PIKUS 105/105DL – PIKUS 75/75DL ENGLISH

6

Noise

The machine noise output is measured on production samples in compliance with ISO 3754-77 and ISO CD

11201-91.

PIKUS 105/105DL PIKUS 75/75DL

Lw 103,5 [dBw(A)] 10,2[mW(A)] 103,5 [dBw(A)] 10,2[mW(A)]

Lop 101,0 [dB(A)] 111,5 [mW(A)] 101,0 [dB(A)] 111,5 [mW(A)]

Safety Precautions

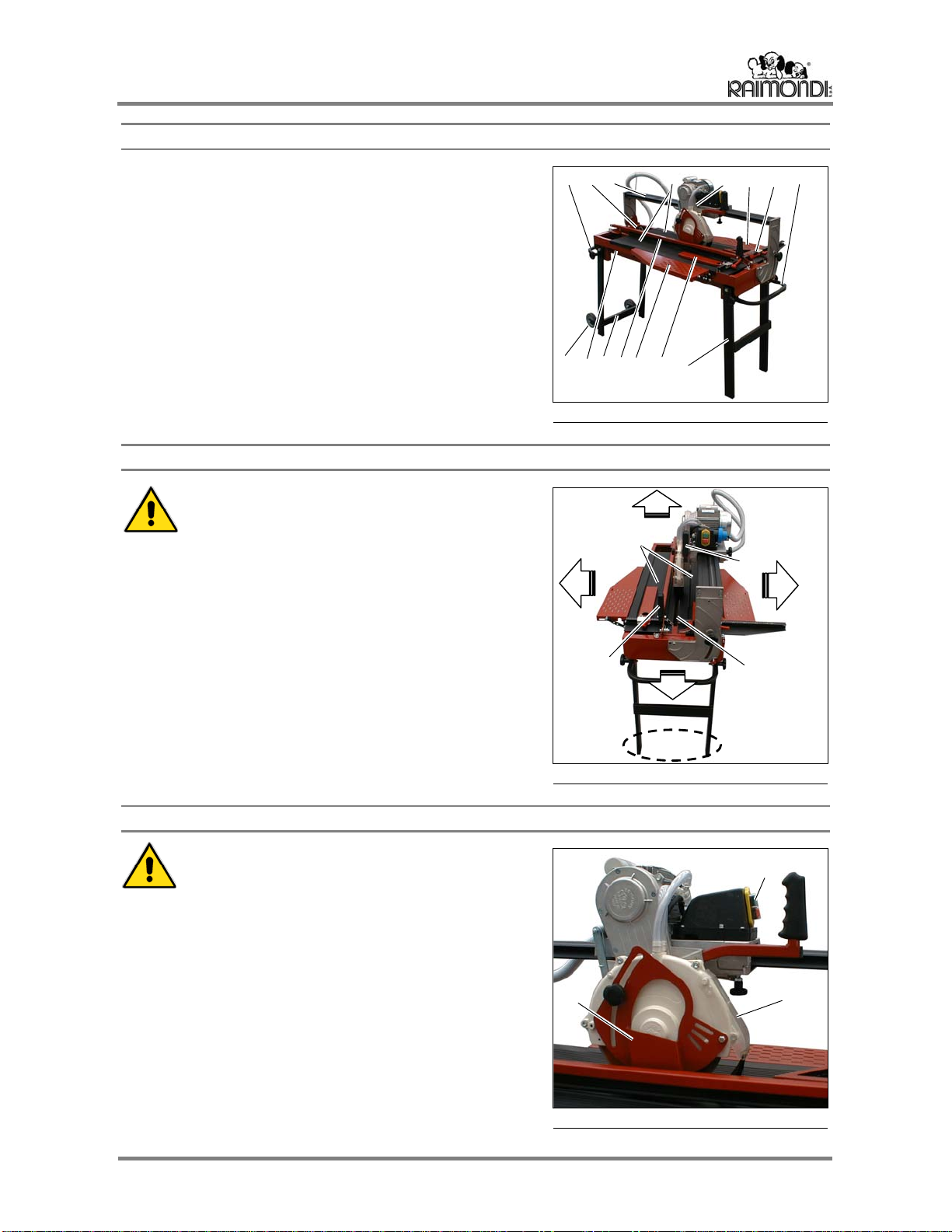

Before starting any type of cutting operation, always check:

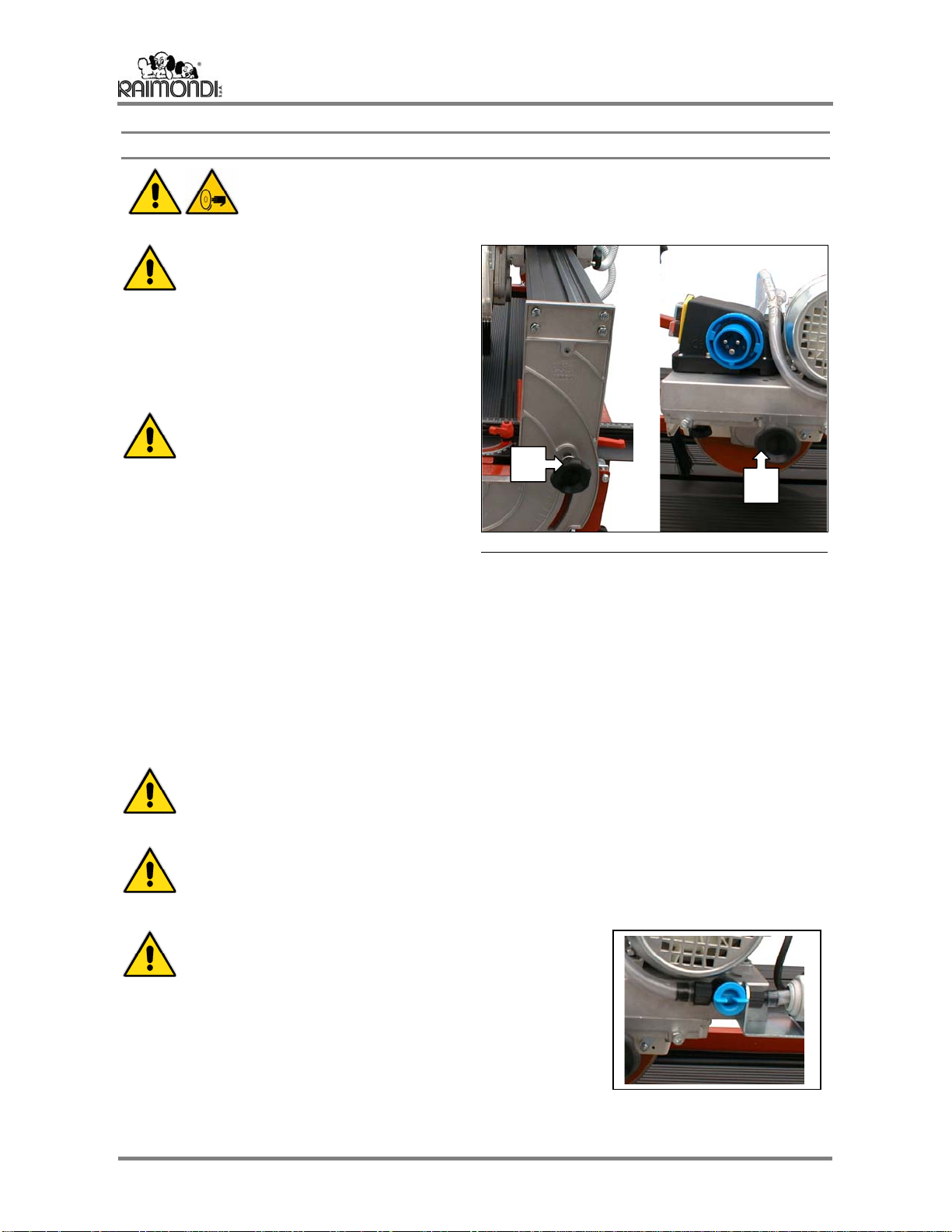

the level of cooling water (the pump must be entirely submersed);

ATTENTION:

•that the disk guard has been positioned correctly;

•that the disk is sharp; if necessary run it with the sharpening stone;

•that the disk shows no signs of cracking; if necessary, replace;

•that nobody is in the work area except those directly involved in the operations.

The paragraph on NOISE indicates the level of noise emitted by the machine during operation.

If the machine is operated by a single operator for an entire eight-hour shift, the person may be

exposed to a daily noise level of more than 85 dB(A).

To reduce the risk stemming from exposure, use appropriate ear protection.

Also see Italian Law 277/91 for more specific indications.

Always wear goggles and protective gloves.

If the machine cuts out unexpectedly, it means that the motor overload cutout has kicked in.

In this case, unplug the machine from the power supply and wait until the motor and overload

cutout have cooled down.

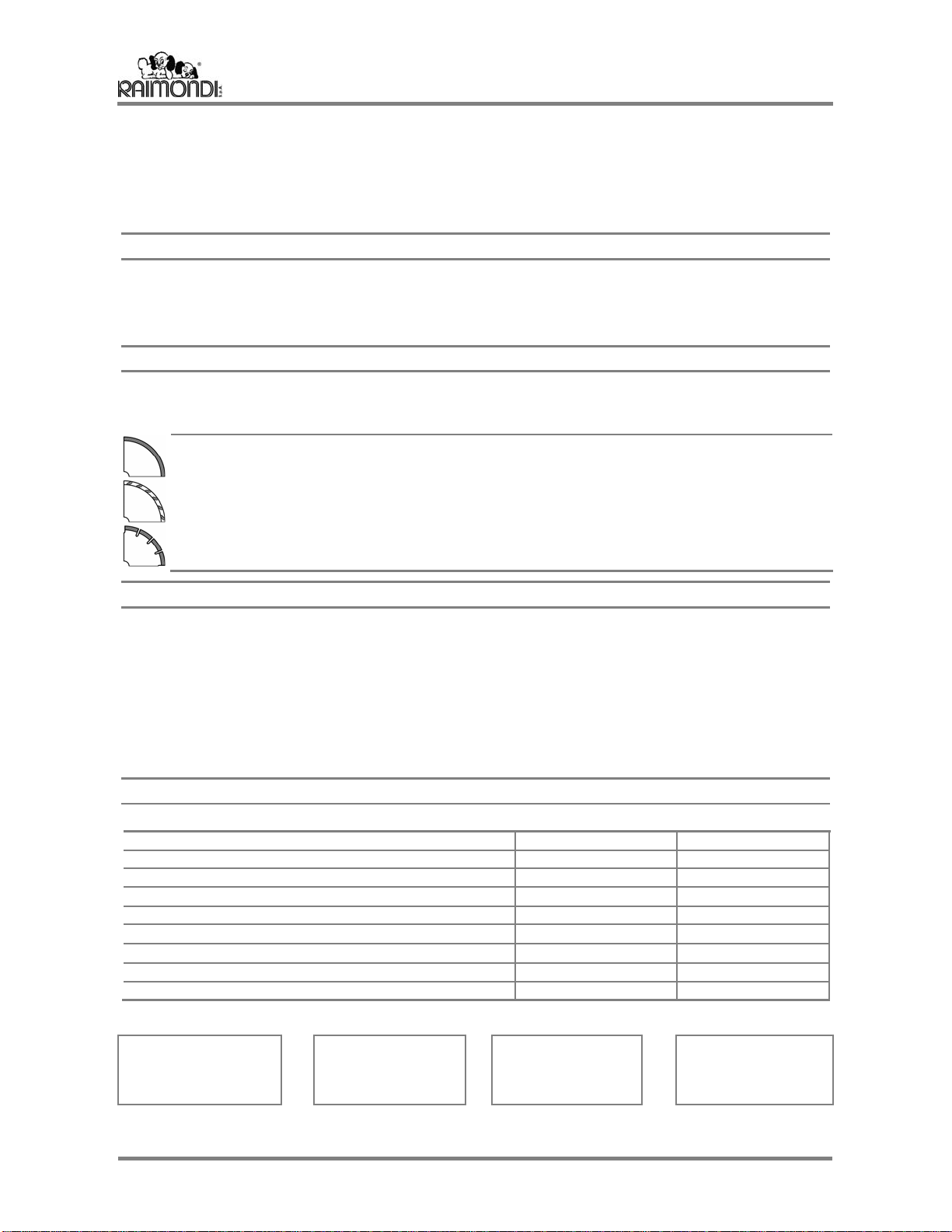

Transport of the package

Handle by means of a forklift truck, inserting the forks in the

appropriate openings at the bottom of the pallet. Use a forklift truck

of a suitable load-carrying capacity (>200 kg).

Manual handling

•Drain any water in the tank.

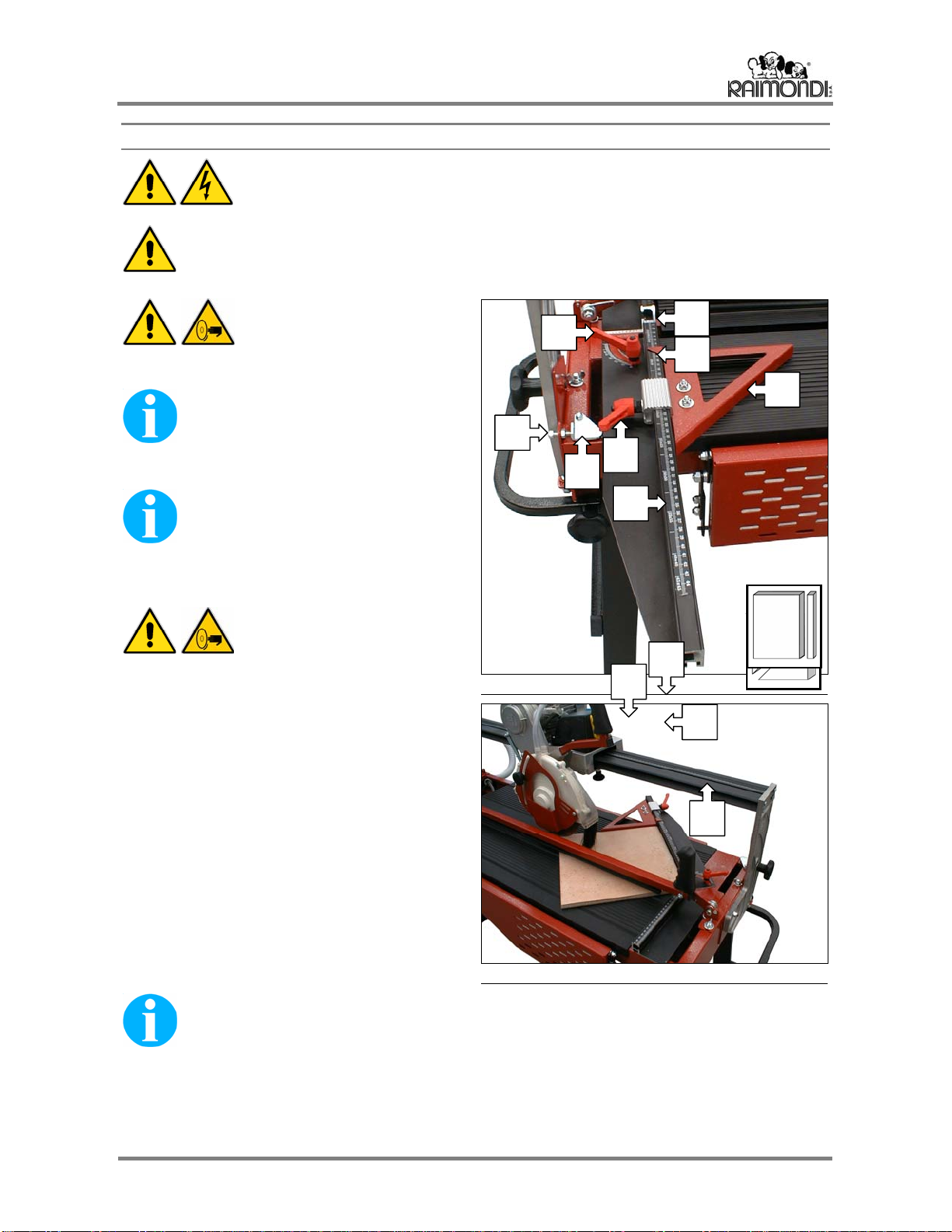

•Loosen the knob under the motor assembly, move the latter to the centre of the slide bar and tighten the

knob again, to balance weight.

•Fold the machine’s legs (the front leg first) and secure the latter in place with the knobs provided.

•Before transporting the machine, lift the front and rear sides of the machine.

TWO PEOPLE ARE REQUIRED TO MOVE AND INSTALL THE MACHINE.

TO TRANSPORT THE MACHINE OVER SMALL SPACES, LIFT IT USING THE FRONT HAN-

DLE AND PULL IT FORWARDS WITH THE AID OF THE REAR WHEELS.

FIG.4