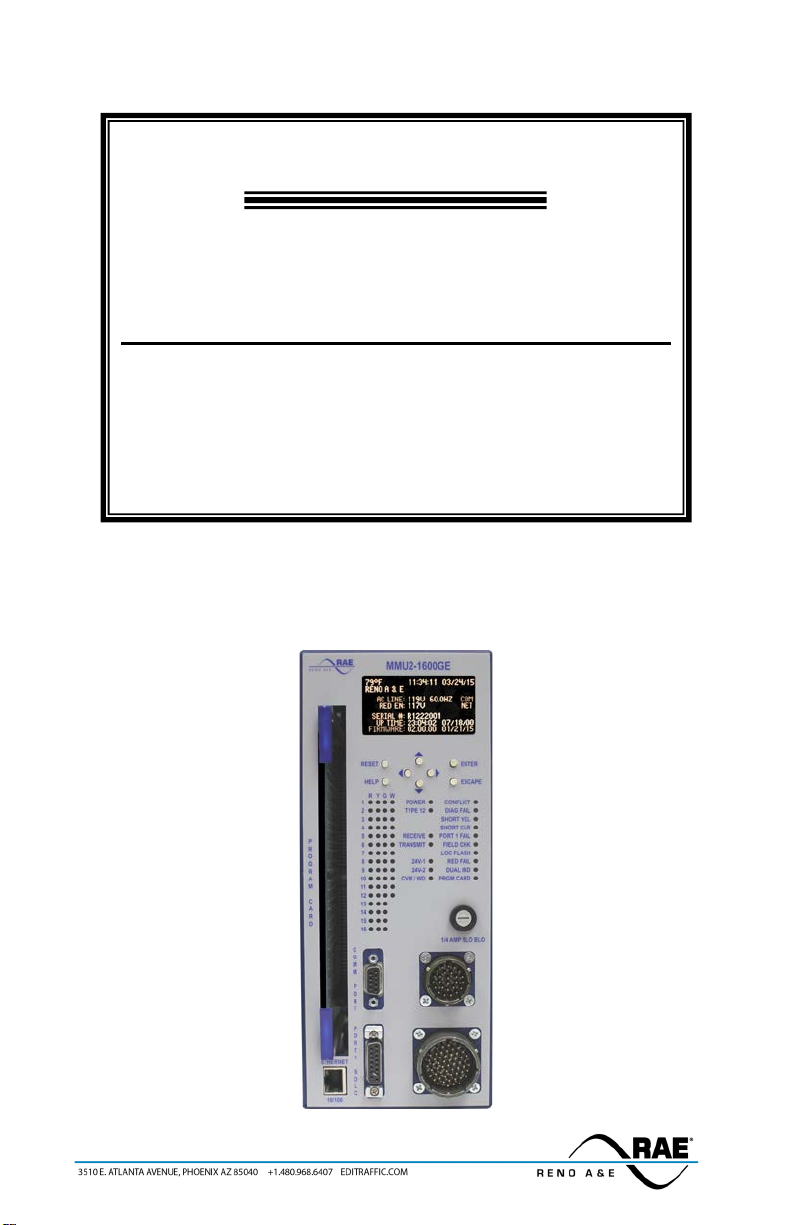

889-3819-00 MMU2-1600GE series Operations Manual Rev Apr 2020 Page 1of 51

Section 1 General Description

This product manual was written for people installing, operating, and maintaining the Reno A&E Model MMU2-

1600G Malfunction Management Unit (monitor).

The Reno A&E MMU2-1600G was designed to meet or exceed the standards defined in Section 4 of the NEMA

Standards Publication TS 2-2003 and Amendment 4-2012. Section 4 responds to the need for a monitor to

accomplish the detection of, and response to, improper and conflicting signals and improper operating voltages in a

Controller Assembly (CA). This standard provides interchangeability between units of different manufacturers and

downward compatibility to NEMA Standards Publication TS 1-1989. Amendment 4-2012 defines eight types of

Flashing Yellow Arrow (FYA) operation. The MMU2-1600G supports the eight FYA types defined in Amendment

4 and eight additional types of FYA operation.

The MMU2-1600G detects the presence of voltage on conflicting field connection terminals, the absence of proper

voltages on all of the signal field connection terminals of a channel, and monitors for the presence of satisfactory

operating voltages within the Controller Unit (CU) and the monitor itself. If any of these conditions exist or are

out of tolerance for the minimum time defined in Section 4 of the NEMA Standards Publication TS 2-2003, the

Output relay’s normally open contacts will transfer from the no fault state (relay energized) to the fault state (relay

de-energized). The closure of the Output relay contacts will cause the transfer of the traffic signals to Flashing

Operation. The fault is recorded by the MMU-1600G and displayed on the appropriate LED indicators.

The MMU2-1600G will operate in one of two modes depending on the signal level on the Type Select input. If the

Type Select input is at Logic Ground potential, the monitor will operate as a Type 16 monitor with sixteen

channels, otherwise it will operate as a Type 12 monitor with twelve channels.

Type 16 - Each of the sixteen channels monitors three 120 volt AC outputs; Green / Walk, Yellow, and Red /

Don’t Walk.

Type 12 - Each of the twelve channels monitors four 120 volt AC outputs; Green, Yellow, Walk, and Red.

For TS 2 type operation the MMU2-1600G is usually configured as a Type 16 monitor. The Type 16 monitor is

intended for those applications in which there are three circuits per channel and the monitor channels have been

wired in a one-to-one correspondence with the load switches, as defined in Section 5.5.3, Paragraph 9 of the

NEMA Standards Publication TS 2-2003. The Type 12 monitor is intended to provide downward compatibility

with a 12 channel conflict monitor unit (CMU) conforming to TS 1-1989.

The signal monitor portion of the monitor is capable of checking for the presence of voltage on conflicting field

connection terminals in the Controller Assembly. For the purpose of conflict determination, a signal on any of the

Green, Yellow, or Walk inputs associated with a channel shall be considered as that channel being active.

The signal monitor portion of the monitor is also capable of checking for the absence of any required signal voltage

on each channel at the field connection terminals in the Controller Assembly. For this purpose a signal on the

Green, Yellow, Walk, or Red/Don’t Walk inputs associated with a channel shall be considered as that channel

being active.

The voltage monitor portion of the monitor is capable of checking the Controller Unit Voltage Monitor output that

indicates satisfactory operating voltage in the Controller Unit and the +24 volt direct current inputs.

The Model MMU2-1600G is fully programmable. The monitor has a unique graphics based Organic Light

Emitting Diode (OLED) display. The OLED display allows access to all configuration settings, real-time monitor

status with applicable AC and DC voltages, advanced diagnostic information, all logs including the most current

signal sequence log, and context sensitive help screens.

An interchangeable programming card is provided to allow the assignment of permissive or compatible channels.

Programming is accomplished through the use of soldered wire jumpers on the programming card. The

programming card may be used in a monitor operating in either Type 16 or Type 12 mode. The programming card

can be inserted into the monitor through a slot in the front panel. The programming card also contains a serial

EEPROM. This device is used to store programming information not set by the wire jumpers. Features stored in

the serial EEPROM include Flashing Don’t Walk Monitoring, Co-Channel Childs, Per Channel Red Enable,

Location, Unit ID, Agency ID, IP Address, and others.

When configured in the Type 16 mode and connected to a TS 2 Controller Unit, the monitor has the ability to

exchange information in a standardized format with the Controller Unit in real time through the Port 1 interface.

The monitor and the Controller Unit perform redundant checks on each other through messages defined in the TS 2

Standard. The Controller Unit can access monitor information including field signal input status, permissive

programming, and fault status. This gives the Controller Unit the capability to function as a backup monitor and

make enhanced event logging, remote intersection monitoring, and remote diagnostics possible. Likewise, the

monitor receives information from the Controller Unit corresponding to Controller Unit output commands to the