THANK YOU

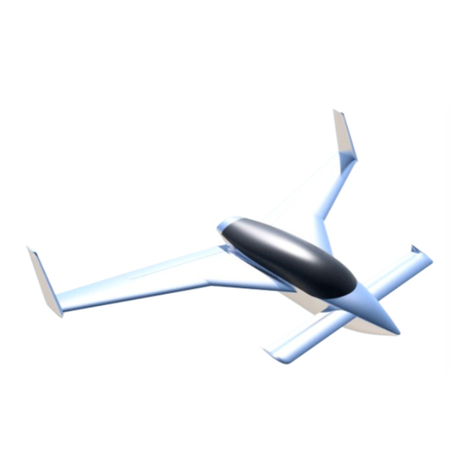

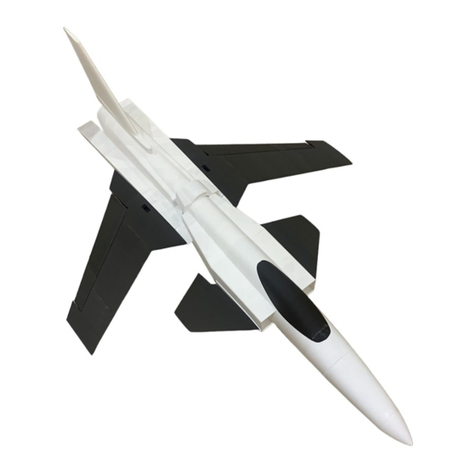

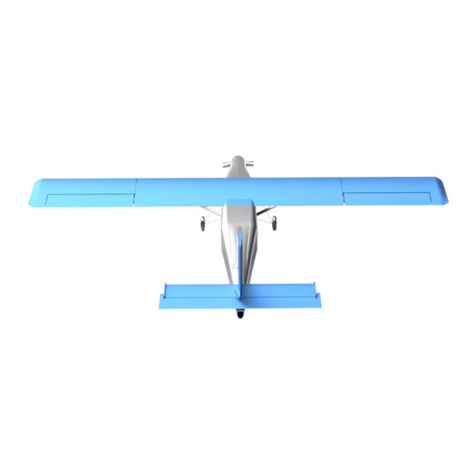

Thank you for downloading this Micro Peregrine flying wing. These models take many hours

of work to make available to you so please don’t share the STL files with others. Send them

to www.rc3print.com where they can download the models themselves. This enables me to

continue to develop new models to make them available for download.

This document aims to help you print and assemble your aircraft. Our designs are made to

be simple, this model is designed explicitly with LW-PLA in mind, so it incorporates carbon

tube spars. If you print it from regular PLA it will obviously be heavier and you should take

this into account.

3D printers often have many differences so you may need to tweak settings to get the best

results.

Included in the document you will find Cura profiles and layouts for each part and assembly

instructions. Most of the components in the design are solid bodies, this has some advantages

over hollow bodies in that you can adjust some settings such as wall thickness, infill

percentage, etc. As such we recommend using Cura to slice the files though it is not

required for this model. The walls of these solid bodies are single line 0.4mm thickness to

reduce weight. As you are printing and assembling the model yourself we take no liability

for damage or loss resulting from your use of these files. Please fly responsibly and follow all

local laws.

Share your results on Instagram, Facebook, or by email and tag @rc3dprint for discount

codes on future orders.