Beijing Reci Laser Technology Co., Ltd

User Guide for FCA Series Hand Laser Welding System

CONTENT

Chapter 1 Safety Information............................................................................................................... 3

1.1 Safety Conventions used in the User Guide............................................................................ 3

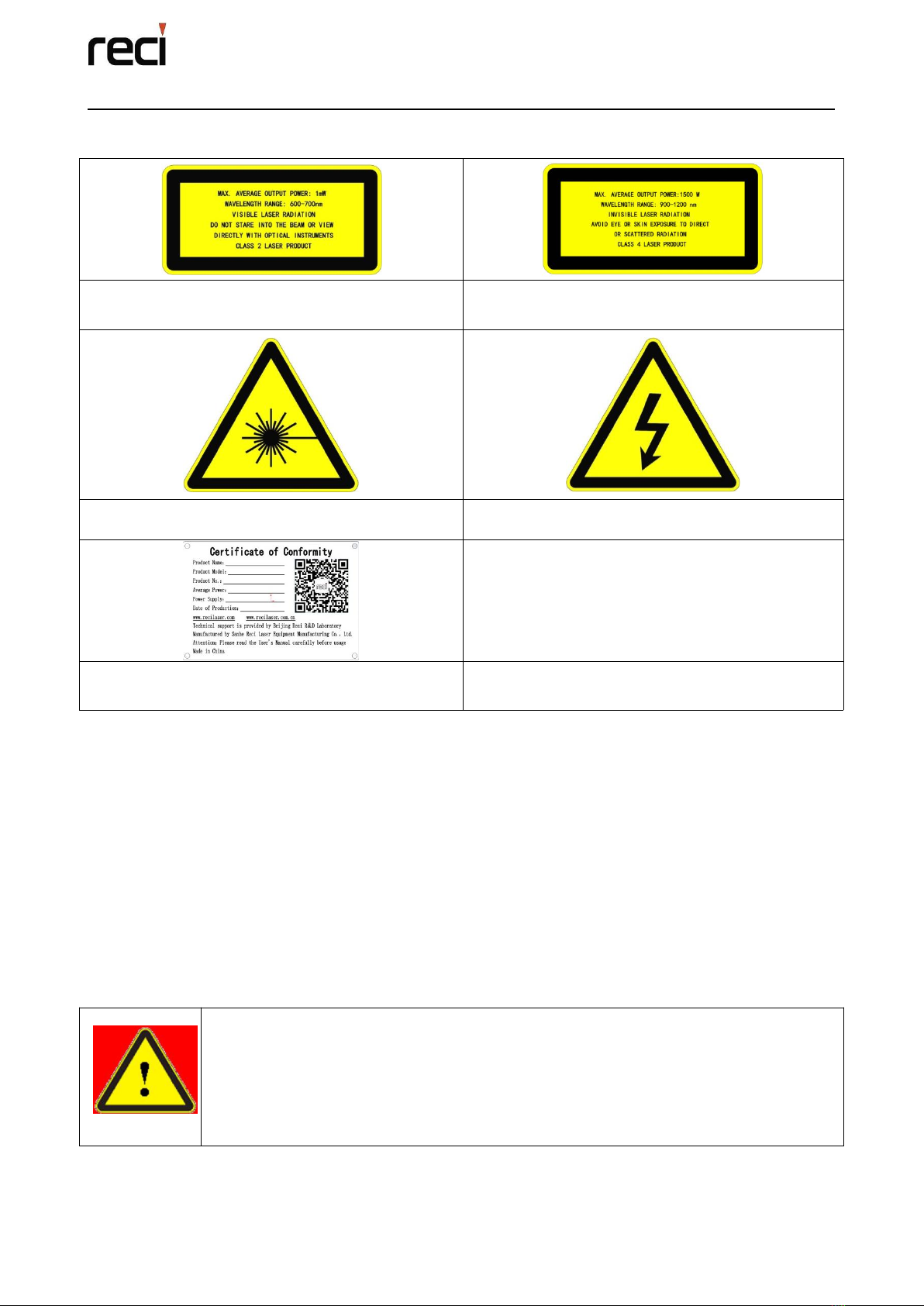

1.2 Laser Classification..................................................................................................................3

1.3 Labels on the Product.............................................................................................................. 4

1.4 Safety Instructions for Optical Operation................................................................................5

1.5 Safety Instructions for Electrical Operation............................................................................ 6

1.6 Other Safety Instructions......................................................................................................... 7

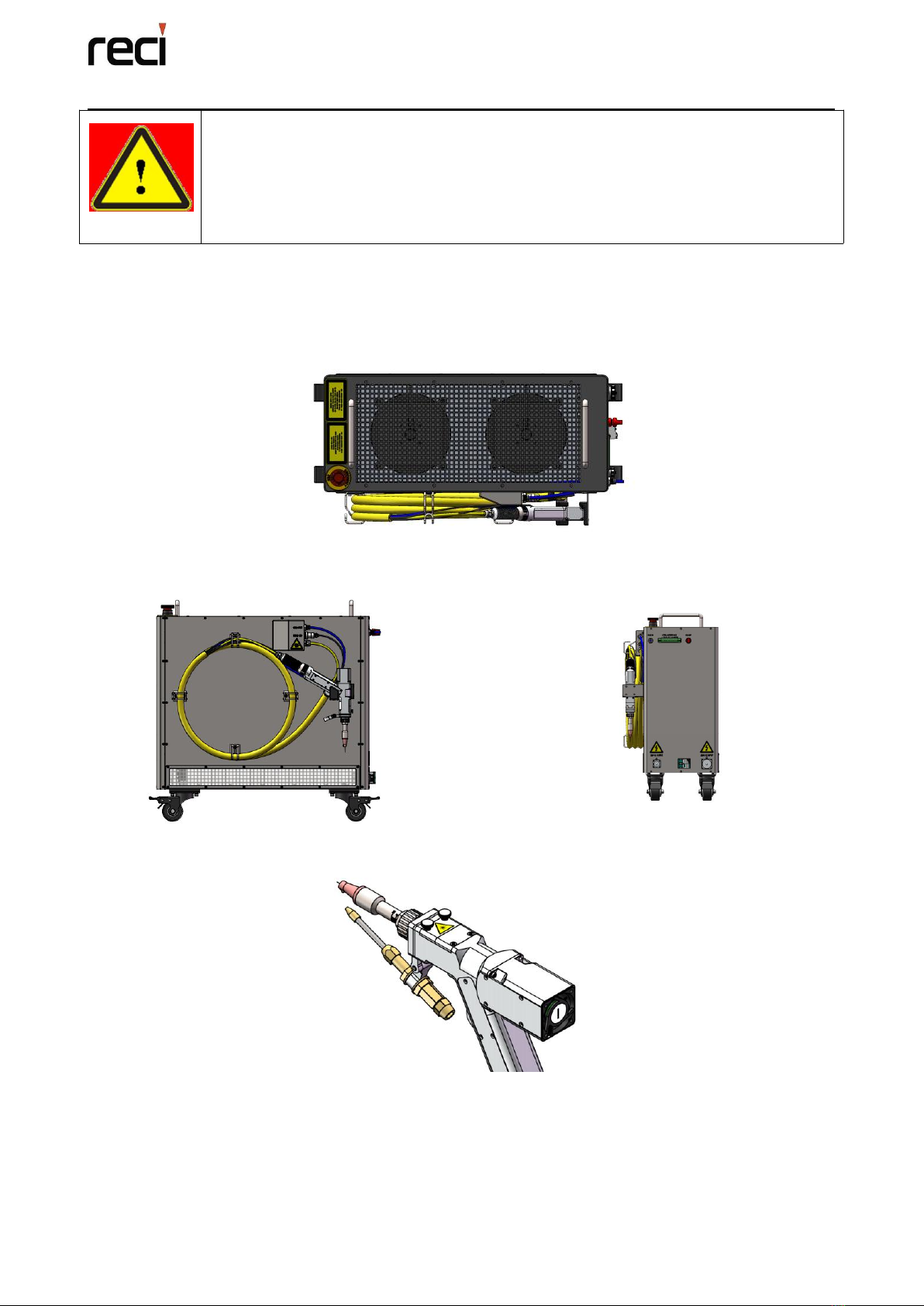

Chapter 2 Product Description............................................................................................................. 8

2.1 Property Introductions............................................................................................................. 8

2.2 Model description.................................................................................................................... 8

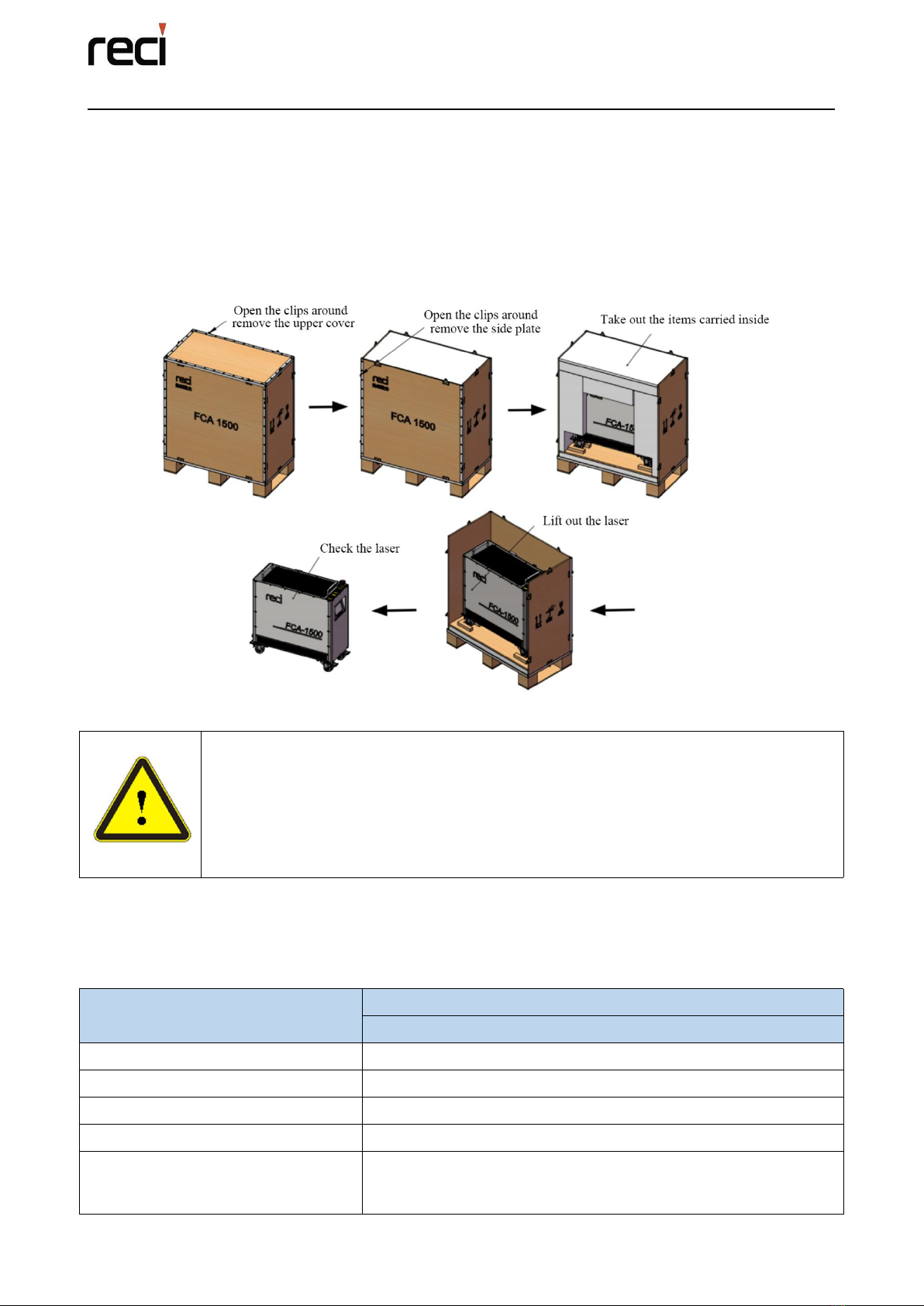

2.3 Unpacking and inspection........................................................................................................8

2.4 Operation Conditions...............................................................................................................9

2.5 Instructions for use.................................................................................................................10

2.6 Characteristic Parameters.......................................................................................................10

Chapter 3 Installation of the laser.......................................................................................................12

3.1 Dimension of the machine..................................................................................................... 12

3.2 The optical output head..........................................................................................................12

3.3 Connection and Requirements............................................................................................... 13

3.3.1 Connection of external circuit and air circuit..................................................................... 13

3.3.2 Requirement of the cooling system.................................................................................... 14

3.4 Installation precautions.......................................................................................................... 14

Chapter 4 Using of the product.......................................................................................................... 16

4.1 Front Panel.............................................................................................................................16

4.2 Rear Panel.............................................................................................................................. 18

4.3 Electric Power Connect......................................................................................................... 19

4.4 Interface Definition................................................................................................................20

4.5 Laser Control......................................................................................................................... 21

4.6 Touch screen Mode................................................................................................................ 22

4.6.1 Settings and Connections....................................................................................................22