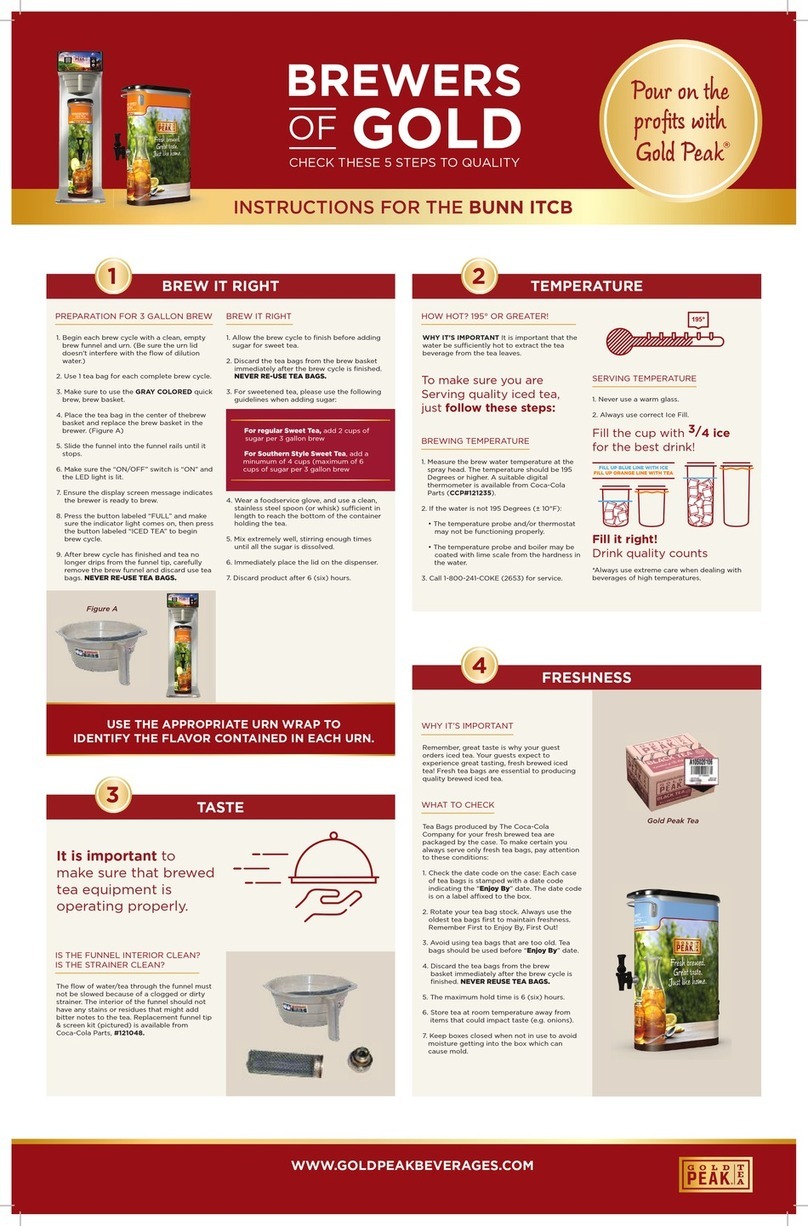

BREWERS

OF GOLD

Check These 5Steps to Quality

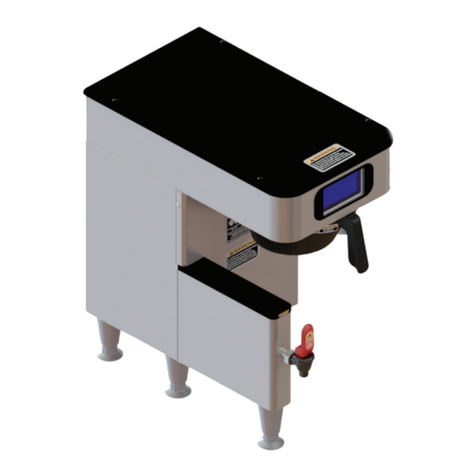

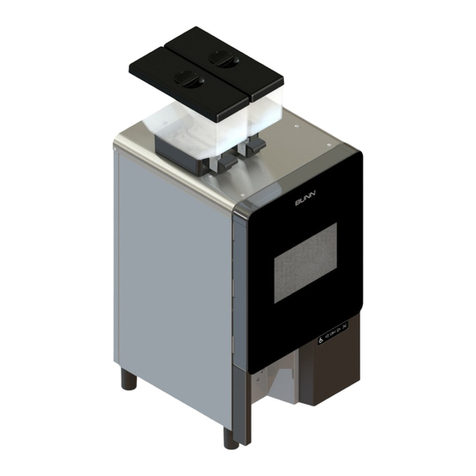

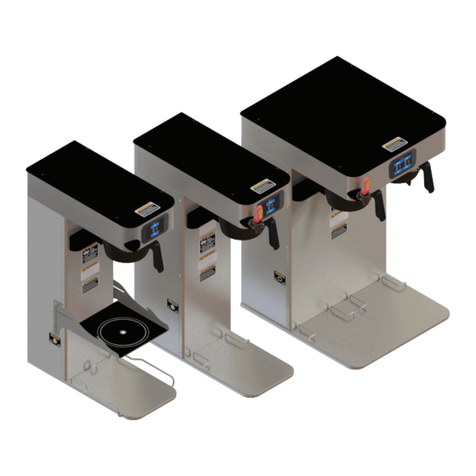

BREWING INSTRUCTIONS

FOR THE BUNN ITCB/MIS

HOW HOT?

195 Degrees (+_ 10°)

or Greater!*

WHY IT’S IMPORTANT

It is important that the water be

sufficiently hot to extract the tea

beverage from the tea leaves.

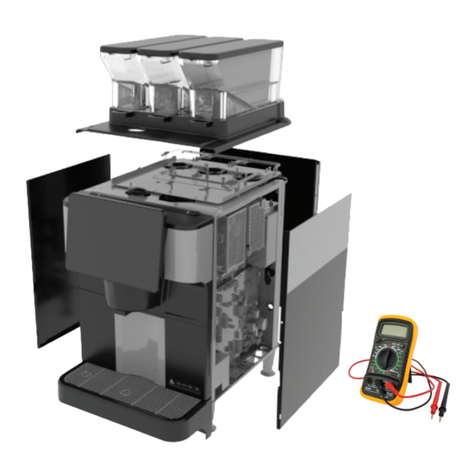

BREWING TEMPERATURE

1. Measure the brew water temperature at

the spray head. The temperature should

be 195 Degrees or higher. A suitable

digital thermometer is available from

Coca-Cola Parts (CCP#121235).

2. If the water is not 195 Degrees (+

_ 10°F):

• The temperature probe and/or

thermostat may not be functioning

properly.

• The temperature probe and boiler may

be coated with lime scale from the

hardness in the water.

3. Call 1-800-241-COKE (2653) for service.

SERVING TEMPERATURE

1. Never use a warm glass.

2. Always use correct Ice Fill.

TasteTemperature

Brew it Right

It is important to make sure that brewed tea

equipment is operating properly. Calibrating

the brew and dilution flow rates will help to

ensure that the brewed tea concentration

is not too weak or too

strong.

1. Use the control panel to access Level 2

Programming; skip to Calibrate Flow.

• Follow instructions to collect, measure

and adjust the Spray Head Cal. (brew

water) – make sure an empty tea

brewing funnel is in place.

• Repeat for the Dilution Cal. (make-up

water)

• Measure volumes using graduated

pitchers, available from Coca-Cola

Parts:

• 2L pitcher: CCP#116967

• 3L pitcher: CCP#122566

IS THE FUNNEL

INTERIOR CLEAN?

IS THE STRAINER CLEAN?

The flow of brew water/tea through the

funnel must not be slowed because of a

clogged or dirty strainer. The interior of

the funnel should not have any stains or

residues that might add bitter notes to the

tea. Replacement funnel tip & screen kit

(pictured) is available from Coca-Cola Parts,

#121048.

For more information, refer

to the ITCB Brew Volume

Calibration Instructions from

BUNN, found on their website

www.bunn.com.

1. Check the date code on the case:

Each case of tea bags is stamped

with a date code indicating the

“Enjoy By” date. The date code is

on a label affixed to the box.

2. Rotate your BIB and tea bag stock.

Always use the oldest tea bags and

liquid sweetener first to maintain

freshness. Remember First to Enjoy

By…First Out!

3. Avoid using tea bags and sweet-

ener that are too old. Tea bags and

sweetener should be used before

“Enjoy By” date. The shelf life for

each product from the date of each

manufacturer is:

Gold Peak Black Tea = 18 months.

MIS sweetener = 120 days.

4. Discard the tea bags from the brew

basket immediately after the brew

cycle is finished. NEVER

RE-USE TEA BAGS.

5. The maximum hold time is 6 (six)

hours. To help ensure the tea you

serve is always fresh, a brew date

sticker is available via the Coke

Catalog for use with your dispenser

urns. Place the sticker on the side of

the urn and simply write in the date

and time the tea was placed in the

urn. Contact your Coca-Cola sales

representative should you want

these stickers.

6. Store tea at room temperature away

from items that could

impact taste (e.g. onions).

7. Keep boxes closed when not

in use to avoid moisture getting into

the box which can cause mold.

First to Enjoy By...First Out!

Why It’s Important

Remember, great taste is why your customer

orders iced tea. Your customers expect

to experience great tasting, fresh brewed

iced tea! Fresh tea bags are essential to

producing quality brewed iced tea.

What to Check

Tea Bags and liquid sweetener produced

by The Coca-Cola Company for your fresh

brewed tea are packaged by the case and by

2.5 BIB. To make certain you always serve

only fresh tea bags and liquid sweetener, pay

attention to these conditions:

Freshness

PREPARATION FOR 3 GALLON BREW

1. Begin each brew cycle with a clean, empty brew funnel and urn.

(Be sure the urn lid doesn’t interfere with the flow of dilution water.)

2.

Use 1 (one) tea bag for each complete brew cycle.

3.

Make sure to use the GRAY COLORED quick brew, brew basket.

4.

Place the tea bag in the center of the brew

basket and replace the brew basket in the

brewer. (Figure A)

5. Slide the funnel into the funnel rails until it

stops.

6. Make sure the “ON/OFF” switch is “ON”

and the LED light is lit.

7.

Ensure the display screen message

indicates the brewer is ready to brew.

BREW IT RIGHT

For UNSWEET TEA:

1. Press the button labeled “FULL” and

make sure the indicator light comes on,

then press the button labeled “UNSWEET ICED TEA”

to begin brew cycle.

2. After brew cycle has finished and tea no longer drips from the

funnel tip, carefully remove the brew funnel and discard used tea

bags. NEVER RE-USE TEA BAGS.

3. Immediately place the lid on the urn.

4. Discard product after 6 (six) hours.

For SWEET TEA:

1. Press the button labeled “FULL” and make sure

the indicator light comes on, then press the

button labeled “SWEET ICED TEA” to begin

brew cycle.

2. After brew cycle has finished and tea no longer

drips from the funnel tip, carefully remove the

brew funnel and discard used tea bags. NEVER

RE-USE TEA BAGS.

3. Wear a foodservice glove, and use a clean, stain-

less steel spoon (or whisk) sufficient in length to

reach the bottom of the container holding the tea.

4. Mix, stirring enough times until all the sweetener

is evenly distributed through

the container.

5. Immediately place the lid on the urn.

6. Discard product after 6 (six) hours.

Figure A To make sure you are

serving quality iced tea,

just follow these steps:

Use the appropriate label to identify the

flavor contained in each urn

Brew date sticker

Sweetener Port

Water Ports

* Always use extreme care when dealing

with beverages of high temperatures.