Operating Notes:

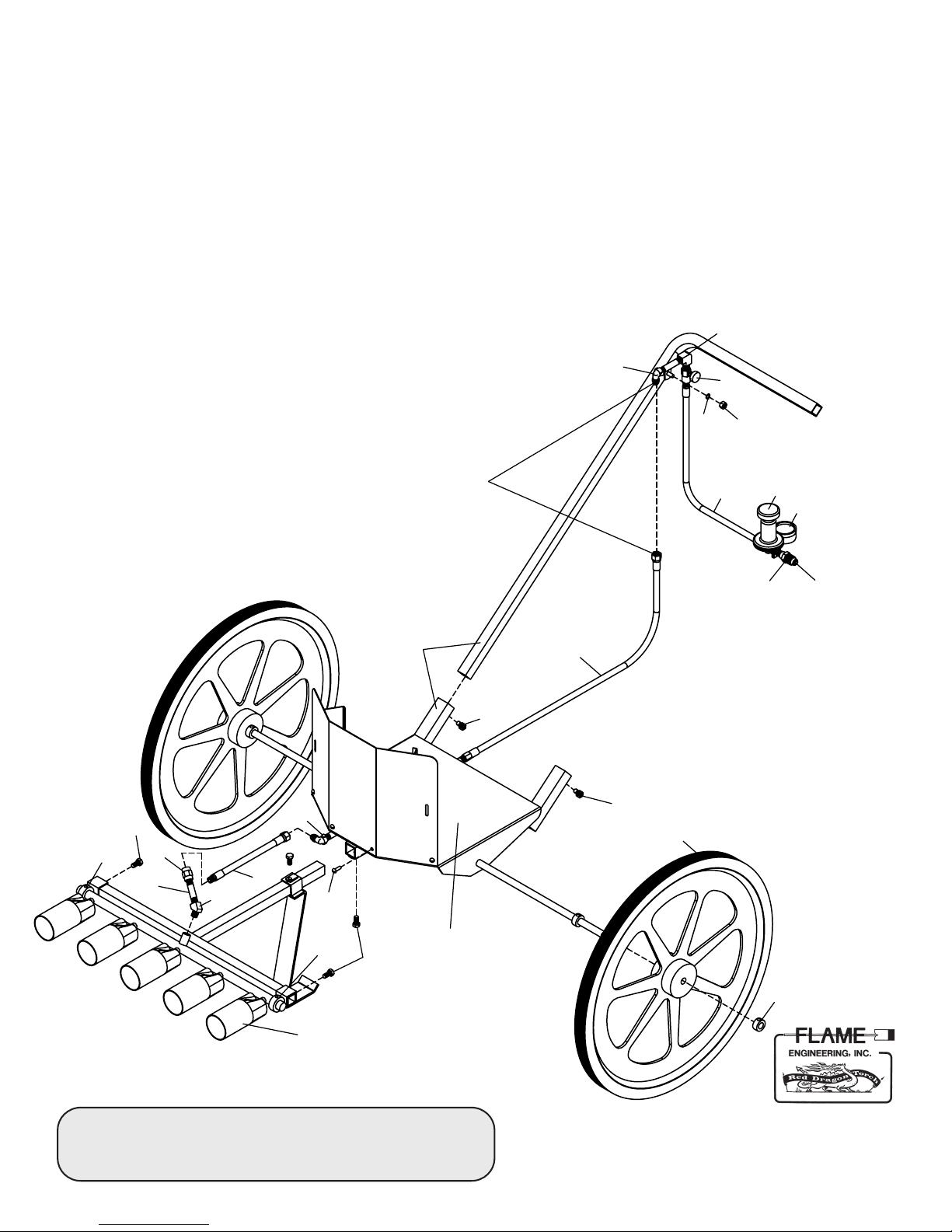

1. The torch manifold angle may be adjusted by loosening

the lock collars (D) holding the manifold bar. The

manifold may also be adjusted in or out from the unit

by loosening the 3/8 x 1/2 bolt and sliding the tee

bracket.

2. The wheel width may also be adjusted by loosening

and moving the lock collars on the axle. The handle

may also be assembled in a number of positions

depending on which bracket you slide it into and which

direction you point the “L” of the handle.

To Shut Down:

1. Close the LP-Gas cylinder valve.

2. Allow the gas to burn out of hose. After the flame is no

longer visible, turn the flame adjusting valve to the

closed or “off” position. TO RESTART follow lighting

instructions.

Disconnecting From Supply Cylinder:

1. Be certain supply cylinder valve is turned off.

2. Disconnect the P.O.L. nut/nipple fitting on the LP hose

to the propane supply.

3. Replace the protective plastic plug into the cylinder

valve outlet.

Safety Check List:

• Gloves should be used at all times. Long sleeves, long

pants & boots are recommended.

• Use only with cylinders equipped with vapor withdrawal

valves.

• Secure cylinders in a level, upright position. Do not invert or

lay cylinders on their sides.

• Do not apply flame to cylinders to check for leaks or to

increase gas pressure.

• Keep torches, open flame and sources of ignition away from

cylinders, regulators and hose.

• Do not operate torches or any equipment if the odor of

LP-Gas is evident. Immediately shut off all valves and, using

soapy water, check all equipment for leaks.

• Cylinder valves must be protected. Do not hoist a cylinder by

the valve.

• Do not leave the unit unattended while in operation.

• This equipment is for outdoor use only with adequate

ventilation.

• Have a type ABC fire extinguisher on the job site, easily

accessible to the person operating the unit.

WARNING:

Use extreme caution at all times. You are using an intense

open flame. This torch produces an extremely hot and

nearly invisible flame. Read and follow the Safety Check

List and Daily Equipment Check List before attempting to

operate this torch.

CAUTION

• Propane is heavier than air which can cause it to

accumulate in low areas. Be certain all areas are well

ventilated.

• Propane has a distinct ODOR. If you smell it,

IMMEDIATELY discontinue work, extinguish all flames,

locate the leak and correct it, ventilate area

before lighting torch.

• Use extreme caution at all times. This device has an

intense open flame. Disregard of safe practices can result

in severe fire damage, personal injury, or possible death.

• Never direct torch flame toward any person or animal.

FLAME ENGINEERING, INC.

PO Box 577 • 230 West Hwy 4 • LaCrosse, KS 67548

800-255-2469 • 785-222-2873 • Fax 785-222-3619

www.FlameEngineering.com GF-2011-INSTUCT8-2013