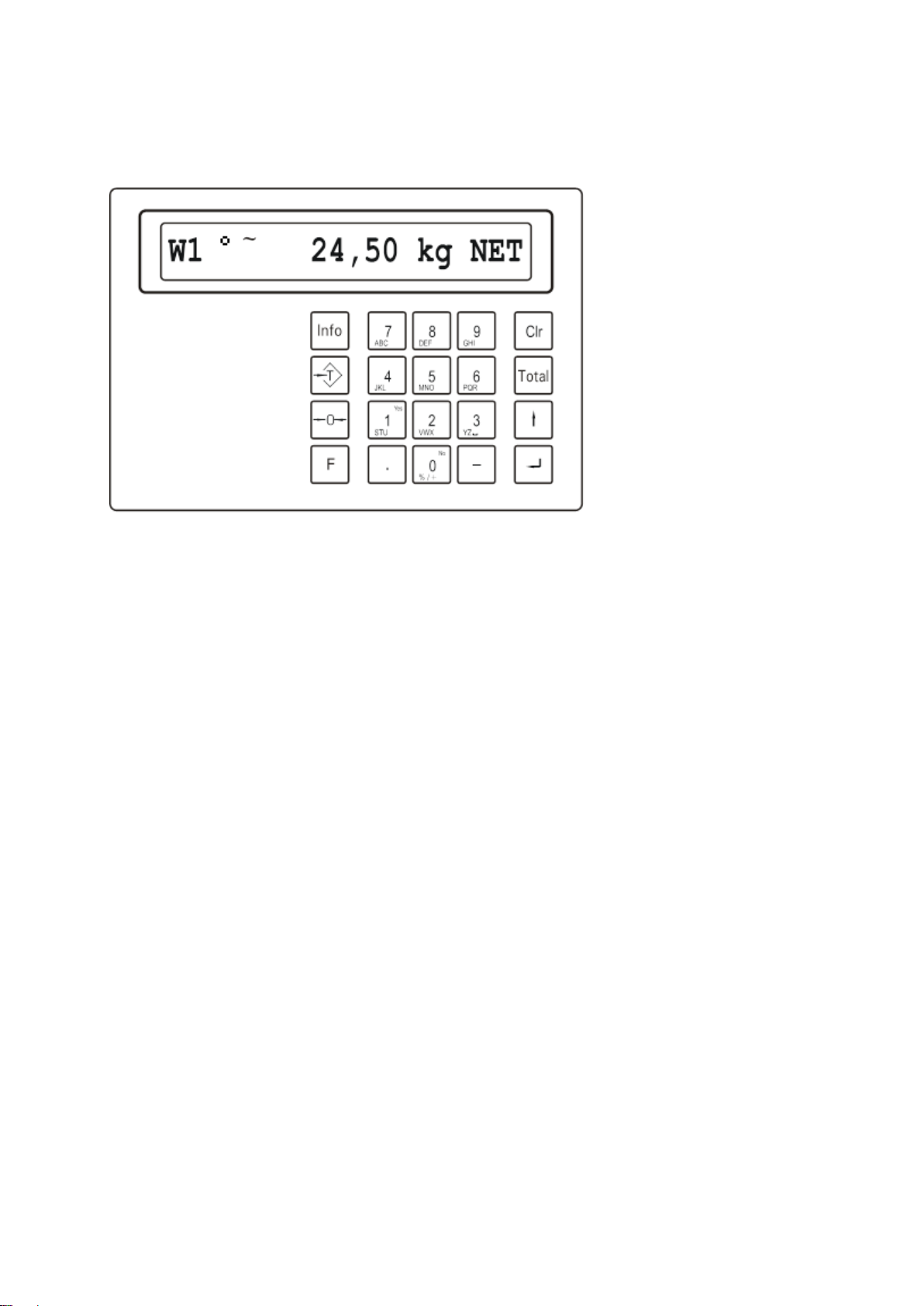

3. FUNCTIONS INDICATOR

3.1 GENERAL

3.1.1 SWITCHING INDICATOR ON/OFF

The indicator is switched on by pressing the key. Pressing the F7 key will switch of

the indicator. To save the life span of a charged battery, the indicator will switched off

automatically after 15 minutes of load stability.

If the battery level is too low, a rectangle will flash on the right of the display to show

that the battery needs to be charged. After 2 minutes the indicator will turn off

automatically.

3.1.2 DATE & TIME ADJUST

After switching on of the indicator the display gives sequentially the following

information: IT3000M..” (initialization takes about 12 sec.) software version number,

date/time and the active programme (BASIC or COUNT). This information can also

be displayed by pressing the key.

Adjusting date & time is done in the supervisor mode. This is done like this:

Press F8 to activate the supervisor mode.

The display gives the text “Supervisor mode” and “Password [2958].

Key in password (a wrong password will give “Invalid Password”. With the key

you can go back to the normal weighing mode.)

On the display appears “Choose: Parameter”.

Confirm with

The display shows the entered date & time.

Change the date with the numeric key path and confirm with

(or confirm the current setting of the date with).

The display shows the entered time.

Change the time with the numeric key path and confirm with

(or confirm the current setting of the time with ).

The display shows “Ticket nr.”.

Scroll through the other items in the supervisor mode by pressing the key

several times.

The display shows “Saving”, the entered values will be stored

On the display appears ‘’Choose: Parameter”.

To return to the weighingprogramme push ↑

The indicator returns returns to the weighing programme.