FLAME ENGINEERING, INC. • P.O. Box 577 • West Highway 4 • LaCrosse, KS 67548

800-255-2469 • 785-222-2873 • Fax 785-222-3619 • www.FlameEngineering.com 5

RED DRAGON PROPANE FLARE OPERATING INSTRUCTIONS

BEFORE OPERATING THE RED DRAGON PROPANE FLARE:

Make sure you have selected a safe area for placement and operation with

approximately 40 foot radius and a minimum 50 feet of vertical clearance.

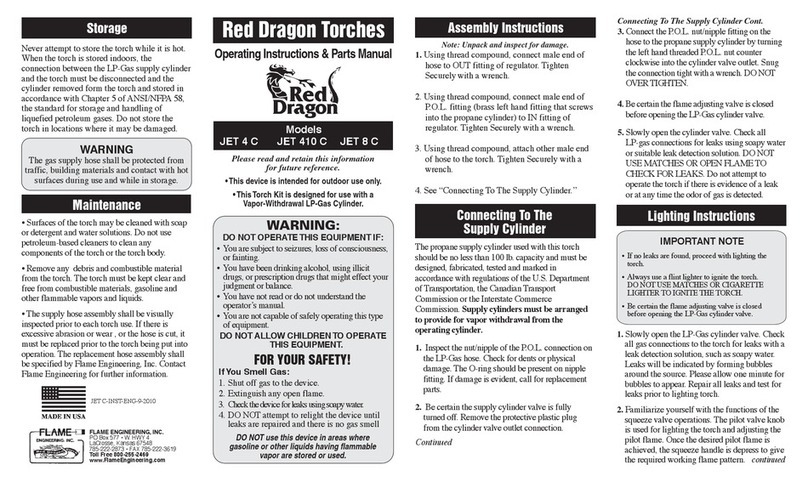

1. Attach pilot hose to an LPG fuel supply with at least

five gallon capacity.

2. Attach the main evacuation line to the tank being

evacuated. This connection will be either a P.O.L

fitting or a commercial tank connection, depending on

the model.

3. Slightly open each tank, one at a time, and test for

leaks at all connections to the Solenoid Control Box

using soapy water or commercial leak testing fluid.

Turn off tanks and correct any leaks before continuing.

Repeat this step if you have to correct leaks until none

are found.

4. Make certain that the main and remote switches are

in the "OFF" position. Slowly open each tank valve

fully. Connect electrical power cord to a 110 volt A.C.

power source.

NOTE: The pilot hose is equipped with a safety P.O.L. fitting.

If the valve on the pilot fuel container is turned on too

quickly, the P.O.L. fitting will check (you may hear a click)

just as it would if the hose ruptured. This check valve

restricts flow and will result in failure of the pilot to light or

result in an insufficient pilot flame. REMEMBER, ALWAYS

TURN THE TANK ON SLOWLY!

5. After making certain the remote switch is in the

"OFF" position, move the main switch to the "ON"

position. The RED indicator light will come on. The

pilot torch should now automatically light.

NOTE: It is possible you will hear the buzzing sound of

the electrical spark attempting to light the pilot burner.

The ignition system will cycle in seven seconds. The

ignition system will attempt to re-light after a 7 second

delay. A third ignition will be attempted. Failure to

establish a pilot results in the unit locking out.

Should the pilot not achieve ignition, turn the main

switch "OFF", wait 30 seconds and start again. It

may be necessary to repeat this procedure several

times to purge sufficient fuel through the pilot fuel

lines.

Once the pilot is burning, the system will continue

to monitor itself. If the pilot torch goes out, an

automatic relight is attempted. If reignition does

not occur within 10 seconds, the system will

automatically shut down and the operator should

start again at step 4 in these instructions.

6. After pilot is ignited, move the remote switch to

the "ON" position to start evacuation of the main

tank.Leak test hose connections from torch and

flare tube to the solenoid control box using soapy

water or commercial leak detector.

LIGHTING PROCEDURES

SHUT DOWN PROCEDURES

1. Turn the valve off on the tank being evacuated and allow all LP-Gas to escape from the fuel line.

2. Turn the remote switch to "OFF".

3. Close the pilot tank valve.

4. After pilot has burned out, turn main switch to "OFF".

5. Disconnect the unit from the power supply and disconnect hoses from both tanks.

Before Starting, Make sure the "Main" switch and the "Remote" switch are in the "OFF" position.