2

Contents of the Strega Manual

Introduction......................................................................................................................................................... 2

Materials needed................................................................................................................................................. 3

Strega-Kit......................................................................................................................................................... 3

Additional materials required......................................................................................................................... 3

A few added and some replaced parts............................................................................................................4

Preparations and assembly of parts:................................................................................................................... 4

Sanding the sealing lips................................................................................................................................... 4

Installation of control horns in the wings....................................................................................................... 5

Installation of the wing servos........................................................................................................................ 7

(Making and) mounting the servo board...................................................................................................... 16

V-Tail linkage................................................................................................................................................. 18

Ballast tube....................................................................................................................................................19

Setup of the plane.............................................................................................................................................. 21

Flying Strega...................................................................................................................................................... 23

Introduction

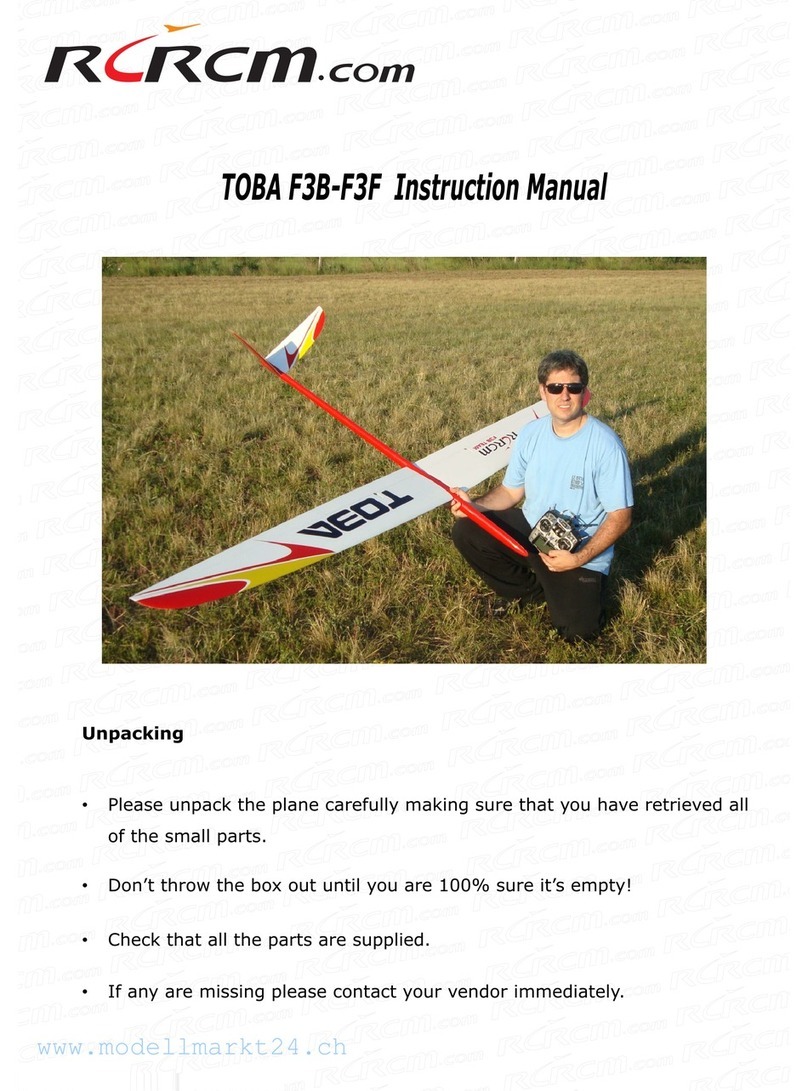

The RC glider Strega from RCRCM is a full on F3F/F3B sports model. It is ideal for the ambitioned RC

amateur pilot who wants a high end all-round glider that features excellent thermal flying- but also

speed flying- capabilities. In addition, the Strega cuts through hard transitions smoothly and will also

promptly follow your commands through basic aerobatic maneuvers.

I prepared this assembly guide for the medium experienced craftsman. Therefore, I have

described all assembly steps that I deem critical for proper function of the plane. Knowledge of

standard techniques such as use of epoxy resin, soldering cables and plugs, as well as

preparation/choice of batteries and RC equipment, is required. In a few cases I used materials that

are not supplied with the kit. There, more detailed explanations- as well as the reasons for the

changes- are given. I actually really enjoyed the building process of the Strega and, I wish you a lot of

fun building it yourself! At the end of this guide there will also be a section on the RC-setup of the

plane and on flying it.