METRICFATS.COM!

Thank&you&for&purchasing&your&new&POWER8PUC™!Wheel&Lighting&Kit.&

The instructional sheets that follow are thoroughly detailed and should be studied

BEFORE picking up a tool. Take your time, work safe and you will enjoy your new

POWER-PUC™ Wheel Lights within a few hours.

ATTENTION: You should ALWAYS disconnect your battery before performing any

electrical work.

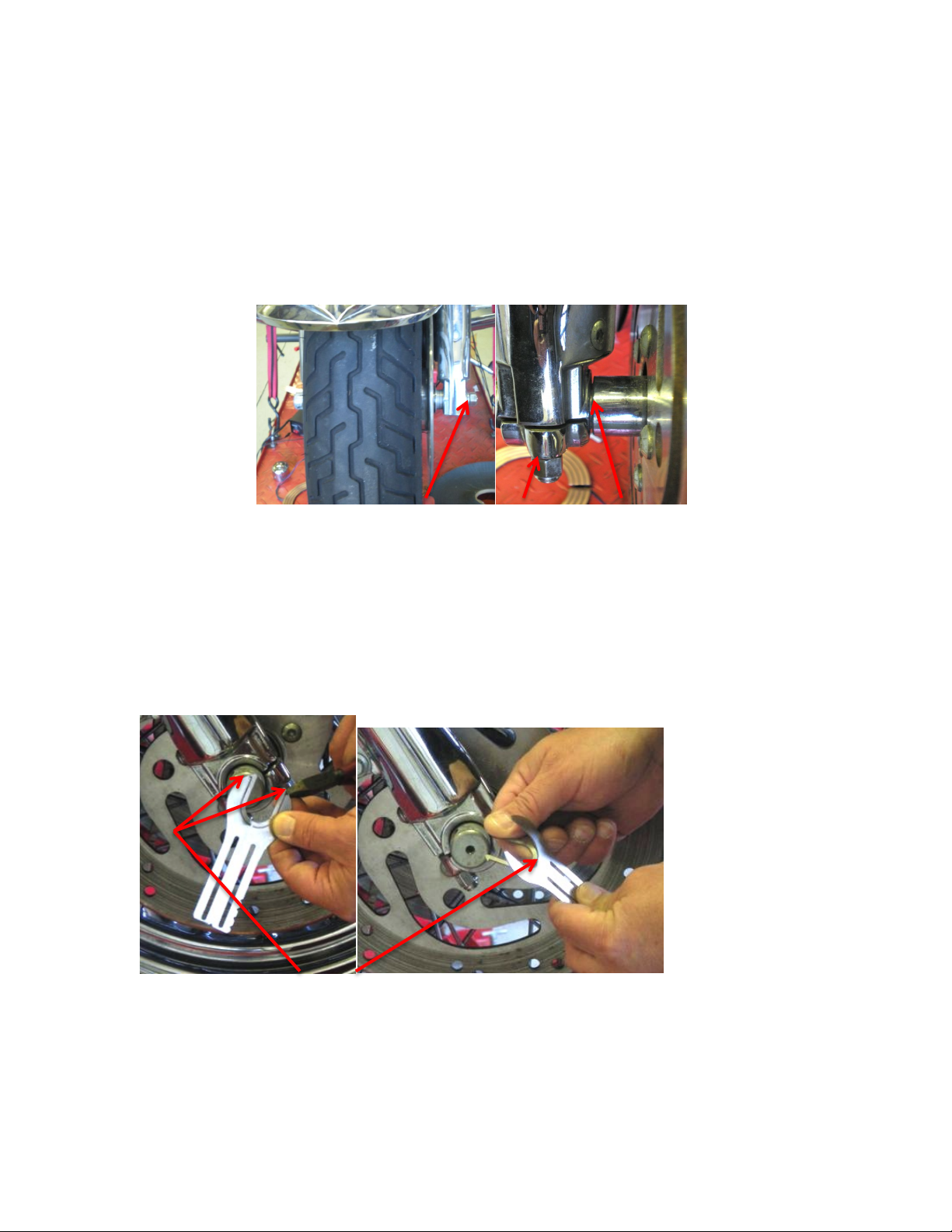

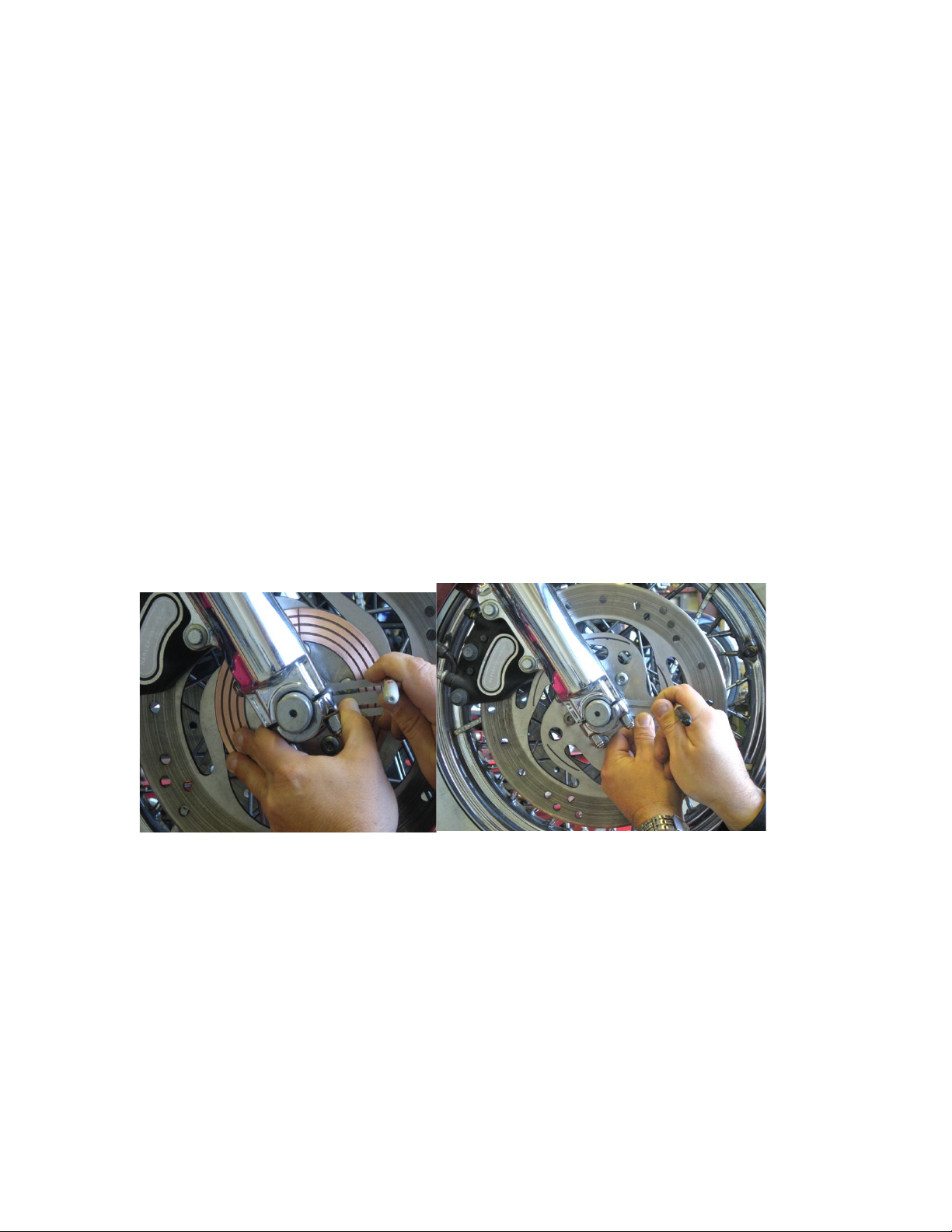

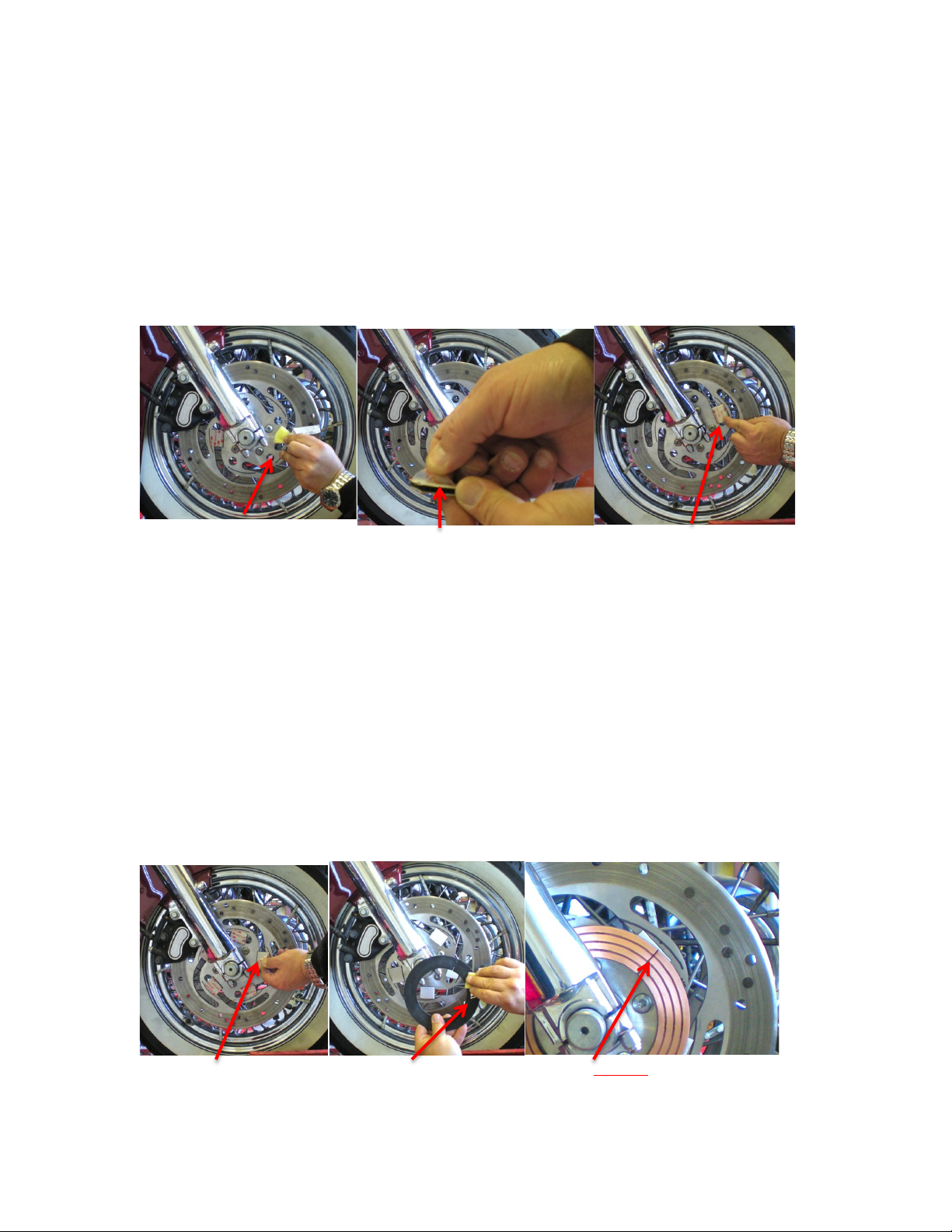

Although the following instructions show a particular make and model of bike, virtually

every installation process will be identical regardless of bike. Also, the bike shown has a

completely flat rotor. Yours may be different. Not to worry. POWER-PUCs are made to

fit your particular bike. In some cases you may find it easier to install the rear PUC on the

drive sprocket or pulley instead of the rotor (recommended location is normally marked

on packaging). As long as you have read the following instructions and are aware of the

general operation of the system, you should have no problem. Lastly, these instructions

address installation of the PUCs themselves. Because of almost limitless combinations,

detailed instructions for installation of LEDs on the wheels is impractical. However, there

may be a future article on some simple layouts. But if you have a basic knowledge of 12

volt wiring and use some common sense you should not have any issue installing LEDs.

Just remember, ANYWHERE you will be using double-stick tape, the surface

MUST be perfectly clean. Also, all wires, LEDs etc. that are on the wheels must be

thoroughly restrained.

Let’s get familiar with the kit and how it works.

(Pictures are representative only. Your PUCs may be of different sizes)