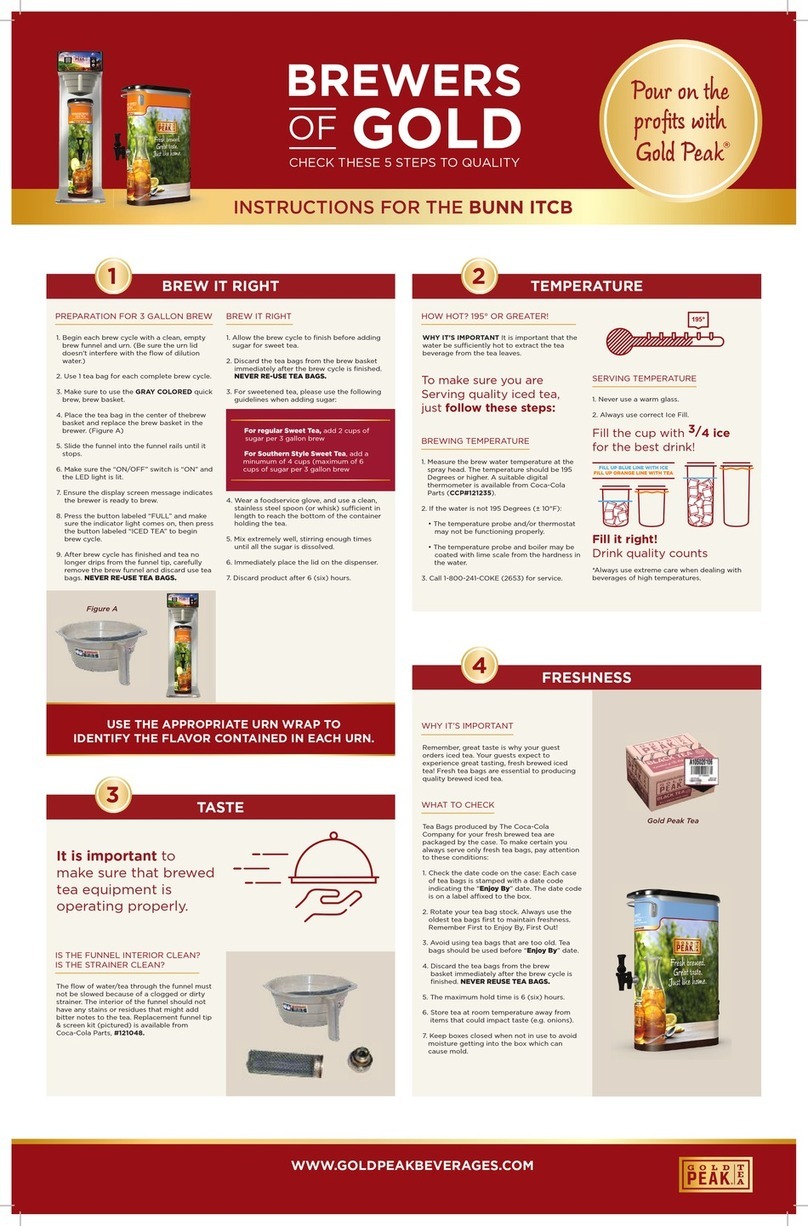

Cleanliness

Freshness

First to Enjoy By...First Out!

WHY IT’S IMPORTANT

Remember, great taste is why your

customer orders iced tea. Your

customers expect to experience

great tasting, fresh brewed iced

tea! Fresh tea bags are essential to

producing quality brewed iced tea.

WHAT TO CHECK

Tea Bags produced by The Coca-Cola

Company for your fresh brewed tea are

packaged by the case. To make certain

you always serve only fresh tea bags,

pay attention to these conditions:

1. Check the date code on the case:

Each case of tea bags is stamped

with a date code indicating the

“Enjoy By” date. The date code is

on a label affixed to the box.

2. Rotate your tea bag stock. Always

use the oldest tea bags first to

maintain freshness. Remember

First to Enjoy By… First Out!

3. Avoid using tea bags that are too

old. Tea bags should be used before

“Enjoy By” date. The shelf life for

each product from the date of each

manufacturer is:

Gold Peak Black Tea = 18 months

4. Discard the tea bags from the

brew basket immediately after the

brew cycle is finished. NEVER RE-

USE TEA BAGS.

5. The maximum hold time is 6 (six)

hours. To help ensure the tea you

serve is always fresh, a brew date

sticker is available via the Coke

Catalog for use with your dispenser

urns. Place the sticker on the side

of the urn and simply write in the

date and time the tea was placed

in the urn. Contact

your Coca-Cola Sales

representative should

you want these stickers.

6. Store tea at room temperature

away from items that could

impact taste (e.g. onions).

7. Keep boxes closed when not

in use to avoid moisture getting

into the box which can cause

mold.

Brew date sticker

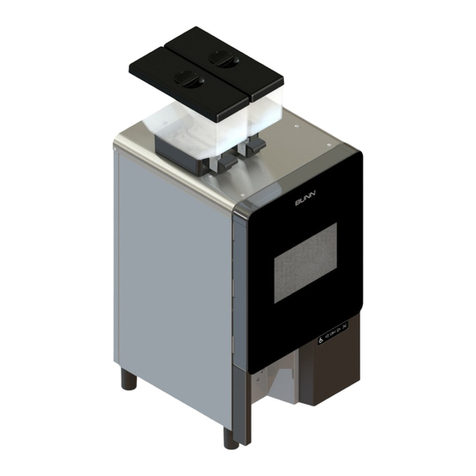

SLIMLINE URN DAILY CLEANING INSTRUCTIONS

1 Once a day, turn the faucet in a

counterclockwise direction and

remove the faucet from the dis-

penser. Unscrew the faucet cap

from the faucet body and disas-

semble all faucet parts.

2 Transfer these parts to a three

compartment sink for cleaning. Fill

the first sink with a soap solution

using a mild detergent, the second

sink is used for clean rinse, and the

third sink with a sanitizer solution

(75°F warm chlorine solution of at

least 50-100 ppm).

3 Use a bristle brush (CCP #18616/

BUNN #00674.0000) to thoroughly

scrub the faucet body.

4 Allow the parts to soak in a

sanitizer solution for a minimum of

ten minutes.

5 Remove the faucet parts from

the sanitizer solution and rinse

thoroughly. Allow parts to air dry

over night.

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY

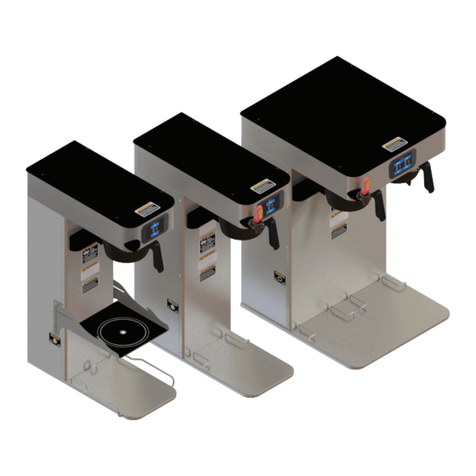

Brew cycle will not start No water or no power • Make sure the water lines and

valves are open

• Make sure the brewer is plugged

in, or check the circuit breaker

• Make sure the ON/OFF switch is working

• Could be front enable/on-off switch

Weak or bitter tasting beverage Missing sprayhead or brew funnel tip • Replace sprayhead or brew funnel

Dirty sprayhead or brew basket • Clean and sanitize the sprayhead and

brew basket

Dirty dispenser faucet • If dirty dispenser faucet: disassemble,

clean and sanitize the dispenser faucet

Your customers

associate a

clean, tidy area

with quality.

WHY IT’S IMPORTANT

Keeping your dispensing system clean

helps keep it operating properly. A clean,

sanitary appearance communicates quality

to your customers.

WHAT TO DO

It’s easy to keep your dispensing area clean

and orderly when you follow this regular

schedule of activities.

BREWER

CLEANING INSTRUCTIONS

1. Place the ON/OFF switch in the “OFF” position.

2. Wipe the exterior of the machine daily.

3. Remove the sprayhead daily.

• Wash in hot water and dish detergent, rinse, sanitize,

and air-dry.

• Ensure sprayhead holes are not blocked.

• Wipe the sprayhead area of the brewer.

4. Thoroughly clean the brew basket after each use.

• The funnel tip and screen must be free of any tea

particles or residue.

• Wash with dish detergent, rinse, sanitize, and air-dry.

WEEKLY CLEANING

1 Once a week, fill the dispenser

with a chlorine solution (75°F

warm chlorine solution of at least

50-100 ppm).

2 Draw a small amount (2 oz.) of

presoak through the faucet mak-

ing contact with the faucet compo-

nents. Allow the dispenser to soak

over night. The next morning, per-

form the daily cleaning procedures

on the faucet and dispenser.

6 Thoroughly clean the entire

inside surface of the dispenser

using a large plastic bristle brush

(CCP #28884) and the faucet shank

using a small brush, (CCP #18616/

BUNN #00674.0000) mild detergent

and water solution. Thoroughly

rinse the dispenser with clean water.

7 Using a clean plastic pail, pre-

pare 2.5 gallons 100 ppm sanitizing

solution in lukewarm water (85

– 105° F), using 1 pack of Kay-5™

sanitizer (CCP #25823). Make sure

all of the Kay-5™ crystals have dis-

solved completely.

8 Pour a small amount of sanitizer

solution into the dispenser. Use a

bristle brush, (CCP #18616/BUNN

#00674.0000) to clean all the way

through the faucet shank. Repeat

3 times.

9 Thoroughly rinse the dispenser

with clean water. Allow the dis-

penser to air dry over night

10 Assemble the faucet compo-

nents and attach the faucet to the

dispenser turning clockwise.

6 MONTH CLEANING

1 It is recommended to replace the

faucet seat cup every 6 months (CCP

#118348/BUNN #00600.0000).

2 Discard the old seat cup and

reassemble. Alternatively, the

faucet Assembly, (CCP #122334/

BUNN #03260.0003), can be

ordered for replacement.