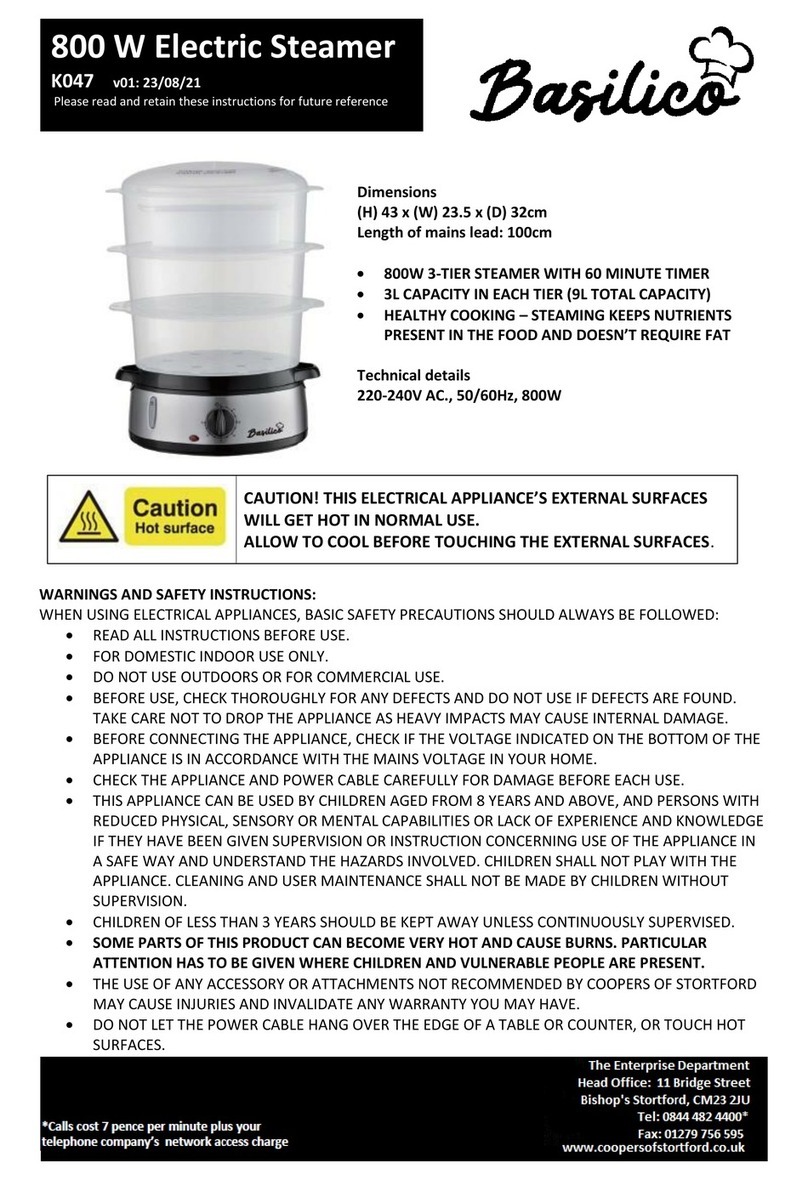

Safety Instructions

8 / 72

Keep this manual in a safe place so that it can always be consulted by anyone using the

appliance.

This appliance may not be used by children or people with limited physical, sensor or mental

capacity or those without the necessary experience and/or knowledge, unless such people

are supervised by a person who is responsible for their safety.

Operate using hands only. Damage caused by the use of pointed, sharp or other objects will

invalidate the warranty.

We recommend regular training of your staff to avoid the risk of accident or damage to the

appliance. Operators must also receive regular safety instruction.

In the event that the connection cable becomes damaged, it must be replaced by the

manufacturer, a service agent or qualified specialists to prevent any hazards or damages

to the appliance.

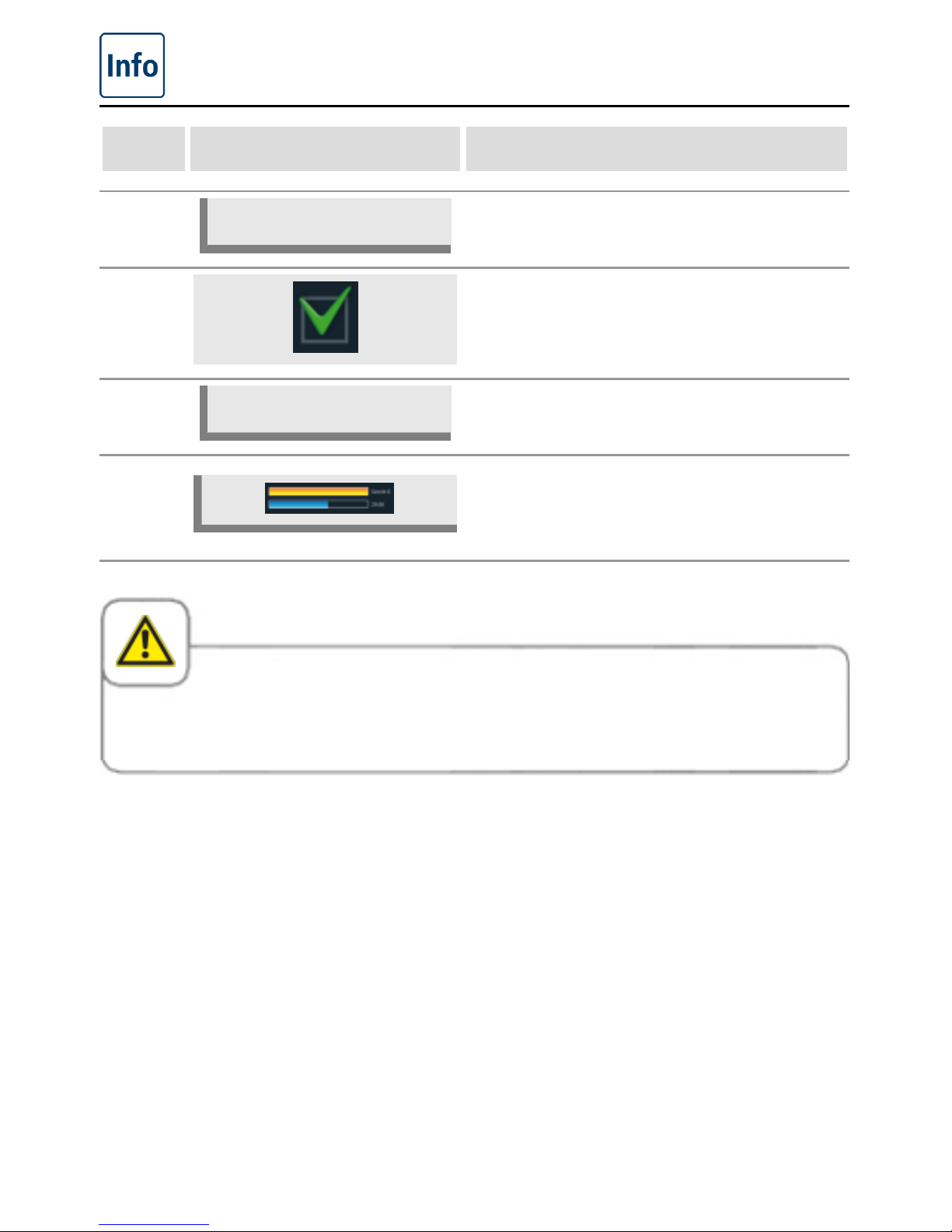

If the appliance is installed in a position where the highest rack is higher than 160 cm, the

supplied sticker must be affixed to the appliance.

Warning!

Daily checks before switching on and use

-Lock the air baffle at the top and bottom as per the instructions - risk of injury from the

rotating fan wheel.

-Make sure that the hanging racks or mobile oven rack are correctly locked in place in the

cooking chamber - containers with hot liquids can fall through or slip out of the cooking

chamber - risk of combustion.

-Make sure that there are no cleaning tab residues in the cooking chamber before you start

cooking with the appliance. Thoroughly rinse away any cleaning tab residues with the hand

shower - risk of chemical burns.