2

READ ALL INSTRUCTIONS THOROUGHLY FROM START TO FINISH BEFORE BEGINNING INSTALLATION

IMPORTANT NOTES!

WARNING: This suspension system will enhance the off-

road performance of your vehicle. It will handle differently,

both on and off-road, from a factory equipped passenger car

or truck. Extreme care must be used to prevent loss of

control or vehicle rollover during abrupt maneuvers. Failure

to drive this vehicle safely may result in serious injury or

death to the driver and passengers. ALWAYS WEAR your

seat belts, REDUCE your speed, and AVOID sharp turns

and other abrupt maneuvers.

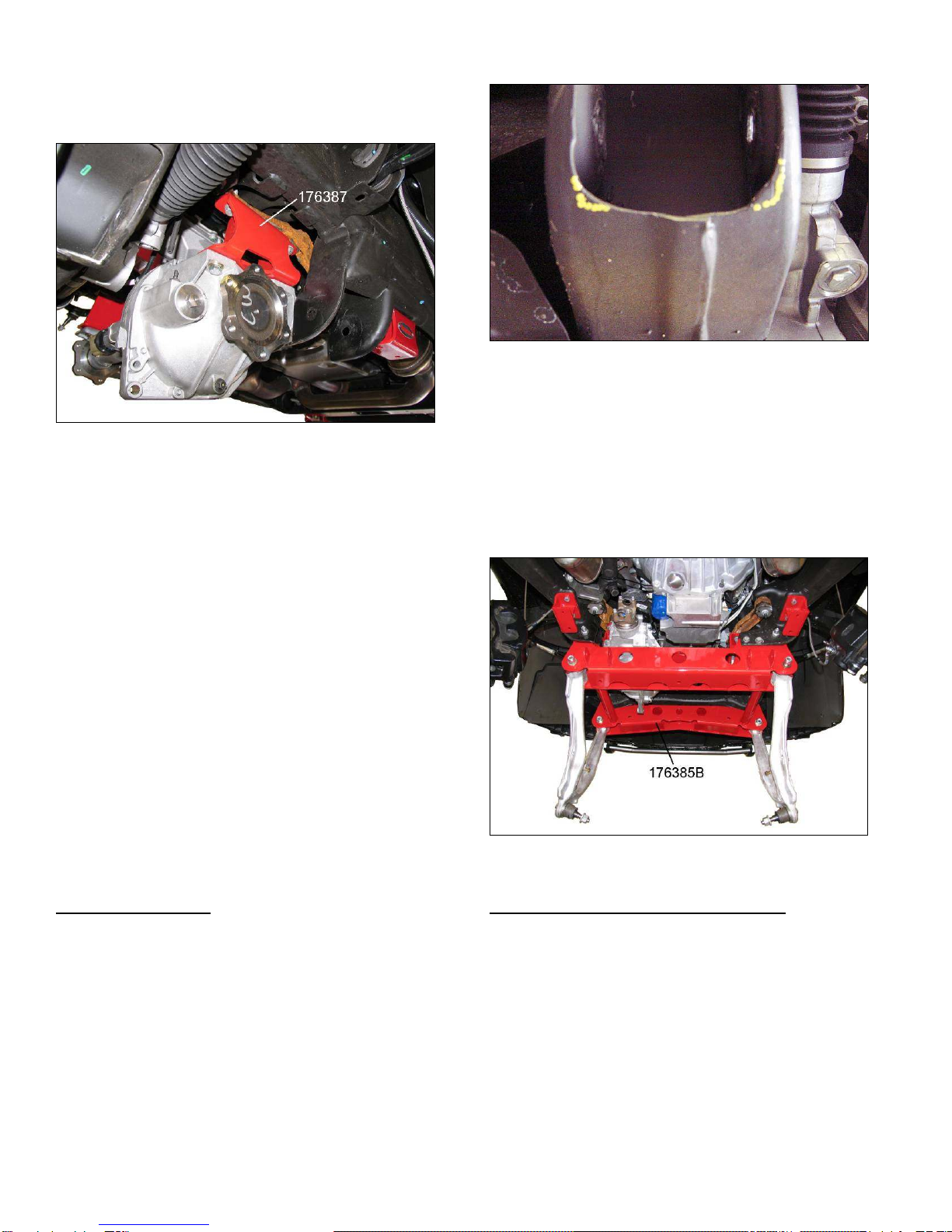

A. To reduce front drive shaft vibration, a replacement

shaft (part No. 3194-9824) is available from: POWERTRAIN

INDUSTRIES 7532 Anthony Avenue, Garden Grove, CA

92841 1-800 798-4585. For vehicles equipped with the

Autoride (Air) Suspension Option, front shock RS99799

and rear relocator kit RS6202 must be installed.

B. Before installing this system, have the vehicle’s

alignment and frame checked by a certified technician. The

alignment must be within factory specifications and the

frame of the vehicle must be sound (no cracks, damage or

corrosion).

C. Do not install a body lift kit with this suspension system

or interchange Rancho components with parts from another

manufacturer. New Rancho shock absorbers are required

and must be purchased separately. Front shocks:

RS999786 or RS999799, Rear shocks: RS999297

D. Do not powdercoat, chrome, cadmium, or zinc plate any

of the components in this system. To change the

appearance of components, enamel paint can be applied

over the original coating.

E. Welding on a car creates an electrical charge

throughout the body and frame. Disconnect the vehicle’s

battery prior to any welding. Place welding ground clamps

as near as possible to the weld. When welding on the

frame, never use a vehicle suspension component as a

welding ground point.

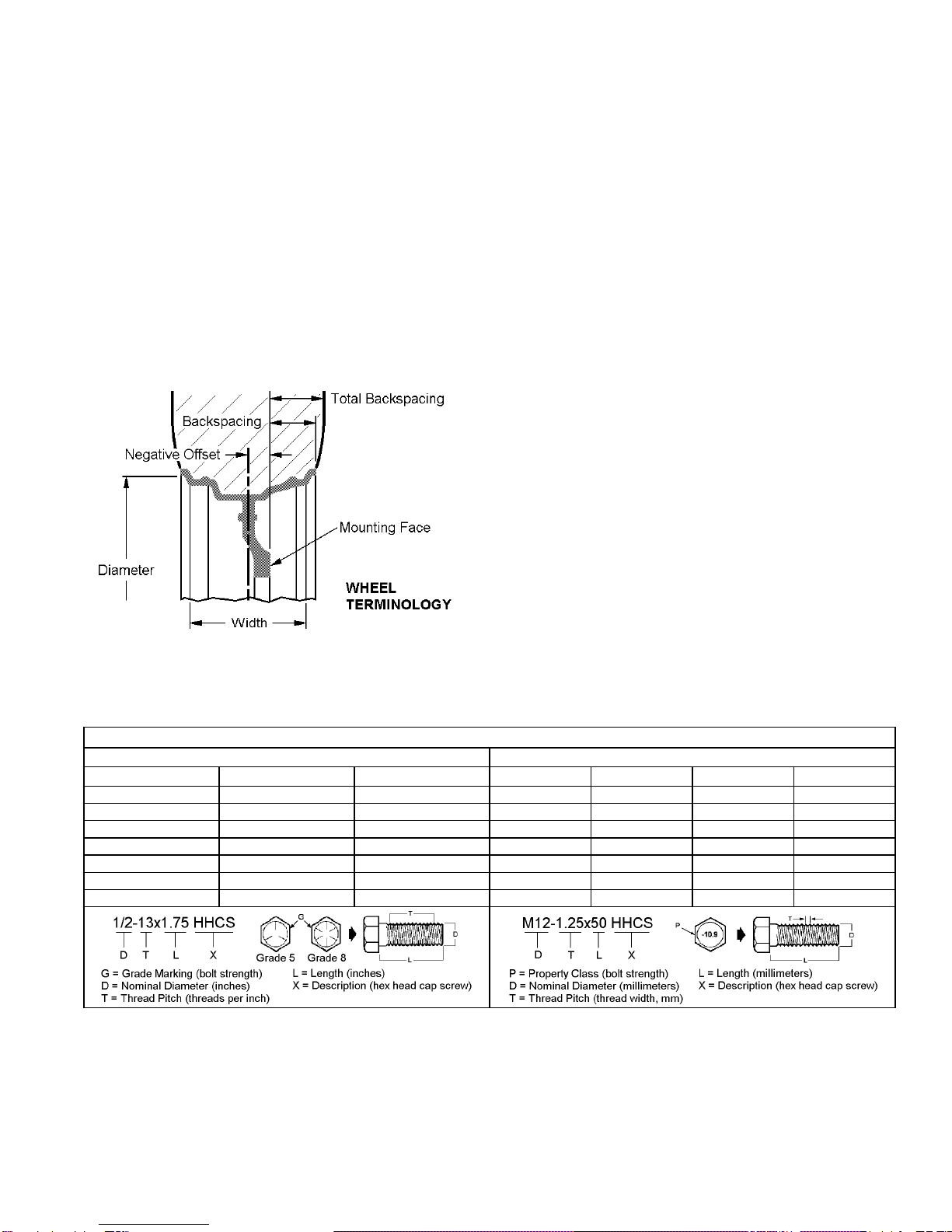

F. Each hardware kit in this system contains fasteners of

high strength and specific size. Do not mix hardware kits or

substitute a fastener of lesser strength. See bolt

identification table on page 2.

G. Compare the contents of this system with the parts list

in these instructions. If any parts are missing, contact the

Rancho Technical Department at 1-734-384-7804.

H. Install all nuts and bolts with a flat washer. When both

SAE (small OD) and USS (large OD) washers are used in a

fastener assembly, place the USS washer against the

slotted hole and the SAE washer against the round hole.

I. Apply a drop of thread locking compound to all bolts

during installation. CAUTION: Thread locking compound

may irritate sensitive skin. Read warning label on container

before use.

J. Unless otherwise specified, tighten all nuts and bolts to

the standard torque specifications shown in the table below.

USE A TORQUE WRENCH for accurate measurements.

K. Some of the service procedures require the use of

special tools designed for specific procedures. The following

tools and supplies are recommended for proper installation

of this system:

Chevrolet Service Manual

Coil Spring Compressor

Die Grinder

Drill motor

Assorted Drills: 1/8" through 1/2"

Torque Wrench (250 FT-LB capacity)

1/2” Drive Ratchet and Sockets

Assorted Combination Wrenches

Heavy Duty Jack Stands

Wheel Chocks (wooden blocks)

Hydraulic Floor Jack

Center punch

File

Reciprocating Saw (to modify frame)

Hammer

Wire Brush (to clean bracket mounting surfaces)

Silicone Spray Lubricant

Brake fluid

Tape Measure

Safety Glasses (wear safety glasses at all times)

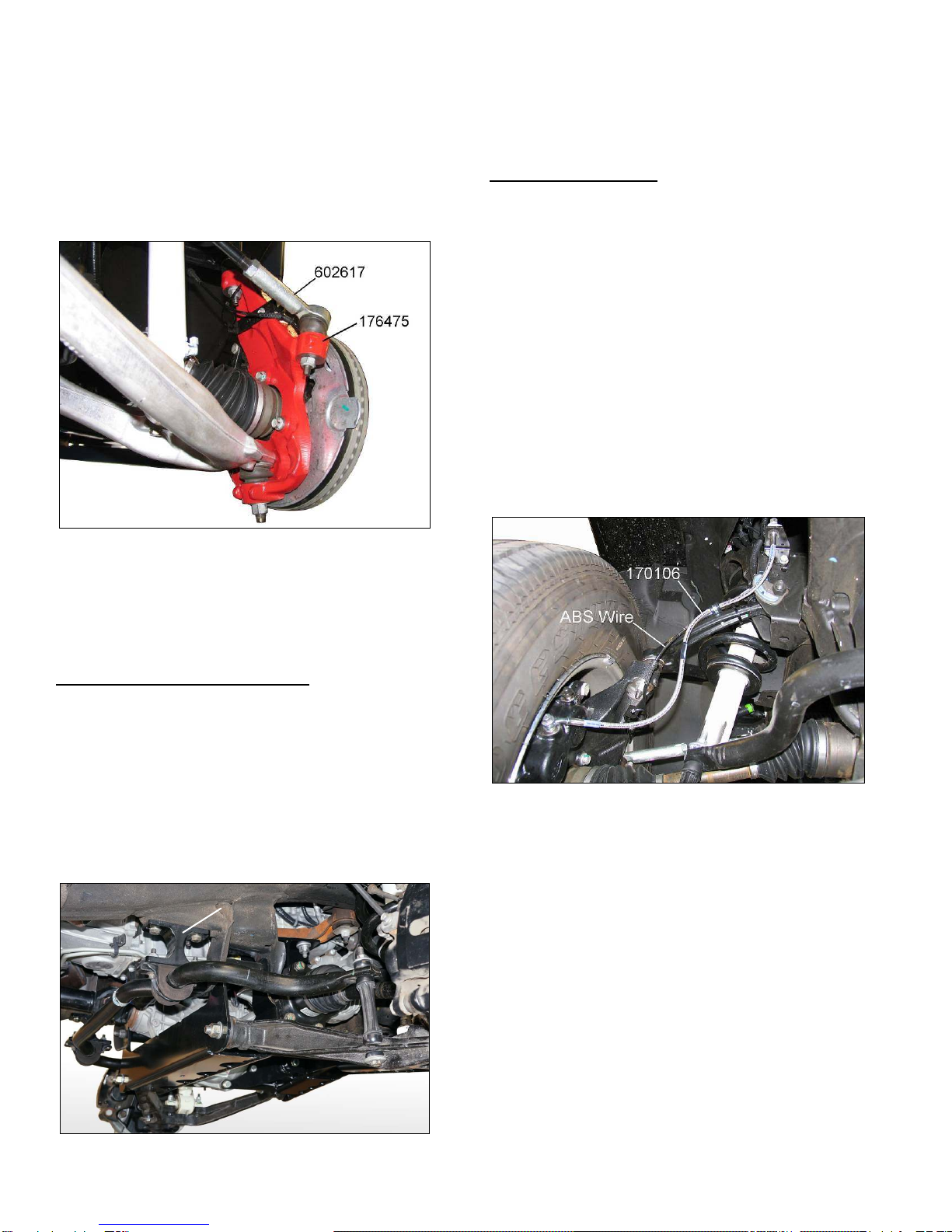

L. It is extremely important to replace torsion bars, CV

flanges, and front drive shaft/pinion relationships as original.

Be sure to mark left/right, front/rear, and indexing of mating

parts before disassembly. A paint marker or light colored

nail polish is handy for this.

M. Suspension components that use rubber or urethane

bushings should be tightened with the vehicle at normal ride

height. This will prevent premature failure of the bushing

and maintain ride comfort.