3

1. OVERVIEW

This model has an ergonomic design and is manufactured using numerically - controlled

machine tools. It is recommended for use in hospitals, medical schools, scientific research institutes,

and food quarantine and inspection organizations.

With its novel design, this instrument has a high precision, stable performance, and easy

operation. It possesses the following features:

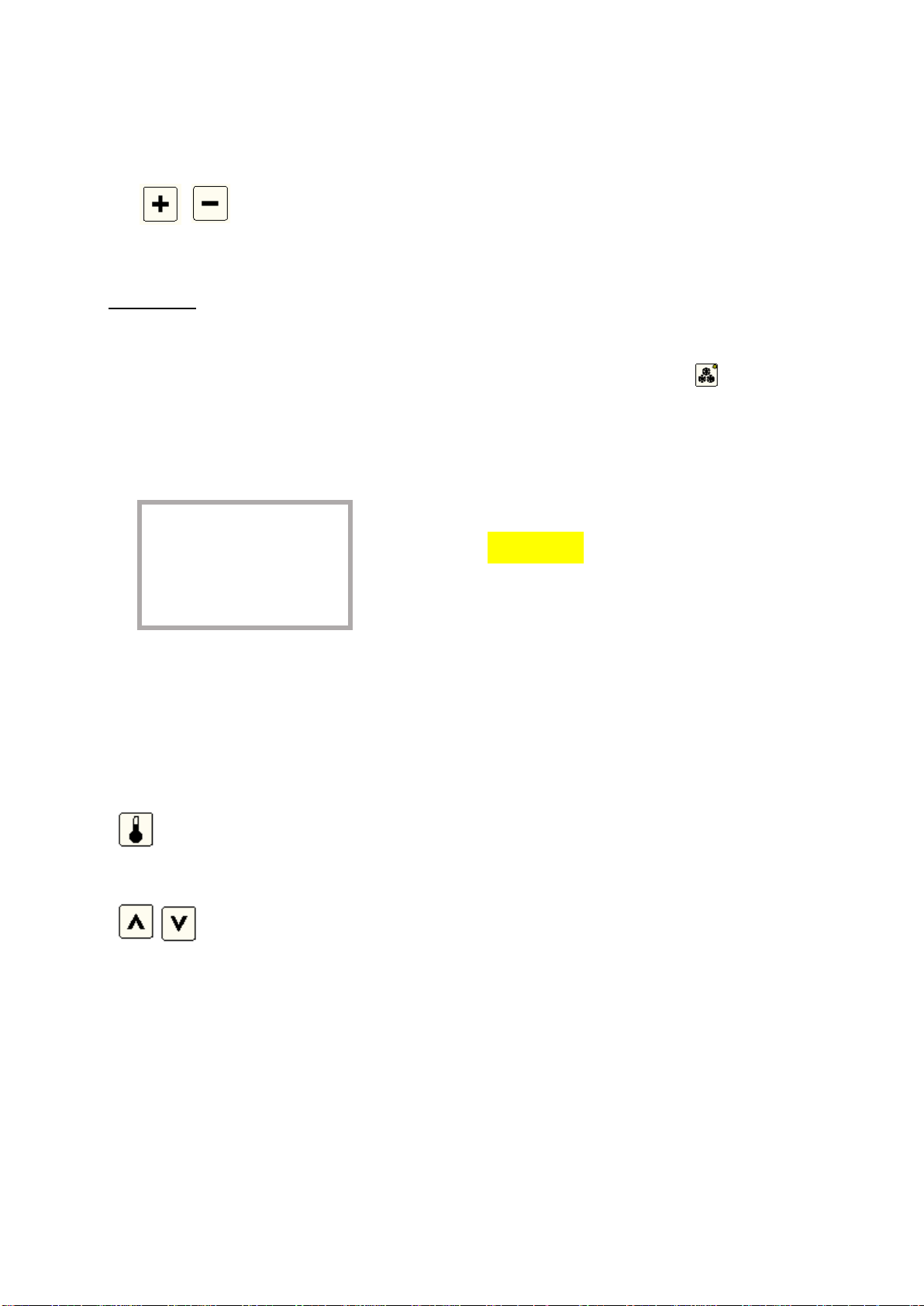

▪A specimen retraction function protects the specimen from blade damage.

▪A trim button allows for easy switching between trim and sectioning mode.

▪It has a counting function for the number of sections and the total thickness.

▪The cryogenic refrigeration system utilizes a forced cooling structure. The refrigeration

chamber, freezing shelf, blade holder, and specimen holder are cooled independently by a

German double compressor to enhance cooling performance and increase cooling speed.

▪Imported R404A non-CFC refrigerants that are environment-friendly.

▪It achieves the desirable sectioning temperature within 60 minutes after turning on the unit

when using the specimen head cooling.

▪UV option enables surface disinfection of harmful bacteria, viruses, and spores by using 35

min after each use.

▪The Peltier semiconductor cooling function on the quick freeze shelf can be turned on and off.

▪Heated and removable glass door.

▪Two defrosting modes: programmed defrosting and manual defrosting.

▪Microtome is outside of the refrigeration chamber to avoid the effect of heat-expansion and

cold-contraction, thus minimizing the need for maintenance.

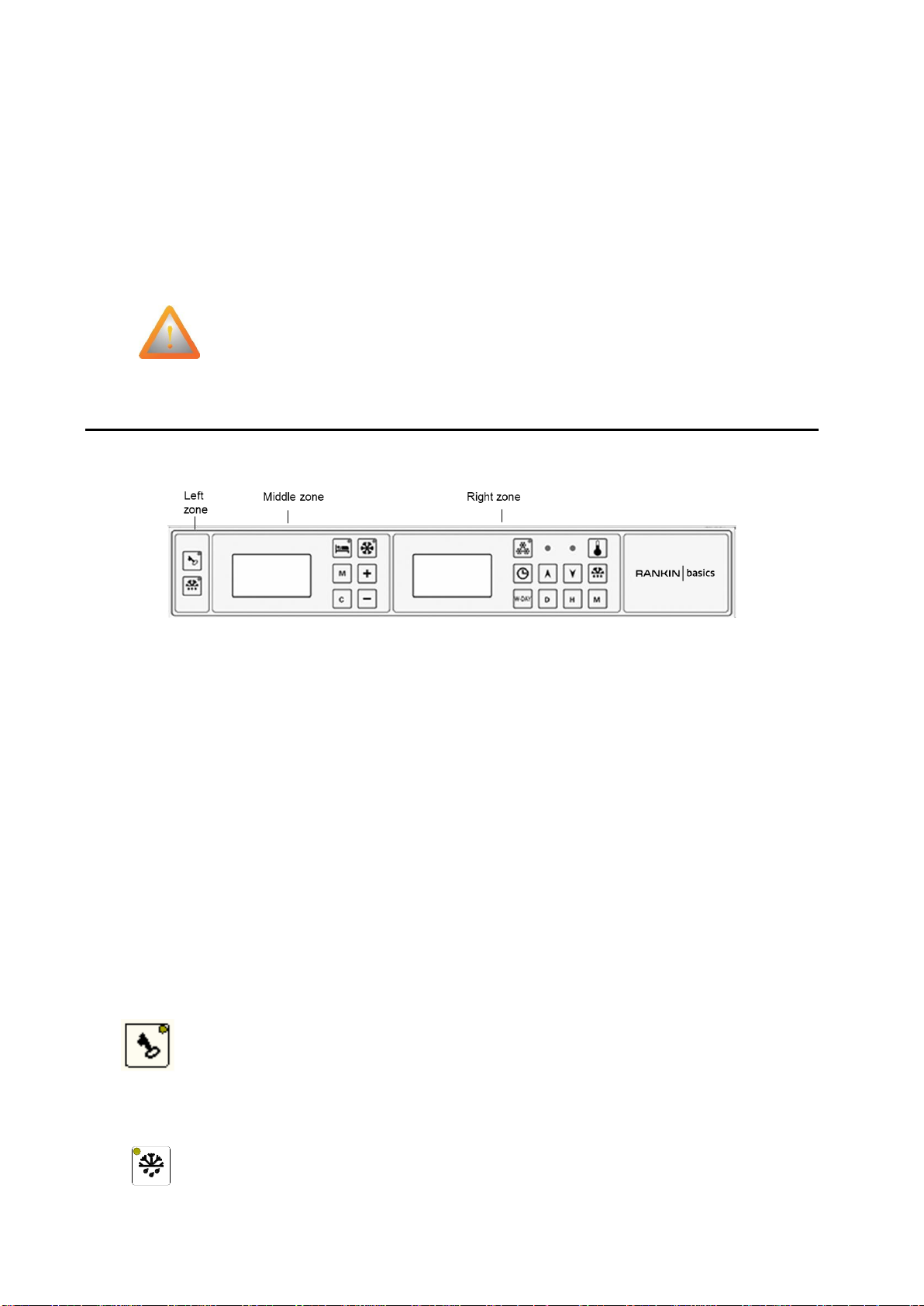

▪User-friendly intelligent operational interface is easy to learn and operate.

▪LCD screen displays the number of sections and the total thickness, section thickness,

specimen retraction value, temperature setting, date, time, temperature, and on/off timer are

all included on the main display.

▪Auto sleep function results in longer compressor life: the cryochamber temperature

automatically stays in a range of -4 to -9℃under the sleep mode, and returns to the sectioning

temperature within 10 minutes after canceling the sleep mode.

▪Keyboard locking function to avoid accident mis-operation.

▪A mechanical handwheel lock ensure safe chamber access.

▪A large quick-freezing shelf allows for the preparation of 26 specimens at the same time, two

of which are cooled by a Peltier semiconductor.