Content

1 Safety Instructions .................................................................................................8

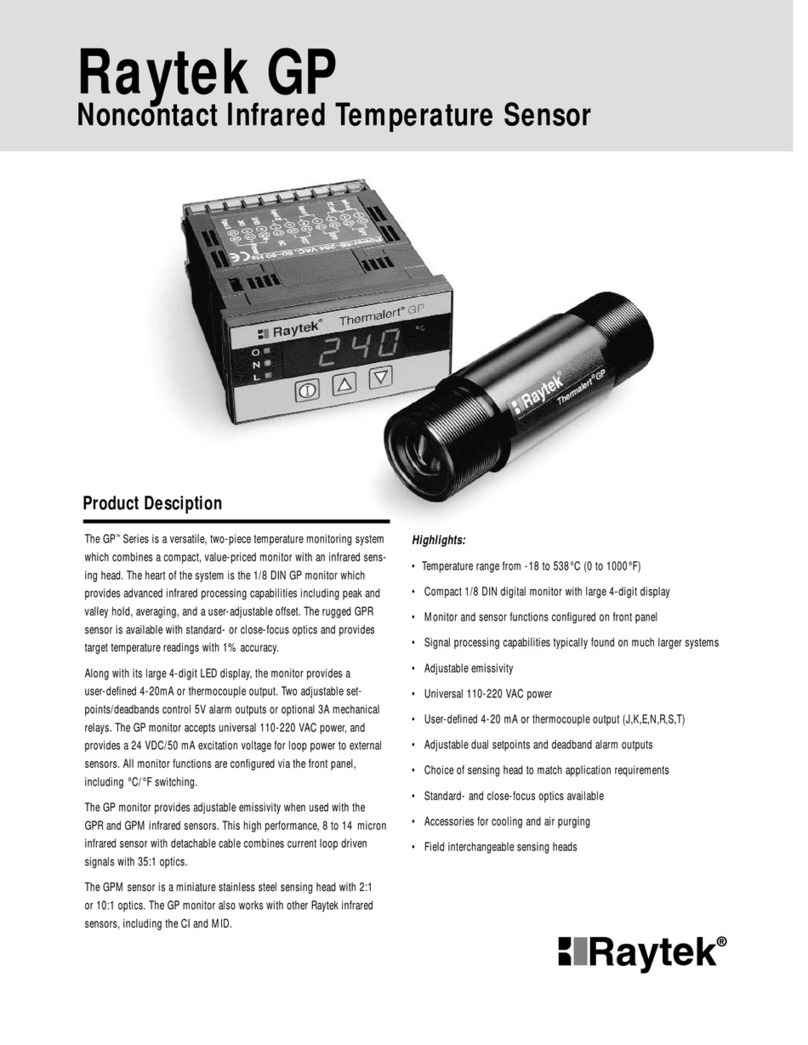

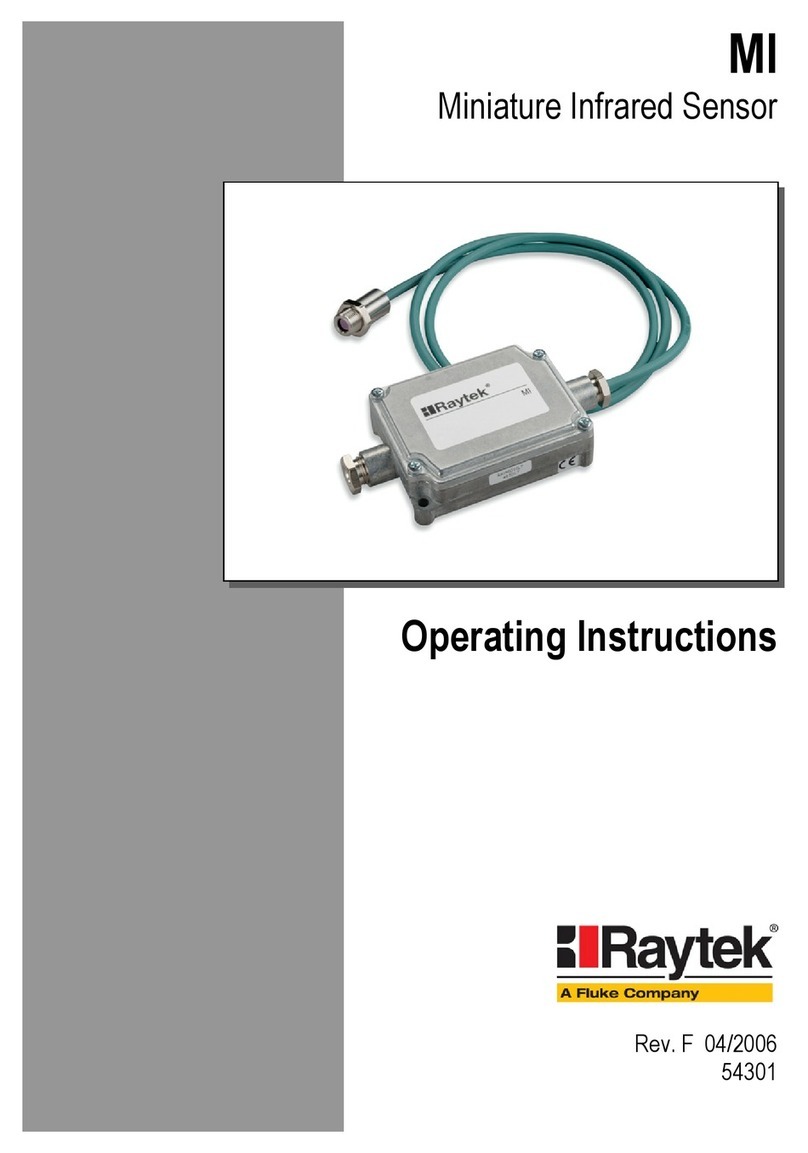

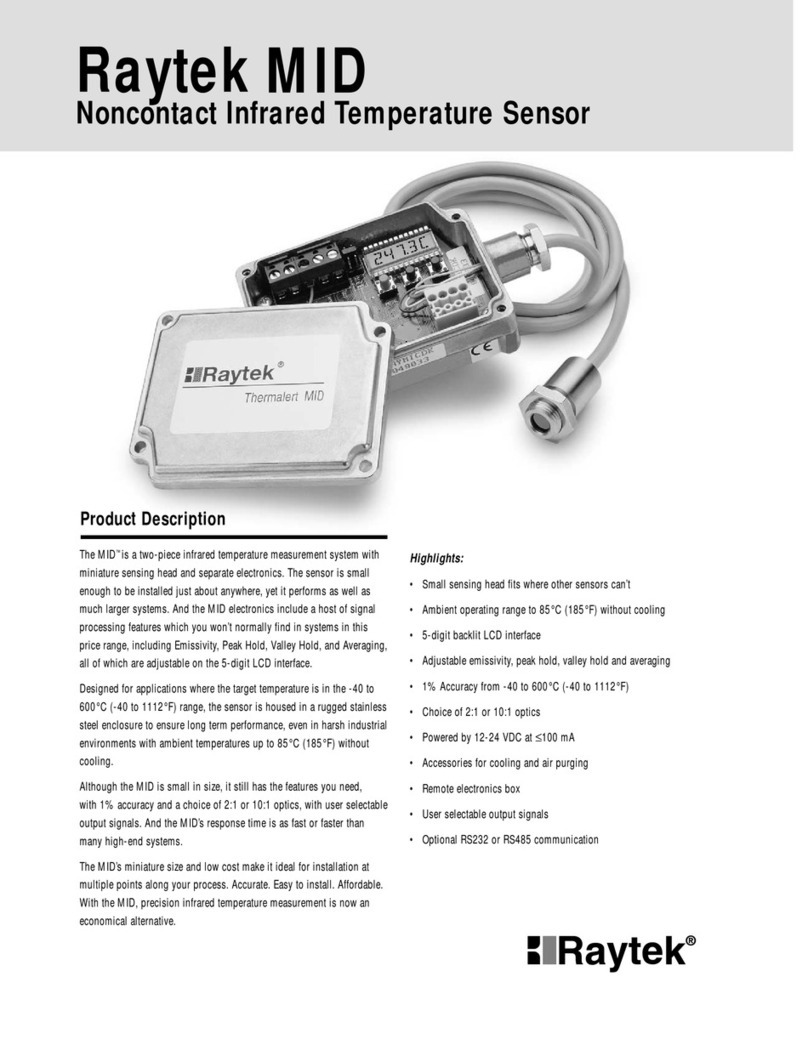

2 Description............................................................................................................10

3 Technical Data ......................................................................................................11

3.1 PARAMETERS....................................................................................................11

3.2 OPTICAL DIAGRAM..........................................................................................13

3.3 SCOPE OF DELIVERY.........................................................................................14

4 Basics ......................................................................................................................15

4.1 MEASUREMENT OF INFRARED TEMPERATURE ................................................15

4.2 DISTANCE AND SPOT SIZE ...............................................................................16

4.3 AMBIENT TEMPERATURE .................................................................................16

4.4 ATMOSPHERIC QUALITY..................................................................................16

4.5 ELECTRICAL INTERFERENCE ............................................................................17

4.6 EMISSIVITY OF TARGET OBJECT .......................................................................17

5 Install and Operation ..........................................................................................18

5.1 DIMENSIONS OF SENSOR..................................................................................18

5.2 MECHANICAL INSTALLATION .........................................................................19

5.3 CABLE...............................................................................................................19

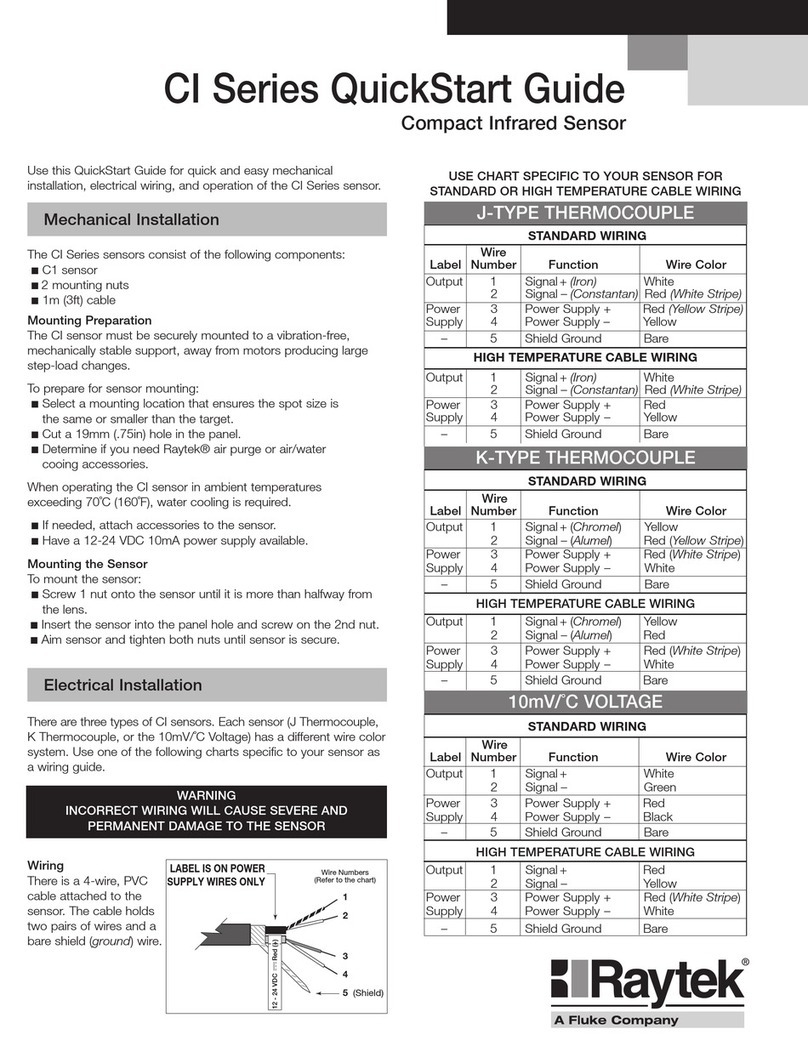

5.4 WIRE CONNECTION .........................................................................................20

5.4.1 Analog output ...........................................................................................20

5.4.2 Alarm output.............................................................................................20

5.5 LED INDICATOR AND BLINK MODE.................................................................21

6 Software .................................................................................................................22

7 Accessories ............................................................................................................23

7.1 OVERVIEW........................................................................................................23

7.2 FIXED MOUNTING BRACKET............................................................................24

7.3 ADJUSTABLE MOUNTING BRACKET ................................................................25

7.4 AIR PURGE COLLAR.........................................................................................26

7.5 RIGHT ANGLE MIRROR....................................................................................27

7.6 PROTECTIVE WINDOW.....................................................................................28

8 Programming ........................................................................................................29

8.1 GENERAL COMMAND STRUCTURE ..................................................................29

8.2 DEVICE SETUP ..................................................................................................30

8.2.1 Temperature Calculation...........................................................................30

8.2.2 Post Processing .........................................................................................30