Ratek RSM7DC Rotary Suspension Mixer – User Manual

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Page 3 of 16

TABLE OF CONTENTS

PAGE

Cash Bo

NTENDED USE................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.....................................

..........

..... 4

44

4

Suitable Articles For Use With This Rotary Suspension Mixer ........................................................................................................... 4

Unsuitable Articles For Use With This Rotary Suspension Mixer ........................................................................................................ 4

Suitable Environments For The Rotary Suspension Mixer ................................................................................................................. 4

General Operation .................................................................................................................................................................. 4

OPERATOR RESPONS B L TY – SAFETY CONS DERAT ONS ................................

................................................................

................................................................

................................................................

................................................................

................................................................

..............................................

............................

.............. 4

44

4

Conditions of Operation............................................................................................................................................................ 4

Safety Labels And Markings ...................................................................................................................................................... 5

OPERAT NG PROCEDURES................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................................

..............................................

....................... 6

66

6

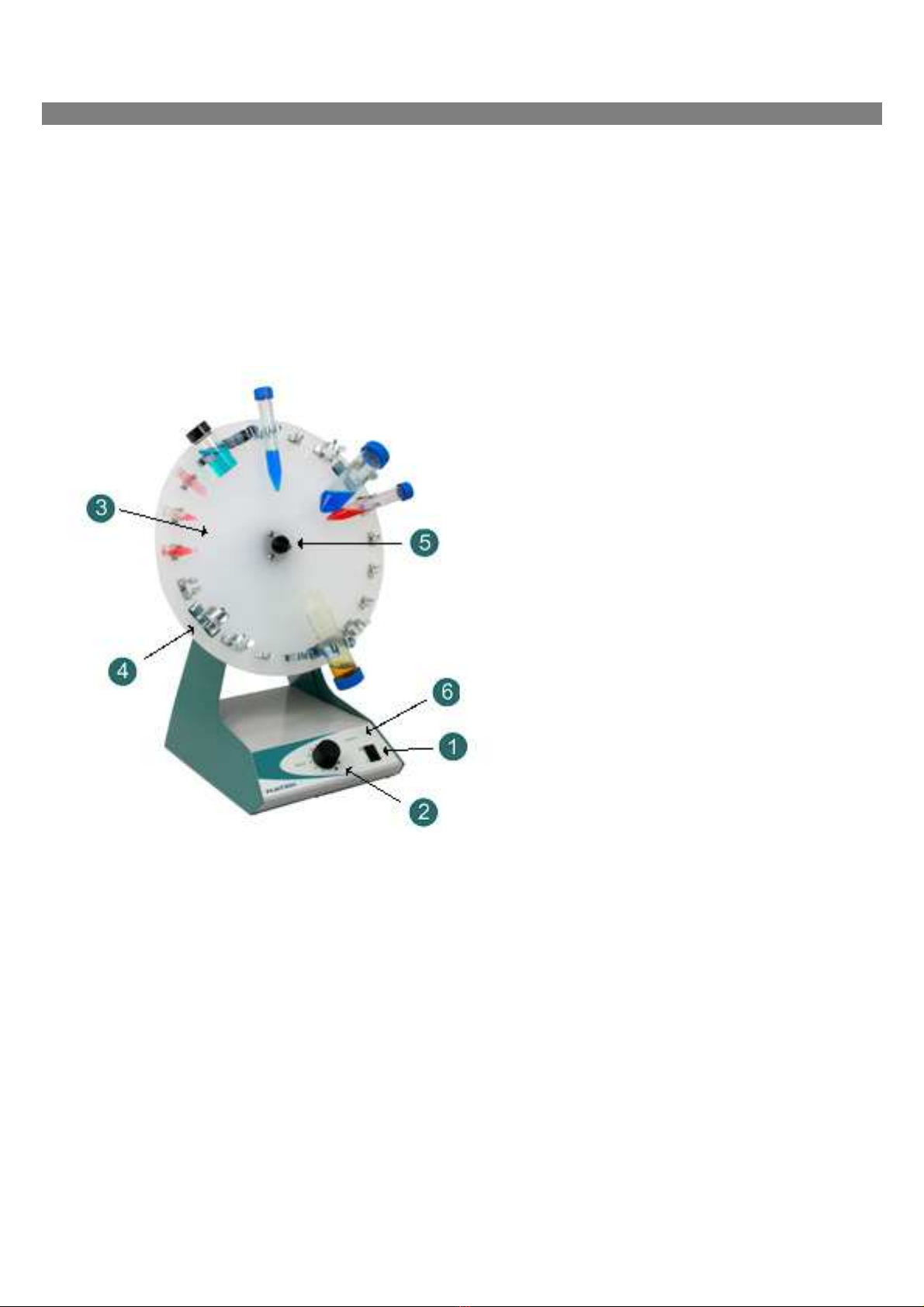

Identification of Controls & Functions .......................................................................................................................................... 6

Safety Warnings..................................................................................................................................................................... 7

Safety Recommendations .........................................................................................................................................................7

Preparation & Installation.........................................................................................................................................................8

Using The Rotary Suspension Mixer............................................................................................................................................ 9

ROUT NE CLEAN NG AND MA NTENANCE................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.................................

..

. 11

1111

11

TECHN CAL SPEC F CAT ONS ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.................................................

..................................

................. 13

1313

13

D SPOSAL................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................

..................

......... 13

1313

13

EMC CONFORM TY ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................................

..........................................................

............................. 13

1313

13

RATEK SERV CE CONTACT NFORMAT ON................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.................................

..

. 14

1414

14

TROUBLESHOOT NG................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................................

..........................................................

............................. 14

1414

14

WARRANTY COND T ONS ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.....................................................

..........................................

..................... 15

1515

15