1. Adopt PID Program-controlled temperature control technology, rapid

temperature rise, stable temperature and small error.

2. The air volume is adjustable and can be adjusted to a small soft air volume,

especially suitable for the small components of the de-soldering patch to

prevent unnecessary troubles by blowing small components.

3. The handle is light and easy to operate.

4. LCD liquid crystal display, the display can adjust the direction up and down, it

looks very delicately made.

5. The machine design has the following user-friendly functions:

A. Temperature Celsius/Fahrenheit display function:

This temperature display mode designed to meet the needs of different

markets, you can choose according to your customary or interest.

B. Air gun automatic/manual function:

a. When you choose the Auto function, and the air gun handle back on the

bracket, the machine will shut off the heater automatically and cool down, it

can prolong the service life of the heating element effectively and it is energy

saving and environment friendly. It has very high safe factors when turn on the

machine again, when you turn on the machine at an unknown condition. It can

prevent the fire or other accidents effectively.

the air gun will not cool down b. When you choose the manual function,

when you put it back to bracket, this function is suitable for using the air gun

frequently, it can save the cooling and warming up time, improve the working

efficiency. We recommend you that after using the manual function, please

transfer the function into auto function, so it can improve the safety.

C. Digital temperature correction function:

You can use this feature to correct the temperature when the iron temperature

is different from the display temperature, which caused by the environmental

impact or replacing heating element, iron tips or other components.

D. One button for Cold/Hot Air Switch:

Pressing the regulator enables switching between cold and hot air. At this point,

the air gun heating wire stops heating, and the air pump is used for air supply,

enabling the user to cool down the heating elements.

E. CH1/CH2/CH3 three-stage preset storage function:

The user can preset the temperature of each storage section according to the

requirements. In the soldering work, the user can quickly adjust the preset

values of CH1/CH2/CH3 according to different welding environments.

6. The internal use of SMT double technology, the component is neatly, the signal

flow is clearly, the reliability and safety is further improved thus can suitable for

any kind of bad condition.

7. Anti-static design to prevent static or leakage damage to components.

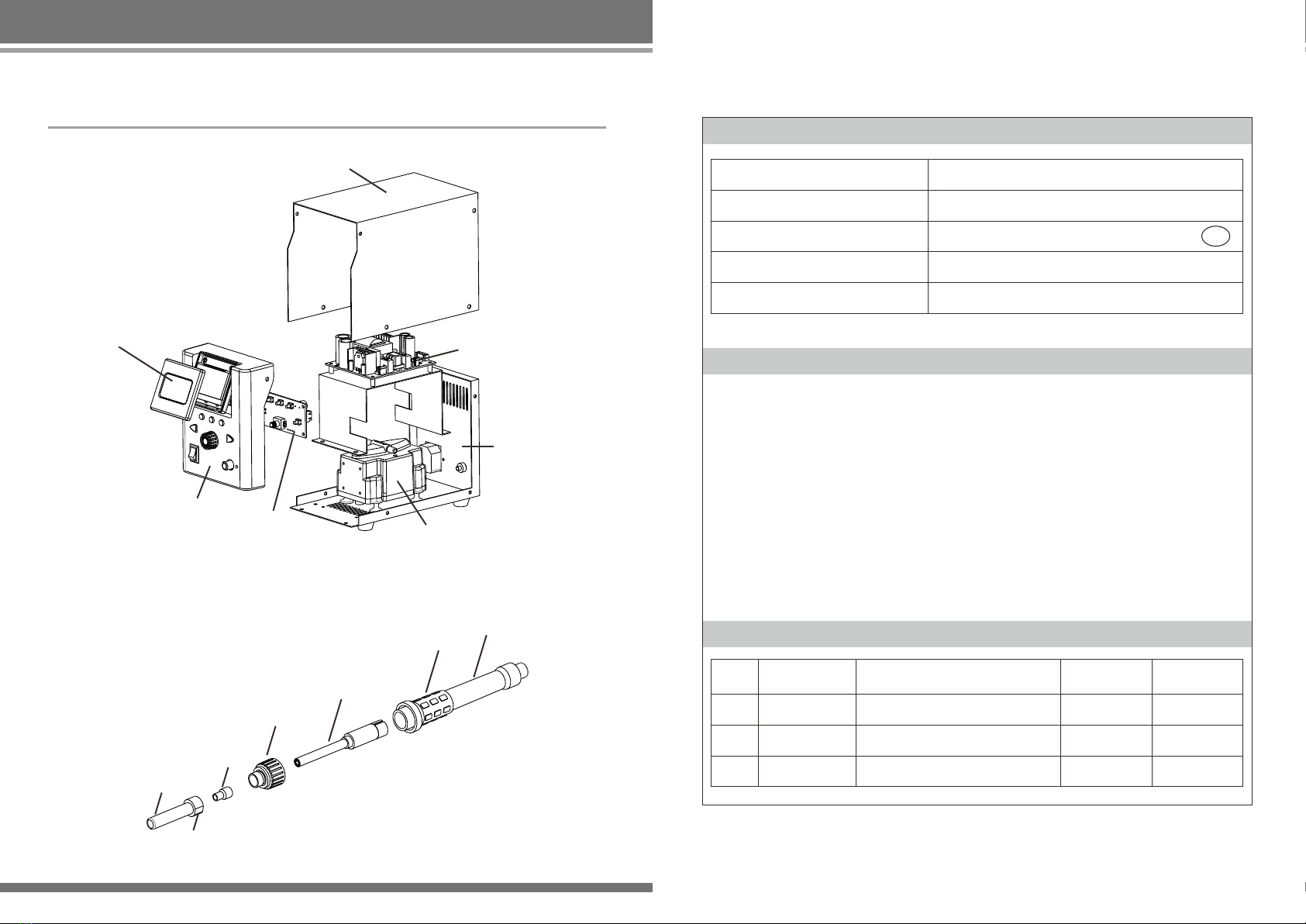

I. Products Feature

1 2

To use this product, the following basic measures should be strictly followed to

avoid hazards of electric shock, bodily injury, and fire.

1. To ensure personal safety, please turn off the power switch after power

work is completed; if it will not be used for a long time, please unplug the

power cord!!!

2. Serious consequences may result if non-original or non-approved parts are

used.

3. In the event of product failure, repairs must be carried out by professionals or

manufacturer-designated personnel.

4. This product uses three-wire grounded plug must be inserted into three- hole

grounded outlet, do not change the plug or use an ungrounded three-headed

adapter leaving poor grounding.

5. After the de-soldering station is switched on, its temperature can exceed

400°C. Do not use near flammable or explosive objects. To avoid burns, do not

touch the metal part of the soldering iron.

6. Do not leave the work area when the soldering station is switched on.

7. The power cord must be unplugged and the iron must be allowed to cool before

installing or replacing soldering iron parts.

8. After used, remember that cooling the unit before installation.

9. Soldering produces fumes, ensure there is adequate ventilation.

Safety Guidelines

1. If the power cord is damaged, it must be replaced by a specialist in the

manufacturer or service department to avoid danger.

2. This tool must be placed on its stand when not in use.

3. Be careful when using the appliance in places where there are combustible

materials; Do not use this appliance in the same place for a long time.

4. Be aware that heat may be conducted to combustible materials that are out of

sight; Do not leave the appliance unattended when it is switched on.

5. This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge. Unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should

be supervised to ensure that they do not play with the appliance.

Warning!!!