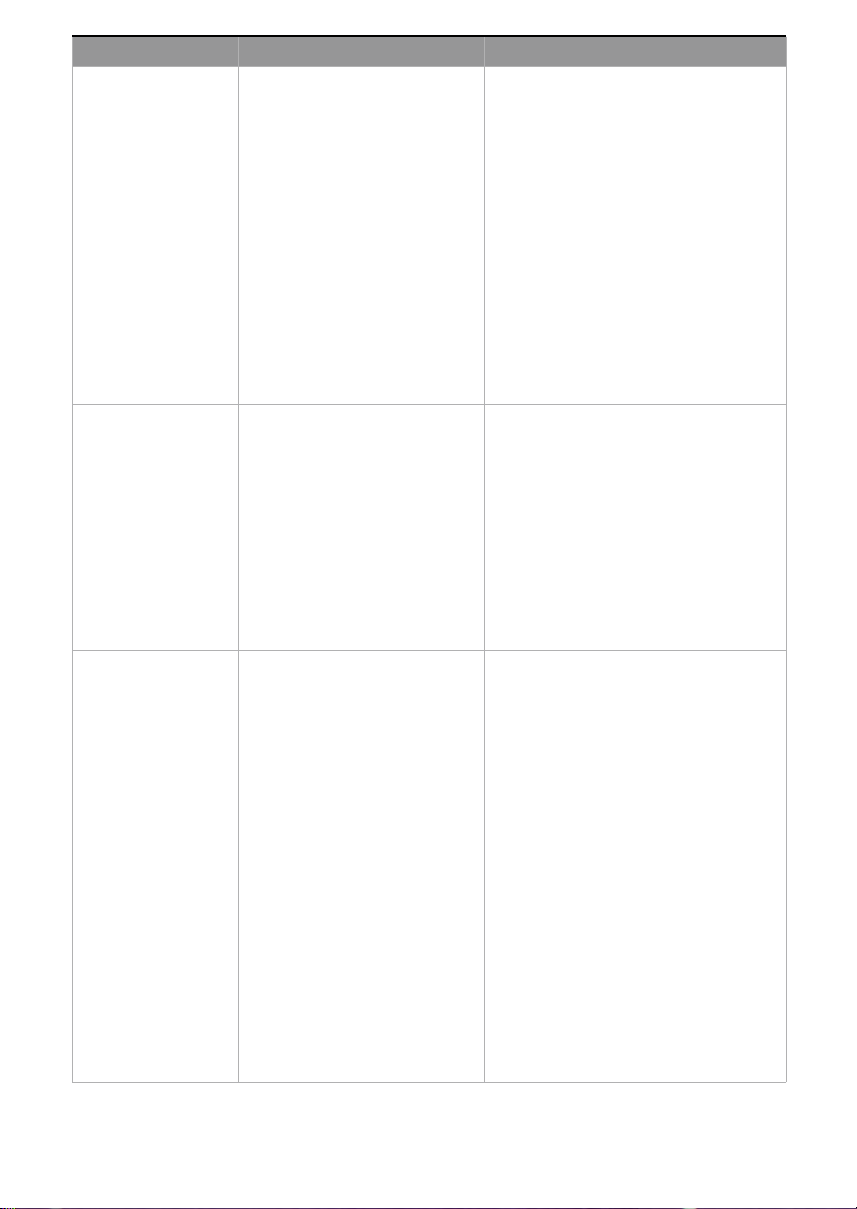

6

The lower pot

cover does not

descend properly.

1. The lower pot cover

motor is not installed

correctly.

2. The lower pot cover

motor is faulty.

3. The mainboard is faulty.

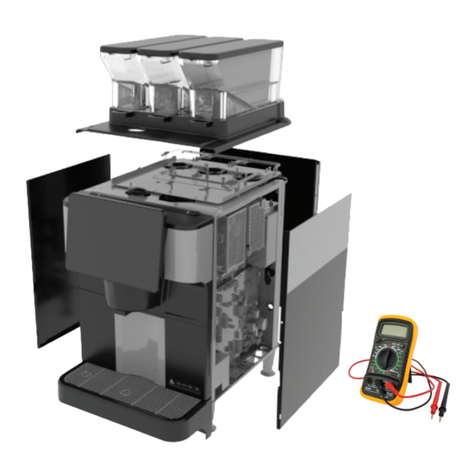

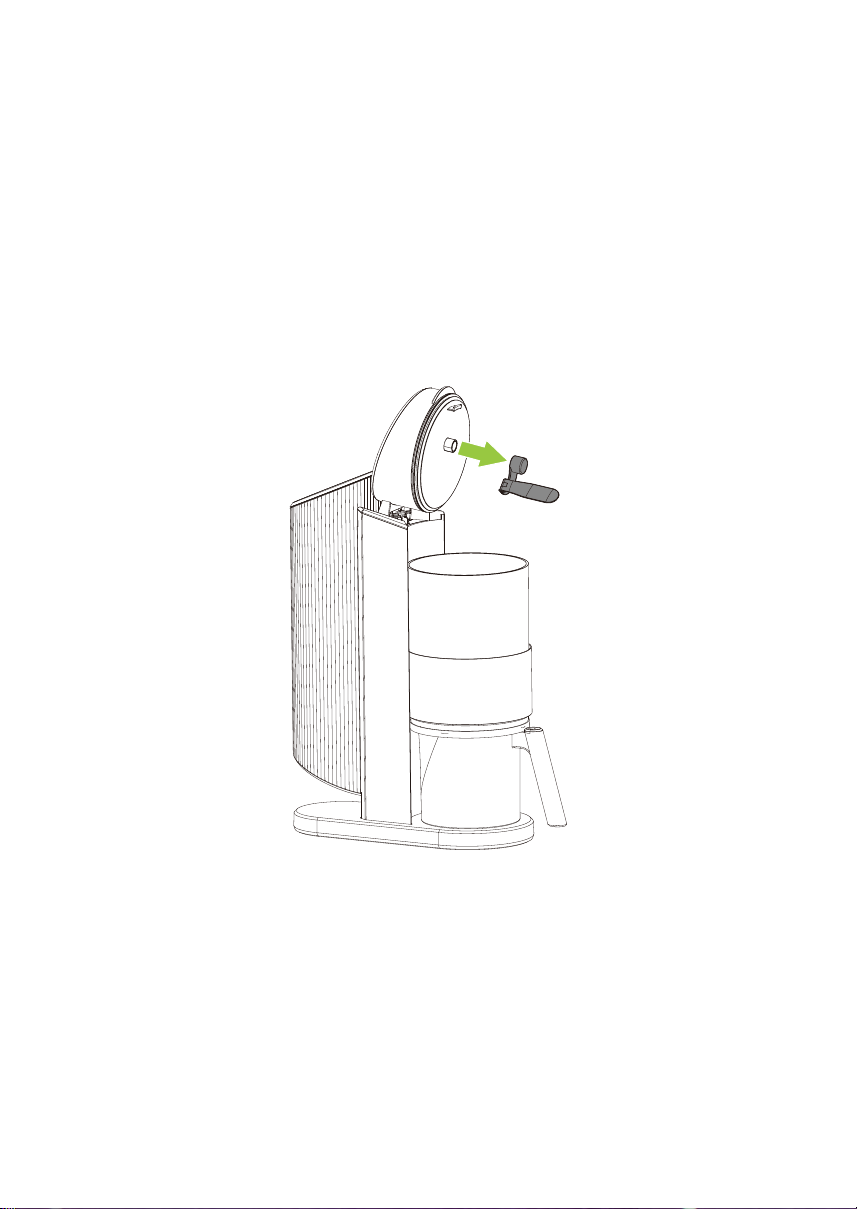

1. Ensure that the lower pot cover

motor is secured properly. See

“Securing the Lower Pot Cover

Motor” on page 35 for

instructions.

2. Replace the lower pot cover

motor. See “Replacing the

Lower Pot Cover Motor” on

page 31 for instructions.

3. Replace the mainboard. See

“Replacing the Mainboard” on

page 18 for instructions.

When the pump is

supposed to be

operating, it does

not fluctuate

between a hight

and low frequency

so it does not

sound like there is

any suction

occurring.

1. The lower pot has not

been properly pressure

sealed.

2. The lower pot cover

motor is faulty.

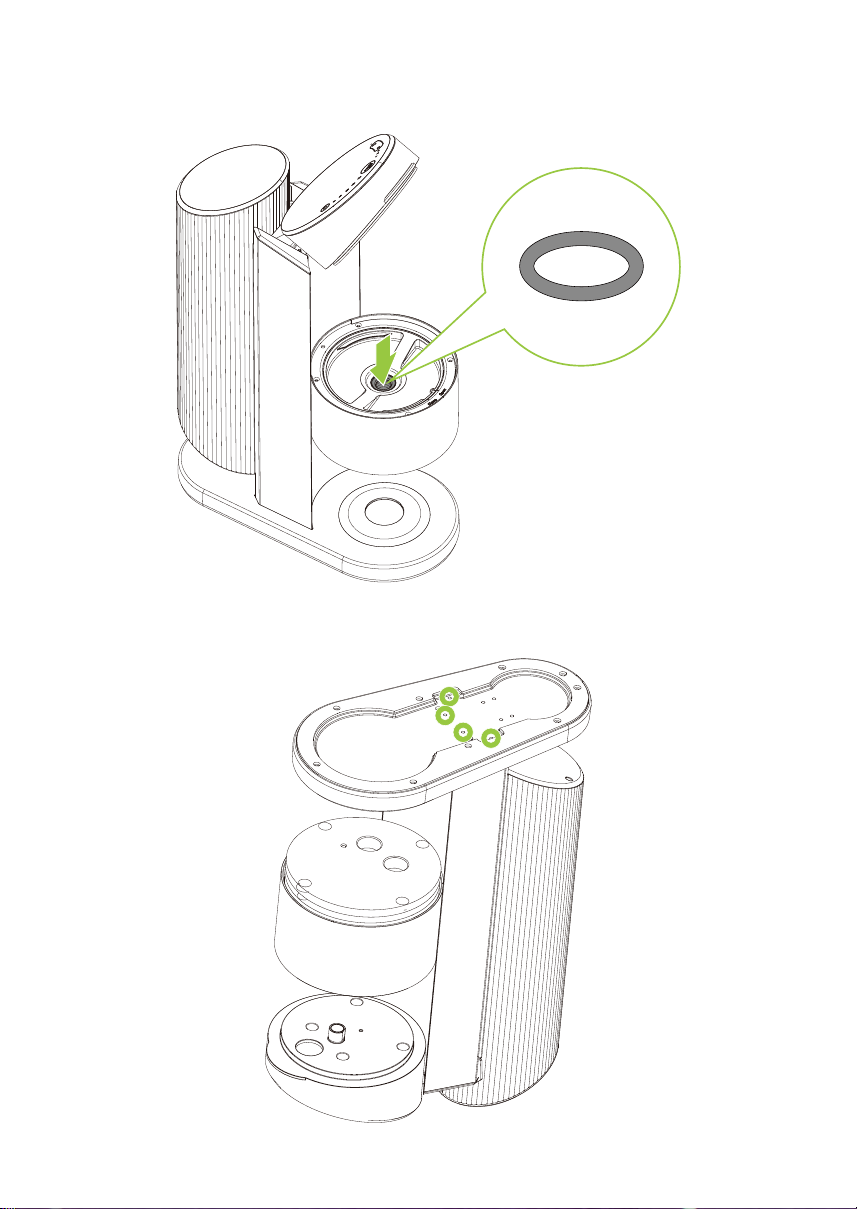

1. Correct the lower pot cover

pressure. See “Correcting the

Lower Pot Cover Pressure” on

page 33 for instructions.

2. Replace the lower pot cover

motor. See “Replacing the

Lower Pot Cover Motor” on

page 31 for instructions.

The stirrer is not

rotating.

1. Plastic rotary head is

faulty.

2. The stirrer motor is not

installed correctly.

3. The 6-pin stirrer motor

cable is faulty.

4. The mainboard is faulty.

1. Replace the plastic rotary head.

See “Replacing the Plastic

Rotary Head” on page 47 for

instructions.

2. Ensure that the stirrer motor is

secured properly. See “Securing

the Stirrer Motor” on page 46

for instructions.

3. Replace the 6-pin stirrer motor

cable. See “Replacing the 6-Pin

Stirrer Motor Cable” on

page 51 for instructions.

4. Replace the mainboard. See

“Replacing the Mainboard” on

page 18 for instructions.

Issue Possible Cause Suggested Solution