浙江热刺激光技术有限公司

Zhejiang Reci Laser Technology Co., Ltd.

- 1 -

Content

Chapter 1 Product Introduction ............................................................................................ - 3 -

1.1 General Information ................................................................................................. - 3 -

1.2 Description ................................................................................................................ - 3 -

Chapter 2 Specifications ....................................................................................................... - 3 -

2.1 Laser System Specification ...................................................................................... - 3 -

2.2 Integrated RF Power Supply Specification .............................................................. - 4 -

2.3 DC Power Supply Specification ............................................................................... - 4 -

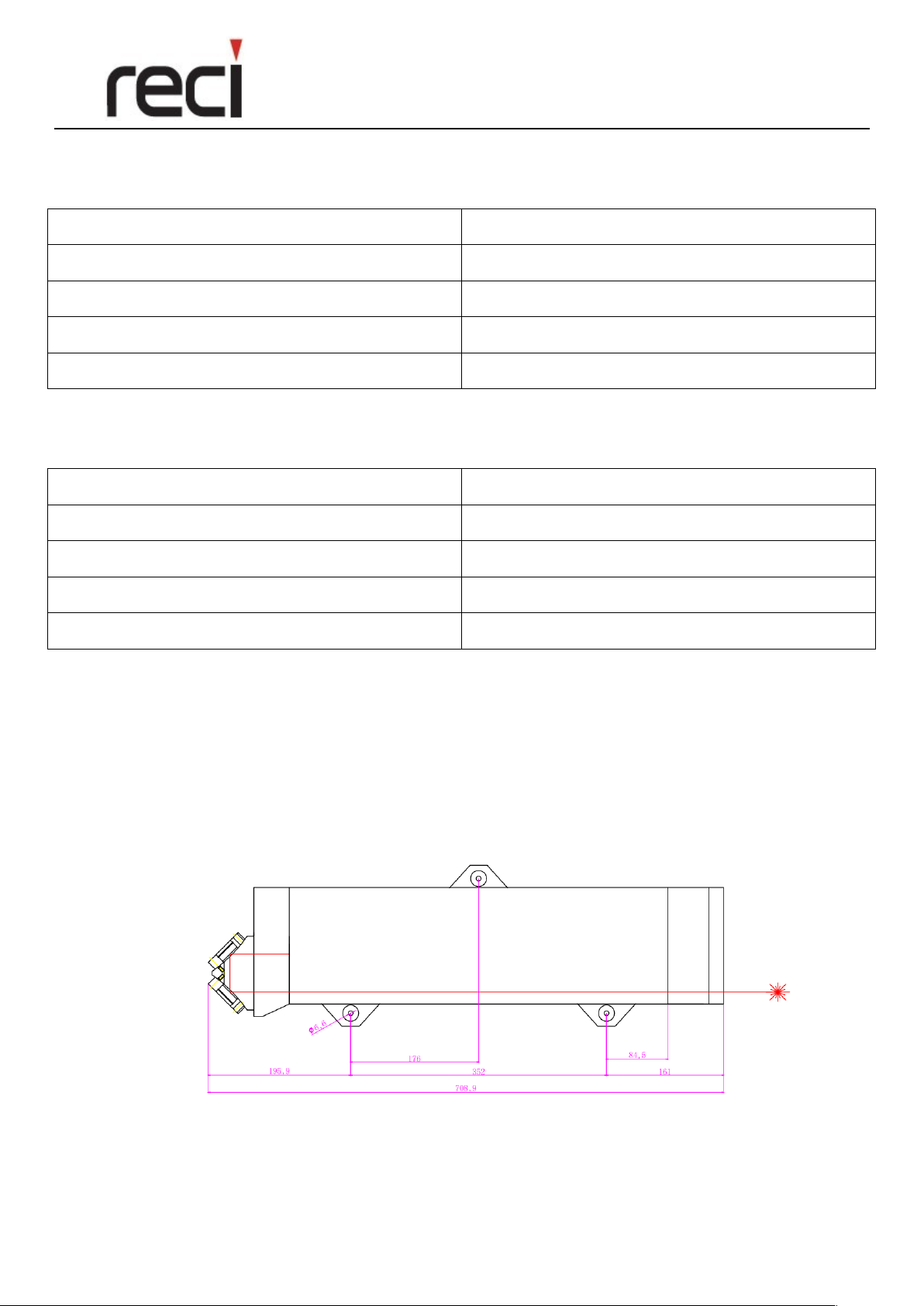

2.4 Fixing locations ........................................................................................................ - 4 -

2.5 Technical Information ............................................................................................... - 5 -

2.6 Environmental Specification .................................................................................... - 5 -

2.7 Coolant Specification ............................................................................................... - 5 -

2.8 Nitrogen Specification .............................................................................................. - 7 -

Chapter 3 The Installation .................................................................................................... - 8 -

3.1 Installation ................................................................................................................ - 8 -

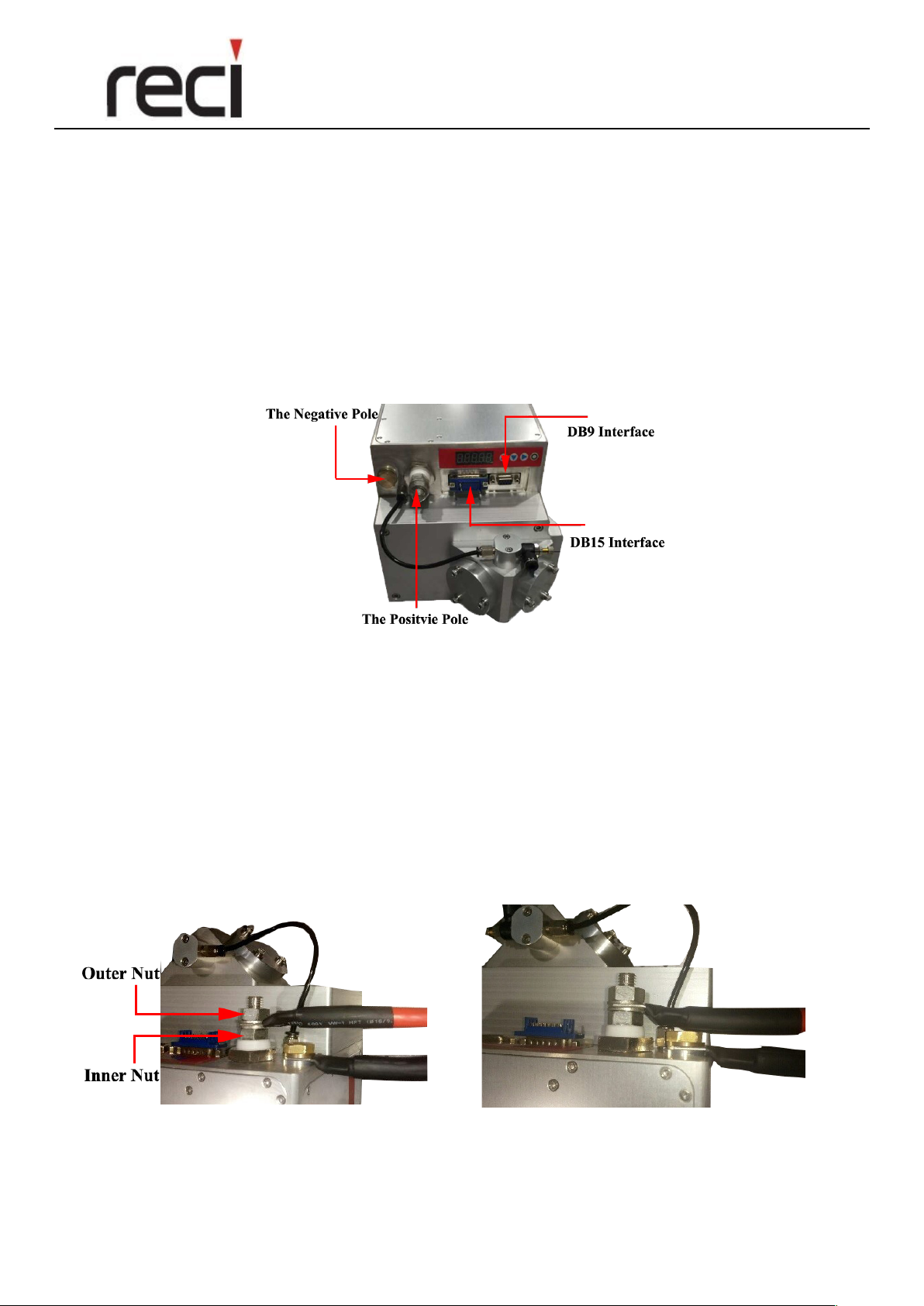

Chapter 4 Pin Connection Description ............................................................................... - 10 -

4.1 Communication Interface ....................................................................................... - 10 -

4.2 Functions Reequipment .......................................................................................... - 11 -

4.3 Common Problem ................................................................................................... - 11 -

4.4 Serial Port Specification ......................................................................................... - 12 -

Chapter 5 Operating Instruction ......................................................................................... - 15 -