Raychem XL-Trace User manual

XL-Trace System

InstallatIon and operatIon manual for

pIpe freeze protectIon and flow

maIntenance

THERMAL MANAGEMENT WWW.PENTAIRTHERMAL.COM

ii

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

Important Safeguards and Warnings

WARNING: FIRE AND SHOCK HAZARD.

Raychem heat-tracing systems must be installed cor-

rectly to ensure proper operation and to prevent shock

and fire. Read these important warnings and carefully

follow all the installation instructions.

•To minimize the danger of fire from sustained electrical

arcing if the heating cable is damaged or improperly

installed, and to comply with Thermal Management

requirements, agency certifications, and national elec-

trical codes, ground-fault equipment protection must

be used on each heating cable branch circuit. Arcing

may not be stopped by conventional circuit breakers.

•Approvals and performance are based on the use of

Thermal Management-specified parts only. Do not sub-

stitute parts or use vinyl electrical tape.

•Bus wires will short if they contact each other. Keep

bus wires separated.

•Connection kits and cable ends must be kept dry before

and during installation.

•The black heating cable core is conductive and can

short. It must be properly insulated and kept dry.

•Damaged bus wires can overheat or short. Do not

break bus wire strands when preparing the cable for

connection.

•Damaged heating cable can cause electrical arcing or

fire. Do not use metal attachments such as pipe straps

or tie wire. Use only Thermal Management approved

tapes and cable ties to secure the cable to the pipe.

•Do not attempt to repair or energize damaged heating

cable. Remove damaged sections at once and replace

them with a new length using the appropriate Raychem

splice kit. Replace damaged connection kits.

•Use only fire-resistant insulation materials such as

fiberglass wrap or flame-retardant foams.

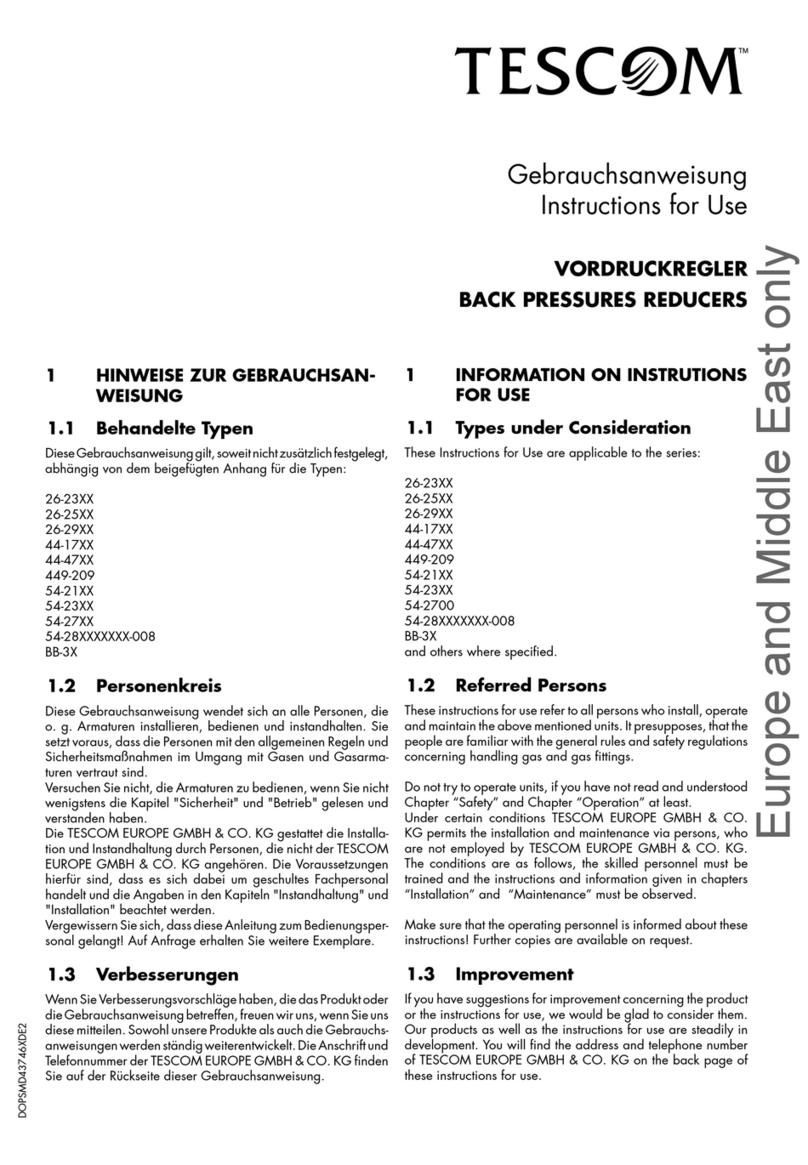

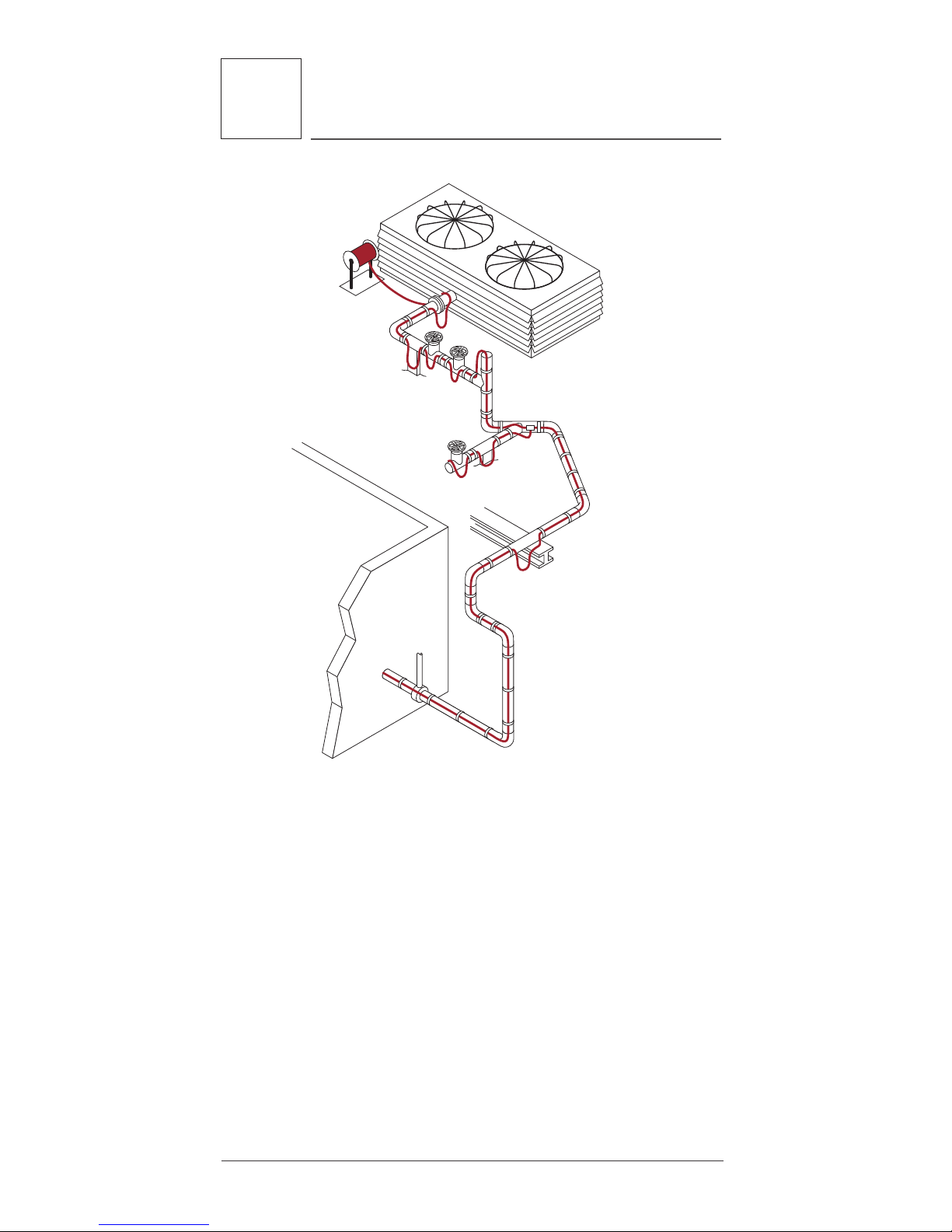

Note: Pipes are shown without insulation for illustrative

purposes only. All pipe installations must be fully cov-

ered with thermal insulation.

iii

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

Table of Contents

1 General Information 1

1.1 UseoftheManual 1

1.2 XL-TraceApplications 2

1.3 SafetyGuidelines 2

1.4 Approvals 3

2 Installation Guidelines 4

2.1 HeatingCableStorage 4

2.2 Pre-InstallationChecks 4

2.3 HeatingCableInstallation 5

2.4 HeatingCableConnections 17

3 Thermal Insulation 25

3.1 InsulatingtheSystem 25

3.2 InsulationInstallation 25

4 Power Supply and Electrical Protection 28

4.1 VoltageRating 28

4.2 CircuitBreakerSizing 28

4.3 ElectricalLoading 28

4.4 Ground-FaultProtection 28

4.5 ImportantPowerSupplySafeguards 29

5 Control, Monitoring and Power Distribution 30

5.1 ControlSystems 30

5.2 PowerDistribution 33

6 Commissioning and Preventive Maintenance 36

6.1 Tests 36

7 Test Procedures 38

7.1 SystemTests 38

7.2 FaultLocationTests 43

8 Troubleshooting Guide 48

9 Appendix 50

10 Installation and Inspection Records 56

iv

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

1

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

1

General Information

1.1 Use of the Manual

ThismanualcoverstheinstallationofRaychem

XL-Traceself-regulatingheatingcablesandcon-

nectionsforcommercialconstructionpipesystems

inordinary(nonhazardous)areas.Themanualcov-

ersgeneralheatingcableinstallationprocedures

andspecificinstallationdetailsandshowsavailable

connectionkitsforthedifferentapplications.The

manualalsodiscussescontrols,testing,andperiodic

maintenance.

Thismanualassumesthattheproperheat-tracing

designhasbeencompletedaccordingtothePipe

FreezeProtectionandFlowMaintenanceDesign

Guide(H55838).Onlytheapplicationsdescribedin

Section1.2areapprovedbyThermalManagement

forXL-Tracesystemswhenusedwithapproved

Raychemconnectionkits.Theinstructionsinthis

manualandtheinstallationinstructionsincluded

withtheconnectionkits,controlsystems,powerdis-

tributionsystems,andaccessoriesmustbefollowed

fortheThermalManagementwarrantytoapply.

ContactyourThermalManagementrepresentative

forotherapplicationsandproducts.

Foradditionalinformation,contact:

Thermal Management

7433HarwinDrive

Houston,TX77036

USA

Tel: +1.800.545.6258

Tel: +1.650.216.1526

Fax: +1.800.527.5703

Fax: +1.650.474.7711

thermal.info@pentair.com

www.pentairthermal.com

2

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

1

General Information

1.2 XL-Trace Applications

XL-Traceheat-tracingsystemsareapprovedand

qualifiedfortheapplicationslistedbelow.

Freeze protection

• General water piping.Freezeprotection(40°F

(4°C)maintain)ofinsulatedmetallicorplastic

waterpiping.

• Sprinkler piping systems.Freezeprotection(40°F

(4°C)maintain)ofinsulatedmetallicstandpipes

andsupplypipingupto20".

Flow maintenance

• Greasy waste lines.Flowmaintenance(110°F

(43°C)maintain)ofinsulated-greasedisposal

lines.

• Fuel lines.Flowmaintenance(40°F(4°C)main-

tain)forinsulatedmetallicpipingcontaining#2

fueloil.

Forheatingcableapplicationsotherthanthoselisted

above,pleaseseeyourThermalManagementrepre-

sentativeorcallusat(800)545-6258.

1.3 Safety Guidelines

Aswithanyelectricalequipment,thesafetyandreli-

abilityofanysystemdependsonthequalityofthe

productsselectedandthemannerinwhichtheyare

installedandmaintained.Incorrectdesign,handling,

installation,ormaintenanceofanyofthesystem

connectionkitscoulddamagethesystemandmay

resultininadequateperformance,overheating,

electricshock,orfire.Tominimizetheserisksand

toensurethatthesystemperformsreliably,read

andcarefullyfollowtheinformation,warnings,and

instructionsinthisguide.

Payspecialattentiontothefollowing:

• Importantinstructionsaremarked Important

• Warningsaremarked WARNING

3

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

1

General Information

1.4 Approvals

XL-Traceheat-tracingsystemscarryagency

approvalsforthedifferentapplicationsshownin

Section1.2.Fordetailedinformationonwhich

approvalsarecarriedforthespecificapplica-

tion,refertothePipeFreezeProtectionandFlow

Maintenancedesignguide(H55838).

Warranty

ThermalManagementstandardlimitedwarranty

appliestoallproducts.

Anextensionofthelimitedwarrantyperiodtoten(10)

yearsfromthedateofinstallationisavailableifa

properlycompletedonlinewarrantyformissubmit-

tedwithinthirty(30)daysfromthedateofinstalla-

tion.Youcanaccessthecompletewarrantyonour

websiteatwww.pentairthermal.com.

4

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

2.1 Heating Cable Storage

• Storetheheatingcableinaclean,drylocation.

Temperaturerange:0°F(–18°C)to140°F(60°C).

• Protecttheheatingcablefrommechanical

damage.

2.2 Pre-Installation Checks

Check materials received

Catalog number: 5, 8 or 12 XL — 1 or 2 -CR -CT

Power output (W/ft)

Product family

Voltage 1 = 120 Vac (only available for 5 or 8)

2 = 208–277 Vac (available for 5, 8, or 12)

Jacket type: Polyolefin or

Fluoropolymer

(Required for grease and fuel lines)

Figure 1: XL-Trace catalog number

• Reviewtheheatingcabledesignandcomparethe

listofmaterialstothecatalognumbersofthe

heatingcablesandconnectionkitsreceivedto

confirmthatthepropermaterialsareonsite.The

heatingcabletypeisprintedonitsjacket.

• Ensurethattheservicevoltageavailableiscorrect

fortheXL-Traceheatingcableselection.

• Inspecttheheatingcableandconnectionkitsto

ensurethereisnoin-transitdamage.

• Verifythesystemdesigndoesnotexceedthemax-

imumexposuretemperatureoftheheatingcable

5XL/8XL:150°F(65°C)12XL:185°F(85°C)

• Verifythattheheatingcablejacketsarenotdam-

agedbyconductingtheinsulationresistancetest

(refertoSection7)oneachreelofheatingcable.

Donotpowertheheatingcablewhenit’sonthe

reel.

5

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

Check piping to be traced

• Makesureallmechanicalpipetesting(i.e.hydro-

statictesting/purging)iscompleteandthesystem

hasbeenclearedbytheclientfortracing.

• Walkthesystemandplantheroutingoftheheat-

ingcableonthepipe.

• Inspectthepipingandremoveanyburrs,rough

surfaces,orsharpedges.

2.3 Heating Cable Installation

Minimuminstallationtemperatureof:0°F(–18°C).

Heatingcableinstallationinvolvesthreebasicsteps:

1. Payingouttheheatingcable

2. Attachingtheheatingcabletothepipe

3. Wrappingheatsinks

Paying out the heating cable

Mountthereelonaholderandplaceitneareither

endofthepiperuntobetraced.Useareelholder

thatpaysoutsmoothlywithlittletensionasshown

inFigure2.Avoidjerkingtheheatingcablewhile

pulling.

Payouttheheatingcableandlooselystringitalong

thepipe,makingsuretheheatingcableisalways

nexttothepipewhencrossingobstacles.Iftheheat-

ingcableisonthewrongsideofacrossingpipeor

I-beam,youwillhavetoreinstallitorcutandspliceit.

6

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

Figure 2: Paying out the heating cable

When paying out the heating cable, AVOID:

• Sharpedges

• Excessivepullingforceorjerking

• Kinkingorcrushing

• Walkingonorrunningovertheheatingcablewith

equipment

WARNING: Fire and shock hazard. Do not install

damaged heating cable. Connection kits and heat-

ing cable ends must be kept dry before and during

installation.

Attaching the heating cable

Oncetheheatingcablehasbeenrunfortheentire

section,beginfasteningittothepipe.Startatthe

endandworktowardthereel.Theadditionalheat-

ingcablerequiredforvalvesandotherheatsinksis

showninTable1andTable2.RefertoTable3forthe

additionalheatingcablerequiredforconnectionkits.

Theheatingcablemaybeinstalledinsingleorin

multiplerunsasrequiredbythedesign.

7

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

Figure 3: Attaching the heating cable

8

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

TABLE 1:

ADDITIONAL HEATING CABLE FOR VALVES

Pipe diameter (IPS)

Heating cable in feet (meters)

1/2 0.8 (0.24)

3/4 1.3 (0.4)

1 2.0 (0.6)

1-1/4 3.3 (1.1)

1-1/2 4.3 (1.3)

2 4.3 (1.3)

3 4.3 (1.3)

4 4.3 (1.3)

6 5.0 (1.5)

8 5.0 (1.5)

10 5.6 (1.7)

12 5.9 (1.9)

14 7.3 (2.2)

18 9.4 (2.9)

20 10.5 (3.2)

TABLE 2:

ADDITIONAL HEATING CABLE FOR PIPE SUPPORTS

AND FLANGES

Support

Additional heating cable

Pipehangers(insulated) Noadditionalheatingcable

Pipehangersnoninsulatedand

U-boltsupports:

Add2xpipediameter

Weldedsupportshoes Add3xthelengthoftheshoe

Flanges Add2xpipediameter

Note:Forapplicationswheremorethanoneheatingcableis

requiredperfootofpipe,thiscorrectionfactorappliesforeach

heatingcablerun.

9

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

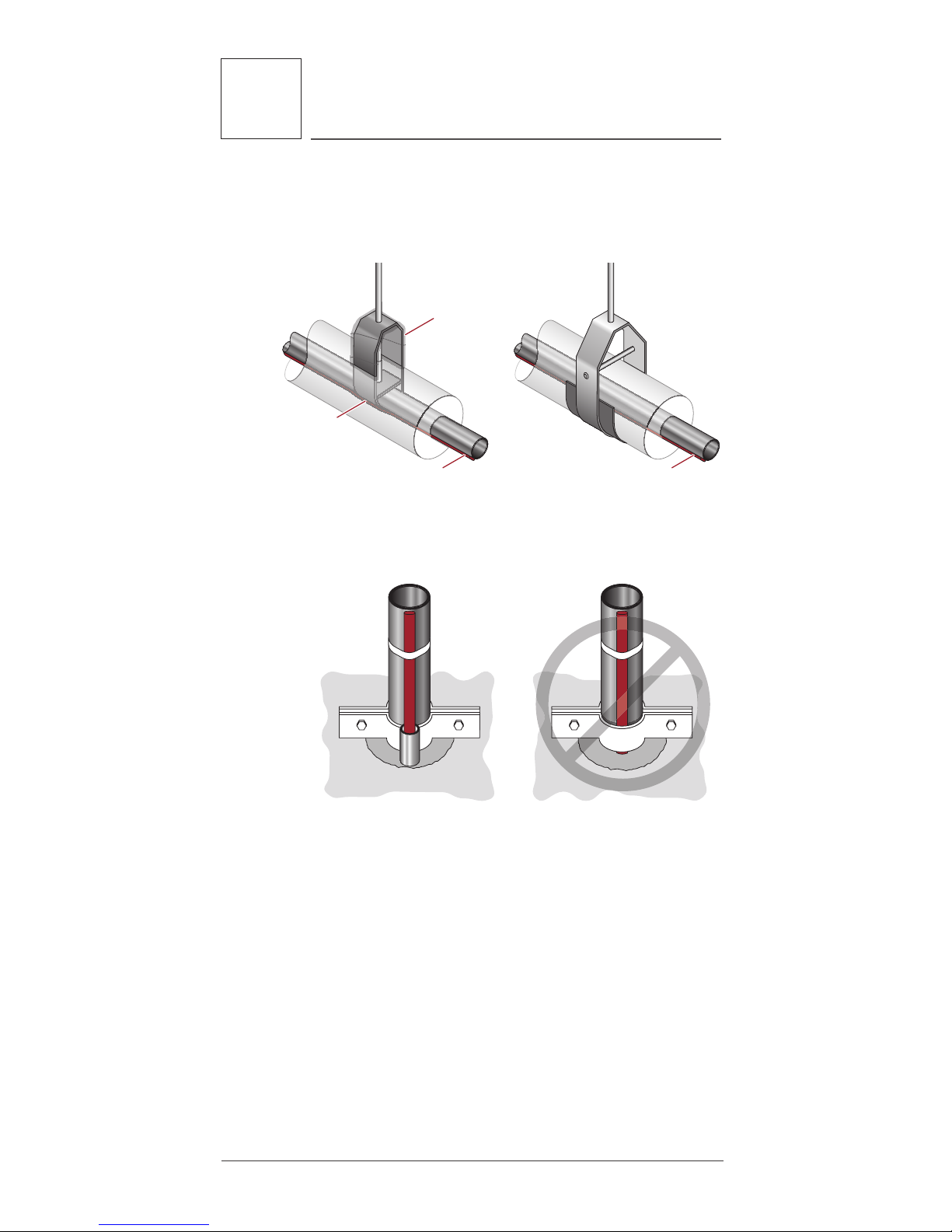

• Runinsulationthroughthepipehangerensuring

thatthepipeisnotrestingontheheater.

Heating cable

Heating cable

beneath

insulation

and pipe hanger

Heating cable

over pipe hanger

Pipe hanger

under insulation

Pipe hanger

over insulation

Insulation over

pipe hanger

Heating cable

Figure 4: Pipe hanger with heating cable

Figure 5: Single pipe floor penetration

• Whenmakingfloororwallpenetrations,make

suretheholeislargeenoughtoaccommodate

thepipeandthethermalinsulation.Whensealing

aroundpipesatfloorpenetrations,avoiddamag-

ingorcuttingtheheatingcable,orpinchingit

betweenthepipeandtheconcrete.

10

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

• Theheatingcablemustnotbeembeddeddirectly

inthesealingmaterial;thepipeshouldhavether-

malinsulationoverit(ifallowedbylocalcodes)or

theheatingcableshouldberunthroughthepene-

trationinatubeorconduit.Iftheconduitmustbe

sealed,useapliablefire-resistantmaterial(Dow

CorningFireStop,3MFireBarrier,orT&BFlame-

Safe)thatcanberemovedifnecessary.

Figure 6: Multiple pipe floor penetration

• Onverticalpipinggroups,runtheheatingcable

alongtheinsideofthepipeclosetootherpipes

soitwillnotbedamagedifthepipehitstheside

ofthefloorpenetration.Runtheheatingcable

overtheoutsideofthepipesupport.Donot

clamptheheatingcabletothepipewiththepipe

support.

• Inhigh-riseconstructionitmaybenecessaryto

installtheXL-Tracesystem10or12floorsata

timetofitintotheconstructionschedule.Ifso,

theendoftheheatingcableshouldbesealedwith

aRayClic-Eendsealandplacedinanaccessible

location.Thisallowstestingofonepartofthe

heatingcableatatime,andallowssplicingitto

anothersectionwhenthesystemiscomplete.

• WhenXL-Traceisinstalledbehindwalls,the

powerconnectionkitmustbeaccessible.

Wheneverpossible,positiontheheatingcableon

thelowersectionofthepipeasshowninFigure7to

protectitfromdamage.

11

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

One heating cable

45°

Two heating cables

45° 45°

Figure 7: Positioning the heating cable

Securing the heating cable

WARNING: Damage to the heating cable can

cause electrical arcing or fire. Do not use metal

attachments such as pipe straps or tie wire. Use only

Thermal Management-approved tapes or plastic

cable ties.

Important: Before taping the heating cable to

the pipe, make sure all heat-tracing allowances for

flanges, valves, supports, and other connection kits

have been verified.

Useoneofthefollowingattachmentmethodsto

securetheheatingcableontothepipe:GT-66or

GS-54glassclothtape,AT-180aluminumtape,or

plasticcableties.

Glass clotH adHesiVe tape

• GT-66(66-footroll)general-purposetapefor

installationat40°F(4°C)andabove.Applyat

1-footintervals.

• GS-54(54-footroll)general-purposetapefor

installationbelow40°F(4°C).Applyat1-foot

intervals.

at-180

aluMinuM tape

• Requiredforplasticpipeapplicationstoensure

properpoweroutputofheatingcable.

12 Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

• Tapelengthwiseovertheheatingcableas

requiredbythedesigndrawingorspecification

(seeFigure8).

• Recommendedforheat-tracingpumpbodiesor

odd-shapedequipment,orascalledoutinthe

designdrawingasaheat-transferaid.

• Installattemperaturesabove32°F(0°C).

Heating cable

1 ft (0.3 m)

Pipe

Thermal insulation

Weather proofing

Glass cloth tape

AT-180 aluminum tape

over heating cable

(Required for proper

output for plastic

pipe applications)

Heating

cable

PipeAT-180

aluminum tape

Figure 8: Attaching the heating cable

ca Ble ties

• Recommendedinapplicationswherethepipesur-

facepreventspropertapeadhesion.

• Useplasticcabletiesonly.

• Cabletiesmustbehand-tightenedonlytoprevent

damagetoheatingcable!

Bending/Crossing/Cutting the Heating Cable

BendinG tH e HeatinG caBle

Whenpositioningtheheatingcableonthepipe,do

notbendtighterthan1/2"radius.Theheatingcable

doesnotbendeasilyintheflatplane.Donotforce

suchabend,astheheatingcablewillbedamaged.

13

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

1/2"

Figure 9: Bending technique

crossin G tHe HeatinG caBle

XL-Traceheatingcablesareself-regulatingandmay

beoverlappedwhenevernecessarywithoutover-

heatingorburningout.

cuttinG tH e HeatinG caBle

Cuttheheatingcabletothedesiredlengthafteritis

attachedtothepipe.XL-Tracecanbecuttolength

withoutaffectingtheheatoutputperfoot.

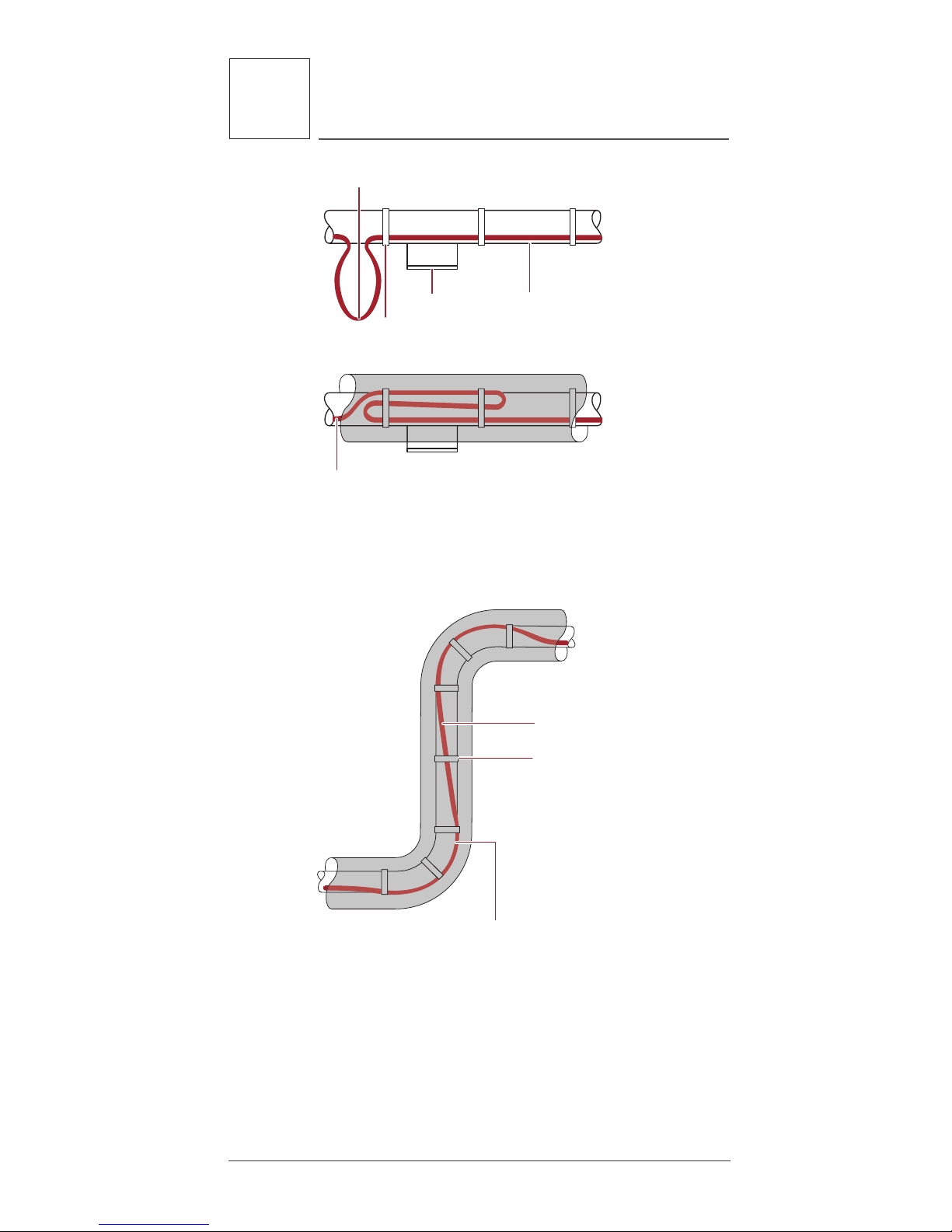

Wrapping the Heat Sinks

Oncethestraightsectionsaresecuredtheheating

cablecanbesecuredtotheheatsinks.Attachthe

heatingcabletotheheatsinksaccordingtoFigure

10below.Thelengthofheatingcableinstalledis

determinedinthedesign.

14 Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

Valve body

Multiple crossovers allowed

for self-regulating cables

Single crossover only, allowed

for power-limiting cables

Glass tape Pipe

Heating cable

Pipe

Heating cable

Note: Cable loop length

varies depending on

heat loss.

Figure 10: Valve

Glass tape

(typical)

Heating cable Loop length is twice

the diameter of the pipe

Figure 11: Flange

15

Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

Heating cable

Glass tape

Pipe

Figure 12: Pressure gauge

Glass tape

Pump discharge

Pump body

Heating cable

Pump

suction

Use AT-180

tape

Motor

To power connection

Pump body

Pump body

Figure 13: Split case centrifugal pump

16 Raychem-IM-H58033-XLTracePipeFreezeProtectionCOM-EN 18/01

2

Installation Guidelines

Heating cable secured to pipe

Glass tape

Heating cable loop

Support shoe Pipe

Figure 14: Pipe support shoe

Heating cable

Glass tape

(typical)

For pipe diameters of 2"

and larger, the heating

cable should be installed

on the outside (long)

radius of the elbow.

Figure 15: Elbow

Other manuals for XL-Trace

1

Table of contents

Other Raychem Protection Device manuals