Raychem XL-Trace User manual

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

H55838 2/12 www.tycothermal.com 1 of 44

Pipe Freeze Protection

and Flow Maintenance

This step-by-step design guide provides the tools necessary to design a Raychem XL-Trace

pipe freeze protection or flow maintenance system. For other applications or for design

assistance, contact your Tyco Thermal Controls representative or phone Tyco Thermal

Controls at (800)545-6258. Also, visit our web site at www.tycothermal.com.

Contents

Introduction..............................................................1

How to Use this Guide ....................................................2

Safety Guidelines ........................................................2

Warranty...............................................................3

System Overview..........................................................3

XL-Trace Applications.....................................................3

Self-Regulating Heating Cable Construction ....................................4

Pipe Freeze Protection Applications ...........................................5

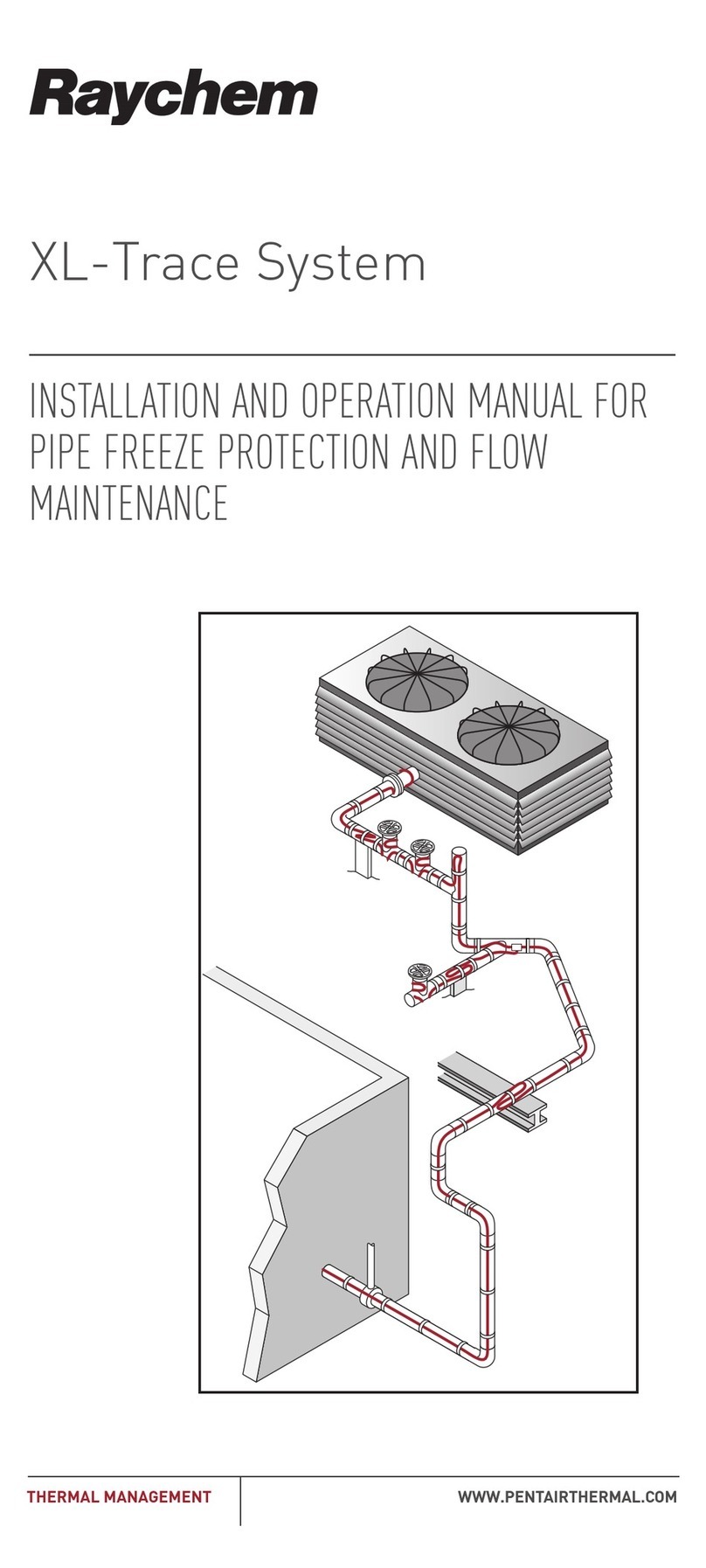

Typical Pipe Freeze Protection System ........................................5

General Water Piping .....................................................6

Fire Sprinkler Systems ....................................................8

Flow Maintenance Applications ...............................................9

Typical Flow Maintenance System ...........................................9

Greasy Waste Lines .....................................................10

Fuel Lines .............................................................12

Pipe Freeze Protection and Flow Maintenance Design.............................13

Design Step by Step .....................................................13

Step 1 Determine design conditions and pipe heat loss .....................13

Step 2Select the heating cable .......................................18

Step 3Determine the heating cable length ..............................20

Step 4Determine the electrical parameters..............................22

Step 5Select the connection kits and accessories ........................26

Step 6Select the control system......................................31

Step 7Select the power distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Step 8Complete the Bill of Materials ...................................36

XL-Trace System Pipe Freeze Protection and Flow Maintenance Design Worksheet ......37

Introduction

Raychem XL-Trace is designed for pipe freeze protection and flow maintenance in the

following applications:

• Freeze protection of general water piping (aboveground and buried)

• Freeze protection of fire sprinkler systems (aboveground and buried supply pipes)

• Flow waste lines (aboveground and buried)

• Flow maintenance of fuel lines (aboveground)

XL-Trace System

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

2 of 44 www.tycothermal.com H55838 2/12

This guide does not cover applications in which any of the following conditions exist:

• Hazardous locations, as defined in the national electrical codes

• Pipe temperature other than specified in Table 1 on page 3

• Pipe maintenance temperatures above 150°F (65°C)

• Supply voltage other than 120 V or 208–277 V

If your application conditions are different, or if you have any questions, contact your

Tyco Thermal Controls representative or contact Tyco Thermal Controls directly

at (800)545-6258.

How to Use this Guide

This design guide presents Tyco Thermal Controls’ recommendations for designing an XL-Trace

pipe freeze protection or flow maintenance system. It provides design and performance data,

electrical sizing information, and application configuration suggestions. Following these

recommendations will result in a reliable, energy-efficient system.

OTHER REQUIRED DOCUMENTS

This guide is not intended to provide comprehensive installation instructions. For complete

XL-Trace pipe freeze protection and flow maintenance system installation instructions, please

refer to the following additional required documents:

• XL-Trace System Installation and Operation Manual (H58033)

• Additional installation instructions are included with the connection kits, thermostats,

controllers, and accessories

If you do not have these documents, you can obtain them from the Tyco Thermal Controls

web site at www.tycothermal.com.

For products and applications not covered by this design guide, please contact your Tyco

Thermal Controls representative or call Tyco Thermal Controls directly at (800)545-6258.

Safety Guidelines

As with any electrical equipment, the safety and reliability of any system depends on the

quality of the products selected and the manner in which they are installed and maintained.

Incorrect design, handling, installation, or maintenance of any of the system connection kits

could damage the system and may result in inadequate performance, overheating, electric

shock, or fire. To minimize these risks and to ensure that the system performs reliably, read

and carefully follow the information, warnings, and instructions in this guide.

This symbol identifies important instructions or information.

This symbol identifies particularly important safety warnings that must be followed.

WARNING: To minimize the danger of fire from sustained electrical arcing if the

heating cable is damaged or improperly installed, and to comply with the requirements of

Tyco Thermal Controls, agency certifications, and national electrical codes, ground-fault

equipment protection must be used on each heating cable branch circuit. Arcing may not

be stopped by conventional circuit protection.

H55838 2/12 www.tycothermal.com 3 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

System Overview

Warranty

Tyco Thermal Controls’ standard limited warranty applies to all products.

An extension of the limited warranty period to ten (10) years from the date of installation is

available if a properly completed online warranty form is submitted within thirty (30) days

from the date of installation. You can access the complete warranty on our web site at

www.tycothermal.com.

System Overview

The XL-Trace system provides freeze protection and flow maintenance for aboveground

and buried pipe applications. The XL-Trace system is based on self-regulating heating cable

technology. Tyco Thermal Controls offers the option of three self-regulating heating cables

with the XL-Trace system: 5XL, 8XL, and 12XL (208–277 V only) for applications using 120 and

208–277 V power supplies. The cable’s output is reduced automatically as the pipe warms,

so there is no possibility of failure due to overheating.

An XL-Trace system includes the heating cable, power connection, splice, tee connections,

controls, contactors, power distribution panels, accessories, and the tools necessary

for a complete installation.

XL-Trace Applications

Identify which of the standard XL-Trace applications below pertain to your installation.

Proceed to the appropriate design sections that follow.

Table 1 XL-Trace Applications

Application Description

Specific application

requirements

Pipe freeze protection

General water piping Freeze protection (40°F [4°C]

minimum) of insulated, metal or

plastic water piping

“Aboveground piping,” page 6

“Buried piping,” page 7

Sprinkler piping Freeze protection (40°F [4°C]

minimum) of standpipes up to

20", supply pipes and branch lines

with sprinklers

“Standpipes, supply pipes, and

branch lines with sprinklers” on

page 8. Also see “XL-Trace

System for Fire Sprinkler Freeze

Protection Design Guide” (H58489).

Flow maintenance

Greasy waste lines Flow maintenance (110°F [43°C]

minimum) for insulated greasy

waste lines

“Aboveground piping” on page 10

“Buried piping” on page 11

Fuel lines Flow maintenance (40°F [4°C]

minimum) for insulated metal

piping containing #2 fuel oil

“For aboveground piping only,”

page 12

Note: If your application does not fit these guidelines, contact your local Tyco Thermal

Controls representative or call (800) 545-6258.

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

4 of 44 www.tycothermal.com H55838 2/12

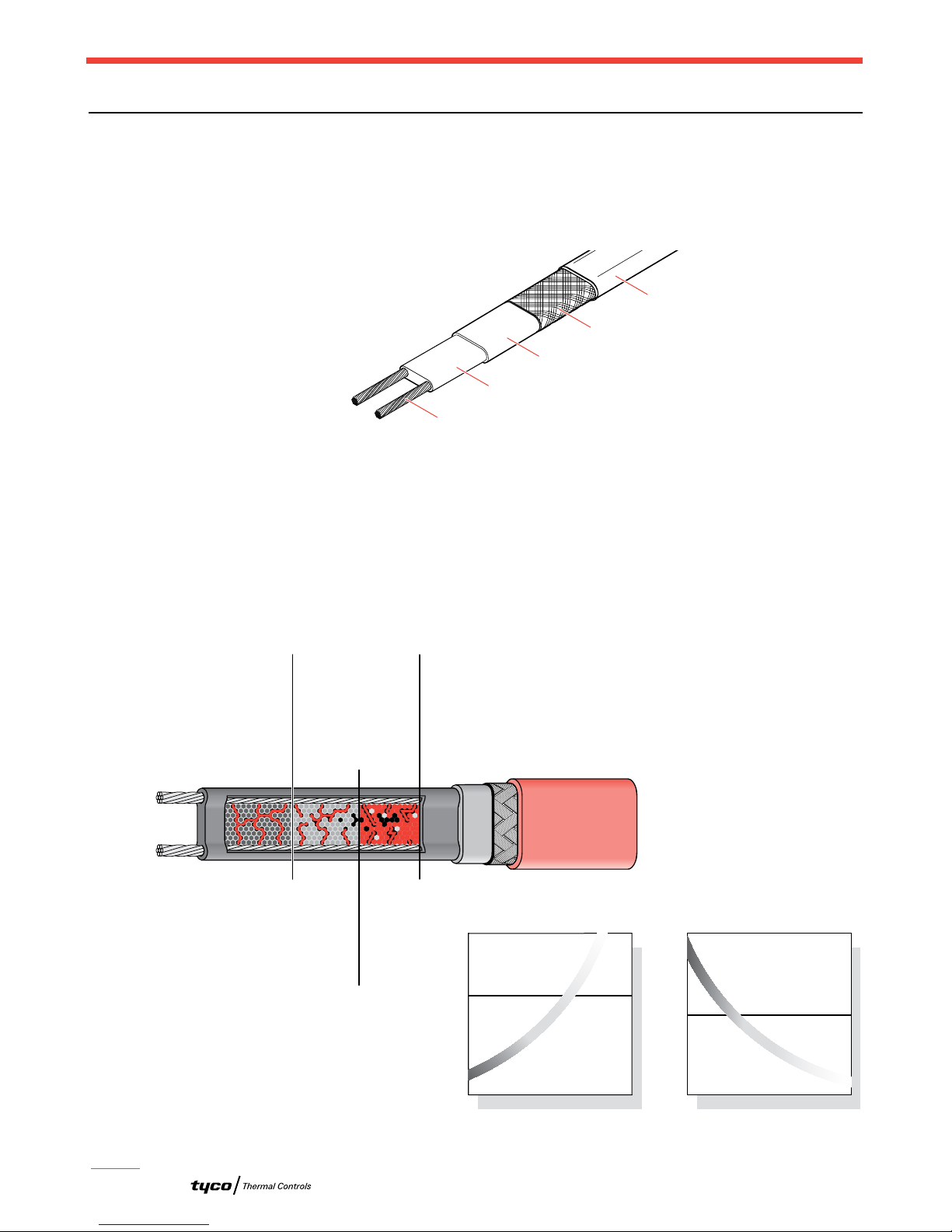

Self-Regulating Heating Cable Construction

Raychem XL-Trace self-regulating heating cables are comprised of two parallel nickel-coated

bus wires in a cross-linked polymer core, a tinned copper braid, and a fluoropolymer or

polyolefin outer jacket. These cables are cut to length, simplifying the application design and

installation.

Fig. 1 XL-Trace heating cable construction

With self-regulating technology, the number of electrical paths between bus wires changes in

response to temperature fluctuations. As the temperature surrounding the heater decreases,

the conductive core contracts microscopically. This contraction decreases electrical resis-

tance and creates numerous electrical paths between the bus wires. Current flows across

these paths to warm the core.

As the temperature rises, the core expands microscopically. This expansion increases

electrical resistance and the number of electrical paths decreases. The heating cable

automatically reduces its output.

At low temperature,

there are many

conducting paths,

resulting in high output

and rapid heat-up. Heat

is generated only when it

is needed and precisely

where it is needed.

At high temperature,

there are few conducting

paths and output is

correspondingly lower,

conserving energy

during operation.

At moderate temperature,

there are fewer conducting

paths because the heating

cable efficiently adjusts by

decreasing output, eliminating

any possibility of overheating.

The following graphs illustrate the response of self-regulating heating cables to

changes in temperature. As the temperature rises, electrical resistance increases,

and our heaters reduce their power output.

Temperature

Resistance

Power

Temperature

Constant wattage

Constant wattage

Self-regulating

Self-regulating

Fig. 2 Self-regulating heating cable technology

Nickel-plated copper bus wire

Self-regulating conductive core

Modified polyolefin inner jacket

Tinned-copper braid

Polyolefin or

fluoropolymer outer jacket

H55838 2/12 www.tycothermal.com 5 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Pipe Freeze Protection Applications

Pipe Freeze Protection Applications

A pipe freeze protection system is designed to maintain water temperature at a minimum of

40°F (4°C) to prevent freezing.

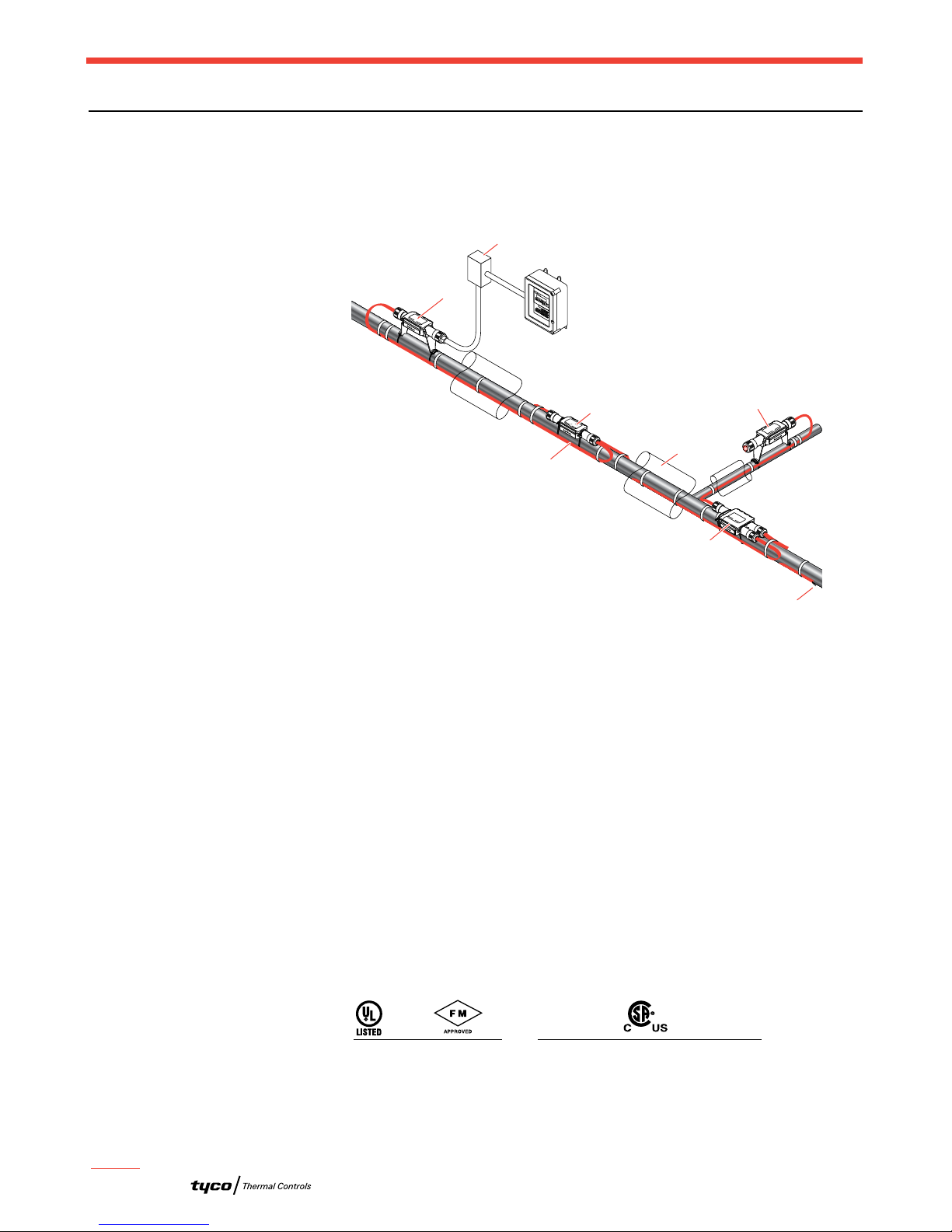

Typical Pipe Freeze Protection System

A typical pipe freeze protection system includes the XL-Trace self-regulating heating cables,

connection kits, ambient temperature control, and power distribution.

Fig. 3 Typical XL-Trace pipe freeze protection system

Lighted End Seal

Heating Cable

End Seal Kit

Tee Kit

Power Distribution Panel

Power Connection Kit Splice Kit Cross Kit

Ambient RTD

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

6 of 44 www.tycothermal.com H55838 2/12

General Water Piping

General water piping is defined as metal or plastic water piping located in nonhazardous

locations.

ABOVEGROUND PIPING

Fig. 4 Typical aboveground piping system

Application Requirements

The system complies with Tyco Thermal Controls requirements for aboveground general

water piping when:

• The heating cable is permanently secured to insulated metal pipes with GT-66 glass tape,

or to plastic pipes using AT-180 aluminum tape.

• A 30-mA ground-fault protection device (GFPD) is used.

• The heating cable is installed per manufacturer’s instructions with approved Raychem

connection kits. See Table 13 on page 27 and the XL-Trace System Installation and

Operation Manual (H58033).

Cable Selection

See “Other Required Documents” page 14.

Approvals

UL Listed, FM Approved, and c-CSA-us Certified for nonhazardous locations.

RayClic-PC

power connection

Junction

box

XL-Trace

heating cable

RayClic-S

splice

RayClic-T

tee

Insulation

RayClic-LE

lighted end seal

(optional)

RayClic-E

end seal

DigiTrace C910

Electronic controller

5XL1-CR, -CT

5XL2-CR, -CT 8XL1-CR, -CT

8XL2-CR, -CT 5XL1-CR, -CT

5XL2-CR, -CT 8XL1-CR, -CT

8XL2-CR, -CT 12XL2-CR, -CT

-w

H55838 2/12 www.tycothermal.com 7 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Pipe Freeze Protection Applications

BURIED PIPING

Fig. 5 Typical buried piping system

Application Requirements

The system complies with Tyco Thermal Controls requirements for use on buried insulated

metal or plastic pipe when:

• The pipeline is buried at least 2 feet deep.

• All heating cable connections (power, splice, tee, and end termination) are made above-

ground. No buried or in-conduit splices or tees are allowed.

• The heating cable has a fluoropolymer outer jacket (-CT).

• The power connection and end seal are made in UL Listed and CSA Certified junction

boxes above grade.

• The heating cable is protected from the pipe to the power connection box in UL Listed

and CSA Certified water-sealed conduit (minimum 3/4-inch diameter) suitable for the

location.

• A 30-mA ground-fault protection device (GFPD) is used.

• Closed-cell, waterproof thermal insulation with fire-retardant, waterproof covering is used.

• The heating cable is installed per manufacturer’s instructions with approved Tyco Thermal

Controls connection kits. See Table 15 on page 29 and the XL-Trace System Installation

and Operation Manual (H58033).

Cable Selection

See “Pipe Heat Loss Calculations,” page 14.

Approvals

UL Listed, FM Approved, and c-CSA-us Certified for nonhazardous locations.

RTD10CS

Insulation

Conduit

XL-Trace

heating cable

with -CT jacket

Ground

Alternate

power connection

Alternate

end seal

Ground

Wall

RayClic-LE*

RayClic-PC*

Junction box

RayClic-E

end seal

Conduit

Wall

with wall

mounting

bracket

with wall

mounting

bracket

FTC-XC

power

connection

*To protect the heating cable run it inside

Convolex tubing between the conduit and

the RayClic connection kits.

DigiTrace C910

Electronic controller

Conduit for

temperature

sensor

5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 12XL2-CT

-w

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

8 of 44 www.tycothermal.com H55838 2/12

Fire Sprinkler Systems

XL-Trace is designed to maintain fire suppression system standpipes, supply piping, mains,

feeders, branch lines and sprinklers at 40°F (4°C) in areas subject to freezing.

STANDPIPES, SUPPLY PIPES, AND BRANCH LINES WITH SPRINKLERS

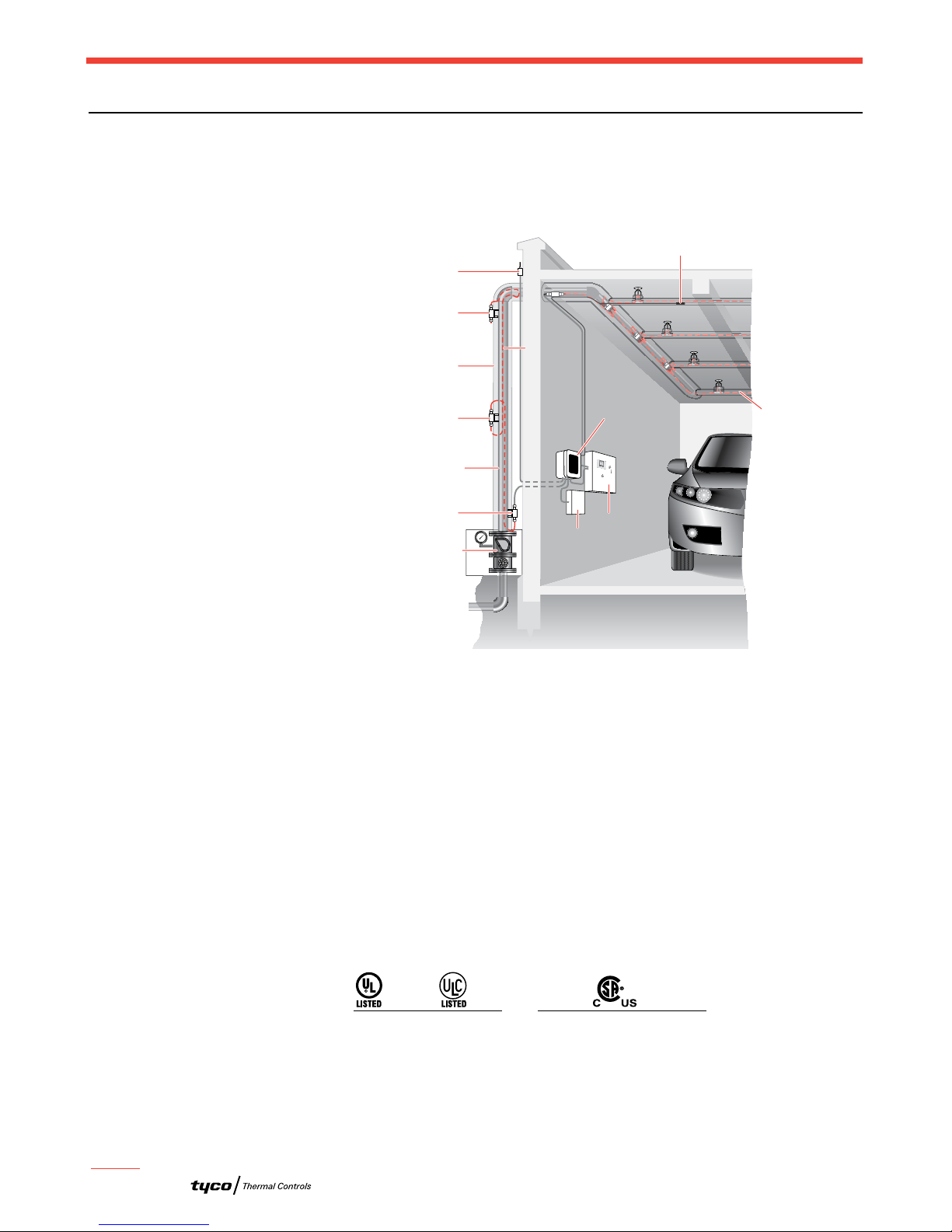

Fig. 6 Standard sprinkler standpipe heating system layout

Refer to the Fire Sprinkler System Freeze Protection Design Guide (H58489) for detailed in-

structions to design XL-Trace heating cable circuits to freeze protect aboveground or buried

supply pipe, feeders, mains standpipes, branch lines and sprinklers.

Approvals

The 2007 edition of NFPA 13 (Standard for the Installation of Sprinkler Systems) allows List-

ed electrical heat tracing to freeze protect fire suppression systems including supply lines,

standpipes and branch lines containing sprinklers. XL-Trace is c-CSA-us Certified for use on

fire suppression systms under CSA C22.2 No. 130-03 for Canada and IEEE 515.1-2005 for

the US. The system covered in this manual includes supply lines, standpipes, branch lines

and sprinkler heads.

XL-Trace systems are also UL and ULC Listed for freeze-protecting sprinkler supply lines,

standpipes up to 20 inches in diameter and branch lines not containing sprinklers.

Standpipe

Thermal insulation

Control valves

in heated enclosure

RayClic-PC

power connection

RayClic-S splice

RayClic-LE

lighted end seal

Ambient sensing RTD

Ground

XL-Trace

Power

distribution

panel

Fire

alarm

panel

DigiTrace C910

electronic

controller

Refer to Branch

Lines with

Sprinkler section

for information on

heat tracing

sprinkler heads.

Line sensing RTD

5XL1-CR, -CT

5XL2-CR, -CT 8XL1-CR, -CT

8XL2-CR, -CT 5XL1-CR, -CT

5XL2-CR, -CT 8XL1-CR, -CT

8XL2-CR, -CT

12XL2-CR, -CT (not for branch lines

with sprinklers and sprinkler heads)

-w

H55838 2/12 www.tycothermal.com 9 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Flow Maintenance Applications

Flow Maintenance Applications

A flow maintenance system is designed to maintain cooking greasy waste lines and #2 fuel

oil lines above the temperature at which the viscosity inhibits fluid flow.

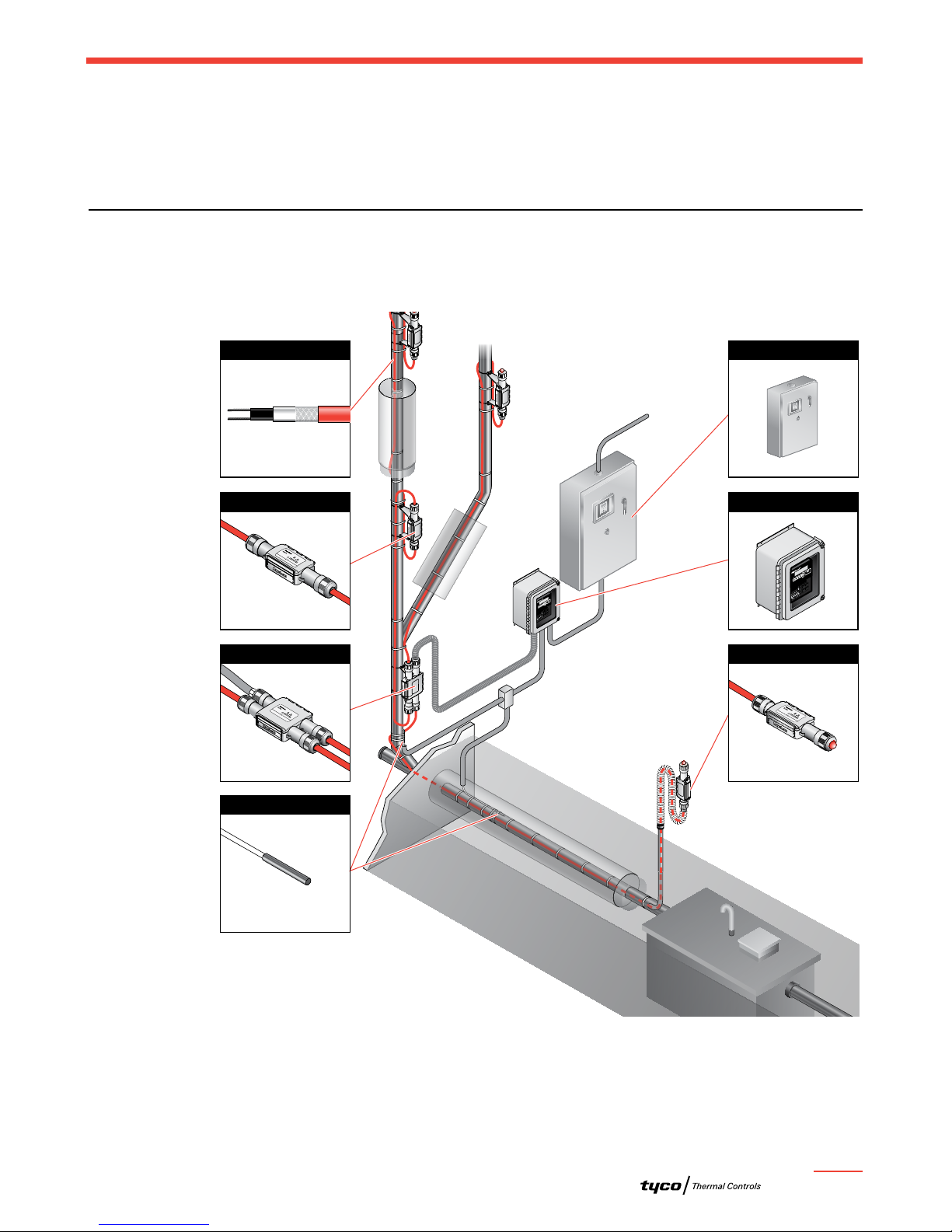

Typical Flow Maintenance System

A typical flow maintenance system includes the XL-Trace self-regulating heating cables with

a fluoropolymer outer jacket, connection kits, line-sensing temperature control and power

distribution.

Splice Kit

Powered Tee Kit

Heating Cable

Lighted End Seal

Power Distribution Panel

Grade

Electronic Controller

RTD

Fig. 7 Typical XL-Trace flow maintenance system

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

10 of 44 www.tycothermal.com H55838 2/12

Greasy Waste Lines

Greasy waste lines are defined as piping used for the disposal of waste oils and fats created in

the cooking process. Typical applications include greasy waste lines from commercial

restaurants. A grease-line flow maintenance system is designed to maintain a 110°F (43°C)

minimum fluid temperature.

ABOVEGROUND PIPING

Fig. 8 Typical aboveground piping system

Application Requirements

The system complies with Tyco Thermal Controls requirements for aboveground greasy

waste lines when:

• The heating cable is permanently secured to metal pipes with GT-66 glass tape, or to

plastic pipes using AT-180 aluminum tape.

• The heating cable must have a fluoropolymer outer jacket (-CT).

• A 30-mA ground-fault protection device (GFPD) is used.

• Tees and splices are installed using pipe mounting brackets, not in direct contact with

piping.

• The heating cable is installed per manufacturer’s instructions with approved Tyco Thermal

Controls connection kits. See Table 13 on page 27 and the XL-Trace System Installation

and Operation Manual (H58033).

Cable Selection

See “Pipe Heat Loss Calculations,” page 14.

Approvals

XL-Trace systems (-CT only) are UL Listed, FM Approved, and c-CSA-us Certified for

nonhazardous locations.

RayClic-PC

power

connection

Junction

box

RayClic-S

splice

Insulation

RayClic-LE

lighted end seal

RayClic-E

Alternate

end seal

XL-Trace

heating cable

with -CT jacket

RayClic-SB-04

pipe mounting bracket

DigiTrace C910

Electronic controller

RTD10CS

5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 12XL2-CT

-w

H55838 2/12 www.tycothermal.com 11 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Flow Maintenance Applications

BURIED PIPING

Fig. 9 Typical buried greasy waste line

Application Requirements

The system complies with Tyco Thermal Controls requirements for buried greasy waste lines

when:

• The heating cable is permanently secured to metal pipes with GT-66 glass tape, or to

plastic pipes using AT-180 aluminum tape.

• The heating cable must have a fluoropolymer outer jacket (-CT).

• The pipeline is buried at least 2 feet deep.

• All heating cable splices or tees are made aboveground. No buried or in-conduit splices

or tees are allowed.

• The power connection and end seal are made in UL Listed and CSA Certified junction

boxes above grade.

• The heating cable is protected from the pipe to the power connection box in UL Listed

and CSA Certified conduit (minimum 3/4-inch diameter) suitable for the location.

• A 30-mA ground-fault protection device (GFPD) is used.

• Closed-cell, waterproof thermal insulation with fire-retardant, waterproof covering is used.

• The heating cable is installed per manufacturer’s instructions with approved Tyco Thermal

Controls connection kits. See Table 15 on page 29 and the XL-Trace System Installation

and Operation Manual (H58033).

Cable Selection

See “Heating Cable Catalog Number” on page 18.

Approvals

XL-Trace systems (-CT only) are UL Listed, FM Approved, and c-CSA-us Certified for

nonhazardous locations.

RTD10CS

Insulation

Conduit

XL-Trace

heating cable

with -CT jacket

Ground

Alternate

power connection

Alternate

end seal

Ground

Wall

RayClic-LE*

RayClic-PC*

Junction box

RayClic-E

end seal

Conduit

Wall

with wall

mounting

bracket

with wall

mounting

bracket

FTC-XC

power

connection

*To protect the heating cable run it inside

Convolex tubing between the conduit and

the RayClic connection kits.

DigiTrace C910

Electronic controller

Conduit for

temperature

sensor

5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 12XL2-CT

-w

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

12 of 44 www.tycothermal.com H55838 2/12

Fuel Lines

Fuel lines are defined as those carrying #2 fuel oil. A fuel line flow maintenance system is

designed to maintain a 40°F (4°C) minimum fluid temperature to maintain flow.

FOR ABOVEGROUND PIPING ONLY

Fig. 10 Typical aboveground piping system

Application Requirements

The system complies with Tyco Thermal Controls requirements for aboveground #2 fuel oil

piping when:

• The heating cable is permanently secured to metal pipes with GT-66 glass tape, or to

plastic pipes using AT-180 aluminum tape.

• The heating cable must have a fluoropolymer outer jacket (-CT).

• Tees and splices are installed using pipe mounting brackets, not in direct contact with

piping.

• A 30-mA ground-fault protection device (GFPD) is used.

• The heating cable is installed per manufacturer’s instructions with approved Tyco Thermal

Controls connection kits. See Table 13 on page 27 and the XL-Trace System Installation

and Operation Manual (H58033).

Cable Selection

See “Pipe Heat Loss Calculations,” page 14.

Approvals

XL-Trace systems (-CT only) are UL Listed, FM Approved, and c-CSA-us Certified for

nonhazardous locations.

RayClic-S

splice

XL-Trace

heating cable

with -CT jacket

RTD10CS

RayClic-LE

lighted end seal

Junction

box

Insulation

RayClic-PC

power

connection

RayClic-SB-04

pipe mounting bracket

DigiTrace C910

Electronic controller

5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 5XL1-CT

5XL2-CT 8XL1-CT

8XL2-CT 12XL2-CT

-w

H55838 2/12 www.tycothermal.com 13 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Pipe Freeze Protection and Flow Maintenance Design

Pipe Freeze Protection and Flow Maintenance Design

This section details the design steps necessary to design your application. The examples

provided in each step are intended to incrementally illustrate the project parameter output for

two sample designs from start to finish. As you go through each step, use the “XL-Trace System

Pipe Freeze Protection and Flow Maintenance Design Worksheet,” page 37, to document your

project parameters, so that by the end of this section you will have the information you need

for your Bill of Materials.

XL-Erate, the commercial pipe freeze protection and flow maintenance design software is

available at http://www.tycothermal.com to assist with your design.

Design Step by Step

Your system design requires the following essential steps.

Determine design conditions and pipe heat loss

Select the heating cable

Determine the heating cable length

Determine the electrical parameters

Select the connection kits and accessories

Select the control system

Select the power distribution

Complete the Bill of Materials

Pipe Freeze Protection

and Flow Maintenance

1. Determine design

conditions and heat

loss

2. Select the heating

cable

3. Determine the

heating cable length

4. Determine the

electrical parameters

5. Select the

connection kits and

accessories

6. Select the control

system

7. Select the power

distribution

8. Complete the Bill of

Materials

Step Determine design conditions and pipe heat loss

Collect the following information to determine your design conditions:

• XL-Trace application (from Table 1Location

– Indoors

– Outdoors

– Aboveground

– Buried

• Maintain temperature (TM)

• Maximum system temperature (TMAX)

• Minimum ambient temperature (TA)

• Pipe diameter and material

• Pipe length

• Thermal insulation type and thickness

• Supply voltage

Example: Pipe Freeze Protection – Water Piping

Location Aboveground, outdoor

Maintain temperature (TM) 40°F (4°C)

Maximum system temperature (TMAX) 80°F (27°C)

Minimum ambient temperature (TA) –20°F (–29°C)

Pipe diameter and material 2-inch plastic

Pipe length 300 ft (91 m)

Thermal insulation type and thickness 1-inch fiberglass

Supply voltage 120 V

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

14 of 44 www.tycothermal.com H55838 2/12

Example: Pipe Freeze Protection – Greasy Waste Line

Location Buried

Maintain temperature (TM) 110°F (43°C)

Maximum system temperature (TMAX) 125°F (52°C)

Minimum ambient temperature (TA) 50°F (10°C) (soil temperature)

Pipe diameter and material 4-inch metal

Pipe length 200 ft (61 m)

Thermal insulation type and thickness 1-inch rigid cellular urethane

Supply voltage 208 V

PIPE HEAT LOSS CALCULATIONS

To select the proper heating cable you must first determine the pipe heat loss. To do this you

must first calculate the temperature differential (DT) between the pipe maintain temperature

and the minimum ambient temperature.

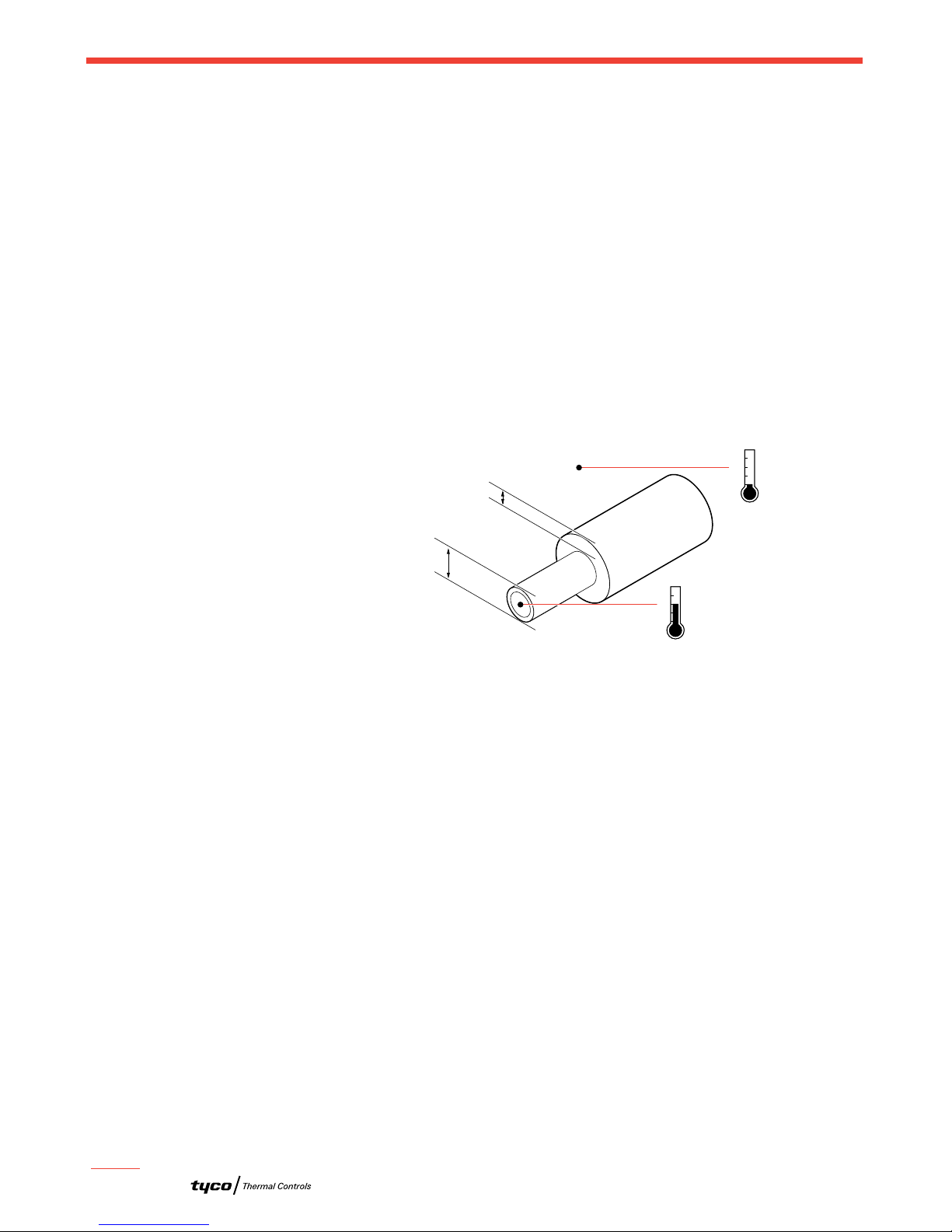

Fig. 11 Pipe heat loss

Calculate temperature differential DT

To calculate the temperature differential (DT), use the formula below:

DT = TM– TA

Example: Pipe Freeze Protection – Water Piping

TM40°F (4°C)

TA–20°F (–29°C)

DT = 40°F – (–20°F) = 60°F

DT = 4°C – (–29°F) = 33°C

Example: Flow Maintenance – Greasy Waste Line

TM110°F (43°C)

TA50°F (10°C)

DT = 110°F – (50°F) = 60°F

DT = 43°C – (10°C) = 33°C

Determine the pipe heat loss

Match the pipe size, insulation thickness, and temperature differential (DT) from Table 2 to

determine the base heat loss of the pipe (QB).

Example: Pipe Freeze Protection – Water Piping

Pipe diameter 2 inch

20

40

60

80

−40

−20

0

+20

+40

Maintain

temperature

°F

°F

Minimum

ambient

temperature

Thermal insulation thickness

Pipe or

tubing

diameter

H55838 2/12 www.tycothermal.com 15 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Pipe Freeze Protection and Flow Maintenance Design

Insulation thickness 1 inch

DT 60°F (33°C)

Heat loss (QB) for 60°F must be calculated through interpolation between DT at 50°F and DT

at 100°F from Table 2. For difference between the DT of 50°F and the DT of 100°F:

QB-50 3.2 W/ft (from Table 2)

QB-100 6.8 W/ft (from Table 2)

DT interpolation DT 60°F is 20% of the distance between DT 50°F and DT 100°F

QB-60 QB-50 + [0.20 x (QB-100 – QB-50)] = 3.2 + [0.20 x (6.8 – 3.2)] = 3.9 W/ft

Pipe heat loss (QB)3.9 W/ft @ Tm40°F (12.9 W/m @ Tm4°C)

Example: Flow Maintenance – Greasy Waste Line

Pipe diameter 4 inch

Insulation thickness 1 inch

DT 60°F (33°C)

QBfor 60°F must be calculated through interpolation between DT at 50°F and DT at 100°F

from Table 2. For difference between the DT of 50°F and the DT of 100°F:

QB-50 5.4 W/ft (from Table 2)

QB-100 11.2 W/ft (from Table 2)

DT interpolation DT 60°F is 20% of the distance between DT 50°F and DT 100°F

QB-60 QB-50 + [0.20 x (QB-100 – QB-50)] = 5.4 + [0.20 x (11.2 – 5.4)] = 6.6 W/ft

Pipe heat loss QB6.6 W/ft @ Tm110°F (21.5 W/m @ Tm43°C)

Compensate for insulation type and pipe location

The base heat loss is calculated for a pipe insulated with thermal insulation with a k-factor

ranging from 0.2 to 0.3 BTU/hr–°F-ft²/in (fiberglass or foamed elastomer) in an outdoor, or

buried application. To get the heat loss for pipes insulated with alternate types of thermal

insulation and for pipes installed indoors, multiply the base heat loss of the pipe (QB) from

Step 3 by the insulation multiple from Table 4 and the indoor multiple from Table 3 to

get the corrected heat loss:

QCORRECTED = QBx Insulation multiple x Indoor multiple

Example: Pipe Freeze Protection – Water Piping

Location Aboveground, outdoor

Thermal insulation thickness and type 1-inch fiberglass

Pipe heat loss QB3.9 W/ft @ TM40°F (12.9 W/m @ TM4°C)

QCORRECTED 3.9 W/ft x 1.00 x 1.00 = 3.9 W/ft @ Tm40°F

(12.9 W/m @ Tm4°C)

Example: Flow Maintenance – Greasy Waste Line

Location Buried

Thermal insulation type and thickness 1-inch rigid cellular urethane

Pipe heat loss QB= 6.6 W/ft @ TM110°F (21.5 W/m @ TM43°C)

QCORRECTED = 6.6 W/ft x 0.6 x 1.00 = 4.0 W/ft @ Tm110°F

(13.1 W/m @ Tm43°C)

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

16 of 44 www.tycothermal.com H55838 2/12

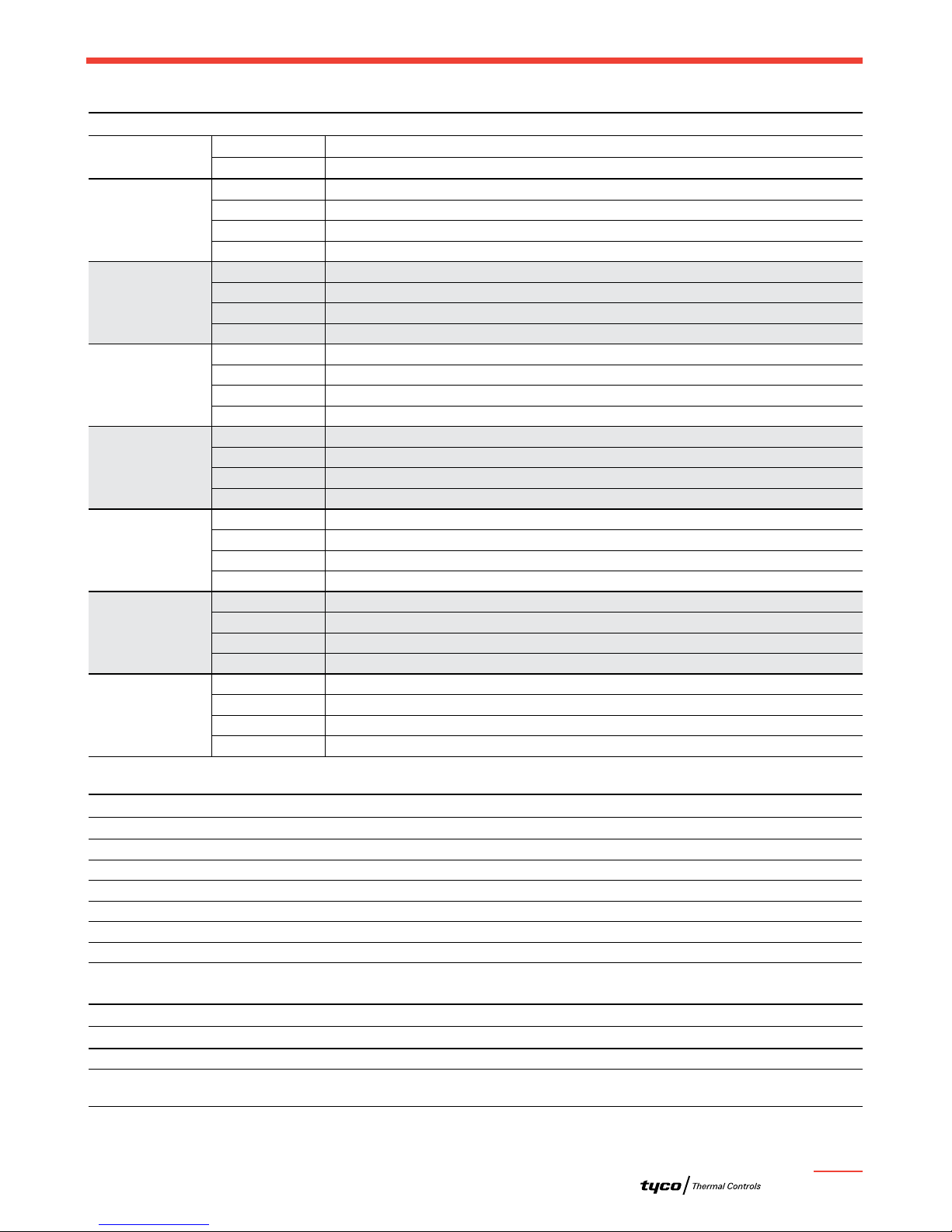

Table 2 Pipe Heat Loss (Qb) for Outdoor or Buried Pipe (W/ft) for 1/2 to 3-1/2 inches

Insulation thickness (DT) Pipe diameter (IPS) in inches

(in) °F °C 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2

0.5 20 11 1.0 1.2 1.4 1.6 1.8 2.2 2.5 3.0 3.4

50 28 2.5 2.9 3.5 4.1 4.6 5.5 6.5 7.7 8.6

100 56 5.2 6.1 7.2 8.6 9.6 11.5 13.5 16.0 18.0

150 83 8.1 9.5 11.2 13.4 14.9 17.9 21.1 25.0 28.1

1.0 20 11 0.6 0.7 0.8 1.0 1.1 1.3 1.5 1.7 1.9

50 28 1.6 1.9 2.2 2.5 2.8 3.2 3.8 4.4 4.9

100 56 3.4 3.9 4.5 5.2 5.8 6.8 7.8 9.1 10.2

150 83 5.3 6.1 7.0 8.2 9.0 10.6 12.2 14.2 15.9

1.5 20 11 0.5 0.6 0.7 0.8 0.8 1.0 1.1 1.3 1.4

50 28 1.3 1.5 1.7 1.9 2.1 2.4 2.8 3.2 3.6

100 56 2.8 3.1 3.5 4.0 4.4 5.1 5.8 6.7 7.4

150 83 4.3 4.8 5.5 6.3 6.9 8.0 9.1 10.5 11.6

2.0 20 11 0.5 0.5 0.6 0.6 0.7 0.8 0.9 1.0 1.1

50 28 1.1 1.3 1.4 1.6 1.8 2.0 2.3 2.6 2.9

100 56 2.4 2.7 3.0 3.4 3.7 4.2 4.8 5.5 6.0

150 83 3.7 4.2 4.7 5.3 5.8 6.6 7.5 8.5 9.4

2.5 20 11 0.4 0.5 0.5 0.6 0.6 0.7 0.8 0.9 1.0

50 28 1.0 1.2 1.3 1.4 1.6 1.8 2.0 2.3 2.5

100 56 2.2 2.4 2.7 3.0 3.3 3.7 4.2 4.7 5.2

150 83 3.4 3.7 4.2 4.7 5.1 5.8 6.5 7.4 8.1

3.0 20 11 0.4 0.4 0.5 0.5 0.6 0.6 0.7 0.8 0.9

50 28 1.0 1.1 1.2 1.3 1.4 1.6 1.8 2.0 2.2

100 56 2.0 2.2 2.4 2.7 2.9 3.3 3.7 4.2 4.6

150 83 3.1 3.4 3.8 4.3 4.6 5.2 5.8 6.6 7.1

4.0 20 11 0.3 0.4 0.4 0.5 0.5 0.5 0.6 0.7 0.7

50 28 0.9 0.9 1.0 1.1 1.2 1.4 1.5 1.7 1.8

100 56 1.8 2.0 2.1 2.4 2.5 2.9 3.2 3.5 3.8

150 83 2.8 3.0 3.4 3.7 4.0 4.4 4.9 5.5 6.0

Note: Multiply the W/ft heat loss values by 3.28 for W/m.

H55838 2/12 www.tycothermal.com 17 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Pipe Freeze Protection and Flow Maintenance Design

Table 1.2 continued Pipe Heat Loss (Qb) for Outdoor or Buried Pipe (W/ft) for 4 to 20 inches

Insulation thickness (DT) Pipe diameter (IPS) in inches

(in) °F °C 4 6 8 10 12 14 16 18 20

0.5 20 11 3.8 5.3 6.8 8.4 9.9 10.8 12.2 13.7 15.2

50 28 9.6 13.6 17.4 21.4 25.2 27.5 31.3 35.0 38.8

100 56 20.0 28.4 36.3 44.6 52.5 57.4 65.2 73.0 80.8

150 83 31.2 44.3 56.6 69.6 81.9 89.5 101.7 113.8 126.0

1.0 20 11 2.1 2.9 3.7 4.5 5.3 5.8 6.5 7.3 8.0

50 28 5.4 7.5 9.4 11.5 13.5 14.7 16.6 18.6 20.5

100 56 11.2 15.6 19.7 24.0 28.1 30.6 34.7 38.7 42.8

150 83 17.5 24.3 30.7 37.4 43.8 47.8 54.1 60.4 66.7

1.5 20 11 1.5 2.1 2.6 3.2 3.7 4.0 4.5 5.0 5.5

50 28 3.9 5.3 6.7 8.1 9.4 10.2 11.5 12.9 14.2

100 56 8.1 11.1 13.9 16.8 19.6 21.3 24.0 26.8 29.5

150 83 12.7 17.3 21.6 26.2 30.5 33.2 37.5 41.8 46.1

2.0 20 11 1.2 1.7 2.1 2.5 2.9 3.1 3.5 3.9 4.3

50 28 3.1 4.2 5.2 6.3 7.3 7.9 8.9 9.9 10.9

100 56 6.6 8.8 10.9 13.1 15.2 16.5 18.6 20.7 22.8

150 83 10.2 13.8 17.0 20.5 23.8 25.8 29.0 32.3 35.5

2.5 20 11 1.1 1.4 1.7 2.1 2.4 2.6 2.9 3.2 3.5

50 28 2.7 3.6 4.4 5.2 6.1 6.6 7.4 8.2 9.0

100 56 5.6 7.4 9.1 10.9 12.6 13.7 15.3 17.0 18.7

150 83 8.7 11.6 14.2 17.0 19.7 21.3 23.9 26.5 29.1

3.0 20 11 0.9 1.2 1.5 1.8 2.0 2.2 2.5 2.7 3.0

50 28 2.4 3.1 3.8 4.5 5.2 5.6 6.3 7.0 7.6

100 56 4.9 6.5 7.9 9.4 10.8 11.7 13.1 14.5 15.9

150 83 7.7 10.1 12.4 14.7 16.9 18.3 20.5 22.6 24.8

4.0 20 11 0.8 1.0 1.2 1.4 1.6 1.7 1.9 2.1 2.3

50 28 2.0 2.5 3.1 3.6 4.1 4.4 5.0 5.5 6.0

100 56 4.1 5.3 6.4 7.5 8.6 9.3 10.3 11.4 12.4

150 83 6.4 8.3 10.0 11.8 13.4 14.5 16.1 17.8 19.4

Note: Multiply the W/ft heat loss values by 3.28 for W/m.

Table 3 Indoor Pipe Heat Loss Multiples

Fiberglass thickness (in) Indooor multiple

0.5 0.79

1 0.88

1.5 0.91

2 0.93

2.5 0.94

3 0.95

4 0.97

Table 4 Insulation Heat Loss Multiples

k factor at 50°F (10°C) (BTU/hr–°F-ft²/in) Insulation multiple Examples of preformed pipe insulation

0.1–0.2 0.6 Rigid cellular urethane (ASTM C591)

0.2–0.3 1.0 Glass fiber (ASTM C547)

Foamed elastomer (ASTM C534)

0.3–0.4 1.4 Cellular glass (ASTM C552)

Mineral fiber blanket (ASTM C553)

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

18 of 44 www.tycothermal.com H55838 2/12

Pipe Freeze Protection

and Flow Maintenance

2. Select the heating

cable

3. Determine the

heating cable length

4. Determine the

electrical parameters

5. Select the

connection kits and

accessories

6. Select the control

system

7. Select the power

distribution

8. Complete the Bill of

Materials

1. Determine design

conditions and heat

loss

Step Select the heating cable

To select the appropriate XL-Trace heating cable for your application, you must determine

your cable supply voltage, power output, and outer jacket. Once you select these, you will be

able to determine the catalog number for your cable.

HEATING CABLE CATALOG NUMBER

Before beginning, take a moment to understand the structure underlying heating cable cata-

log numbers. You will refer to this numbering convention throughout the product selection

process. Your goal is to determine the catalog number for the product that best suits your

needs.

Fig. 12 Heating cable catalog number

Select the heating cable from Fig. 13 that provides the required power output to match the

corrected heat loss for your application. Fig. 13 shows the power output for the heating

cables on metal pipe at 120/208 volts. To correct the power output for other applied voltage

or plastic pipes multiply the power output at the desired maintain temperature by the factors

listed in Table 5. If the pipe heat loss, QCORRECTED, is between the two heating cable power

output curves, select the higher-rated heating cable.

5XL1-CR and 5XL1-CT (120 V)

5XL2-CR and 5XL2-CT (208 V)

8XL1-CR and 8XL1-CT (120 V)

8XL2-CR and 8XL2-CT (208 V)

12XL2-CR and 12XL2-CT (208 V)

Pipe temperature

Power W/ft

50

(10)

30

(–1)

40

(5)

60

(15)

70

(21)

80

(27)

90

(32)

100

(38)

110

(43)

120

(49)

130

(54)

°F

(°C)

10

8

14

12

6

4

2

0

Fig. 13 Heating cable power output on metal pipe

Catalog number: 5, 8 or 12 XL 1 or 2 -CR -CT

Power output (W/ft)

Product family

Voltage 1 = 120 V (only available for 5 or 8)

2 = 208, 240, 277 V (available for 5, 8, or 12)

Jacket type: Polyolefin

Fluoropolymer (required for buried pipes, grease and fuel lines)

or

H55838 2/12 www.tycothermal.com 19 of 44

2. Fire Sprinkler

System Freeze

Protection

1. Pipe Freeze

Protection and

Flow Maintenance

3. Roof and Gutter

De-Icing

4. Surface Snow

Melting – MI

5. Surface Snow

Melting and Anti-

Icing – ElectroMelt

6. Freezer Frost

Heave Prevention

7. Floor Heating 8. Technical Data

Sheets

Pipe Freeze Protection and Flow Maintenance Design

Table 5 Power Output Correction Factors

Voltage correction factors 5XL1 8XL1 5XL2 8XL2 12XL2

120 V 1.00 1.00 – – –

208 V – – 1.00 1.00 1.00

240 V – – 1.12 1.12 1.14

277 V – – 1.29 1.27 1.30

Plastic pipe correction factor

(With AT-180 Aluminum tape)

0.75 0.75 0.75 0.75 0.75

Confirm that the corrected power output of the heating cable selected is greater than the

corrected pipe heat loss (QCORRECTED). If QCORRECTED is greater than the power output of the

highest-rated heating cable, you can:

• Use two or more heating cables run in parallel

• Use thicker insulation to reduce heat loss

• Use insulation material with a lower k factor to reduce heat loss

Example: Pipe Freeze Protection – Water Piping

Pipe maintain temperature (TM) 40°F (4°C) (from Step 1)

QCORRECTED QCORRECTED = 3.9 W/ft @ TM40°F (13.1 W/m @ TM4°C)

Supply voltage 120 V (from Step 1)

Pipe material Plastic (from Step 1)

Select heating cable: QB= 3.9 W/ft @ TM40°F (from Step 1)

5XL1= 5.6 W/ft @ 40°F (from Fig. 13)

Supply voltage correction factor 1.00 (from Table 5)

Pipe material correction factor Plastic = 0.75 (from Table 5)

Corrected heating cable power 5.6 W/ft x 1.00 x 0.75 = 4.2 W/ft

Selected heating cable 5XL1

Example: Flow Maintenance – Greasy Waste Line

Pipe maintain temperature (TM) 110°F (43°C) (from Step 1)

QCORRECTED 3.9 W/ft @ TM110°F (13.1W/m @ TM43°C)

Supply voltage 208 V (from Step 1)

Pipe material Metal (from Step 1)

Select heating cable: QB= 3.9 W/ft @ TM110°F (from Step 1)

12XL2= 7.0 W/ft @110°F (from Fig. 13)

Supply voltage correction factor 1.00 (from Table 5)

Pipe material correction factor Metal = 1.00

Corrected heating cable power 7.0 x 1.00 x 1.00 = 7.0 W/ft

Selected heating cable 12XL2

PIPE FREEZE PROTECTION AND FLOW MAINTENANCE

20 of 44 www.tycothermal.com H55838 2/12

CONFIRM EXPOSURE TEMPERATURE RATING FOR THE HEATING CABLE

Refer to Table 6 to verify that the maximum system temperature does not exceed the expo-

sure temperature of the selected heating cable.

Table 6 Heating Cable Temperature Ratings

5XL1 5XL2 8XL1 8XL2 12XL2

Maximum maintain temperature (TM) 150°F

(65°C)

150°F

(65°C)

150°F

(65°C)

150°F

(65°C)

150°F

(65°C)

Maximum exposure temperature (TEXP) 150°F

(65°C)

150°F

(65°C)

150°F

(65°C)

150°F

(65°C)

185°F

(85°C)

Example: Pipe Freeze Protection – Water Piping

Maximum system temperature (TMAX) 80°F (27°C) (from Step 1)

Selected heating cable 5XL1 (from previous step)

Maximum heating cable exposure temperature (TEXP) 150°F (65°C) (from Table 6)

TMAX < TEXP Yes

Example: Flow Maintenance - Greasy Waste Line

Maximum system temperature (TMAX) 125°F (52°C) (from Step 1)

Selected heating cable 12XL2 (from previous step)

Maximum heating cable exposure temperature (TEXP) 185°F (85°C)(from Table 6

TMAX < TEXP Yes

SELECT OUTER JACKET

Select the appropriate heating cable outer jacket for the application. Jacket options are:

-CR Compatible with most XL-Trace applications

-CT Required for grease and fuel line flow maintenance; may be used in other XL-Trace

applications for improved mechanical strength and chemical resistance.

Example: Pipe Freeze Protection – Water Piping

Selection: 5XL1-CR

Example: Flow Maintenance - Greasy Waste Line

Selection: 12XL2-CT

Pipe Freeze Protection

and Flow Maintenance

2. Select the heating

cable

3. Determine the

heating cable length

4. Determine the

electrical parameters

5. Select the

connection kits and

accessories

6. Select the control

system

7. Select the power

distribution

8. Complete the Bill of

Materials

1. Determine design

conditions and heat

loss

Step Determine the heating cable length

In Step 2 you selected the appropriate heating cable and the number of runs of heating cable

required for the pipe. Multiply the length of the pipe by the number of heating cable runs for

the heating cable length.

Additional heating cable will be required for heat sinks and connection kits. Use Table 7

and Table 8 to determine the additional footage required for heat sinks (valves, flanges, and

pipe supports). You will determine the additional heating cable for connection kits in Step 5.

Round up fractional lengths to ensure heating cable lengths are sufficient.

Heating cable length = Pipe length x No. heating cable runs

Total heating cable

length required

(Pipe length x No.

heating cable runs)

Additional heating cable

for heat sinks (valves, pipe

supports, and flanges)

= +

Other manuals for XL-Trace

1

Table of contents

Other Raychem Protection Device manuals