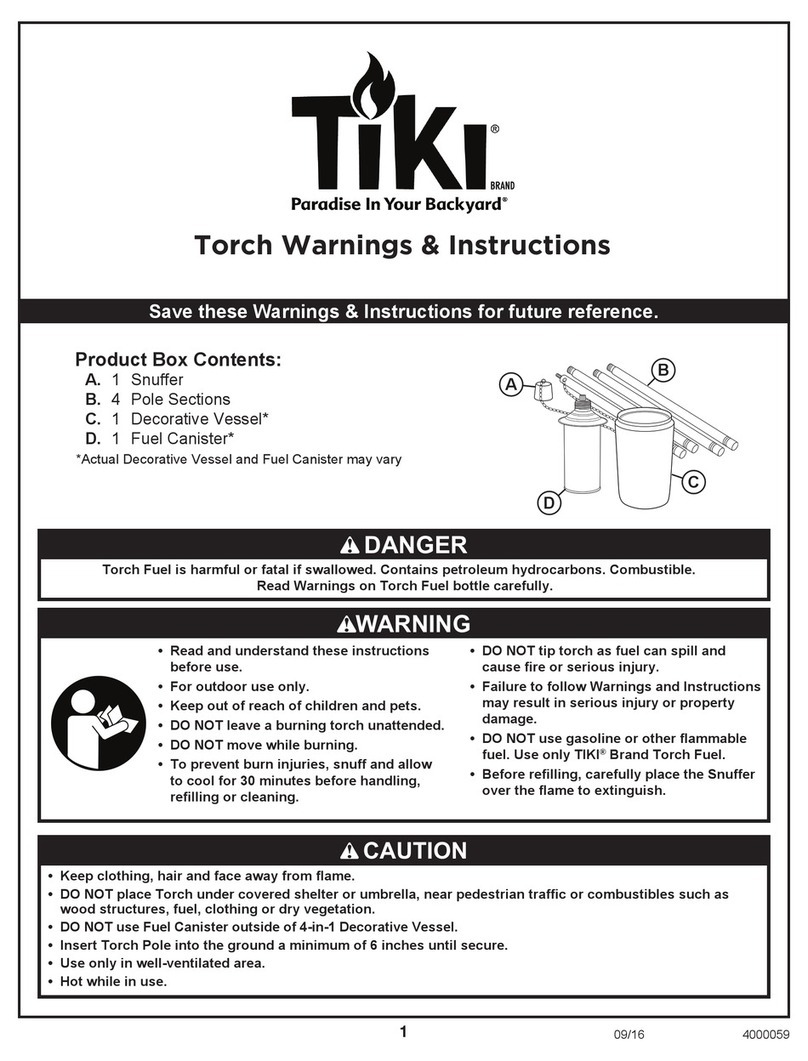

Models

JET 4 C JET 410 C JET 8 C

Red Dragon Torches

Operating Instructions & Parts Manual

Please read and retain this information

for future reference.

•This device is intended for outdoor use only.

• This Torch Kit is designed for use with a

Vapor-Withdrawal LP-Gas Cylinder.

FOR YOUR SAFETY!

If You Smell Gas:

1. Shut off gas to the device.

2. Extinguish any open flame.

3. Check the device for leaks using soapy water.

4. DO NOT attempt to relight the device until

leaks are repaired and there is no gas smell

DO NOT use this device in areas where

gasoline or other liquids having flammable

vapor are stored or used.

Note: Unpack and inspect for damage.

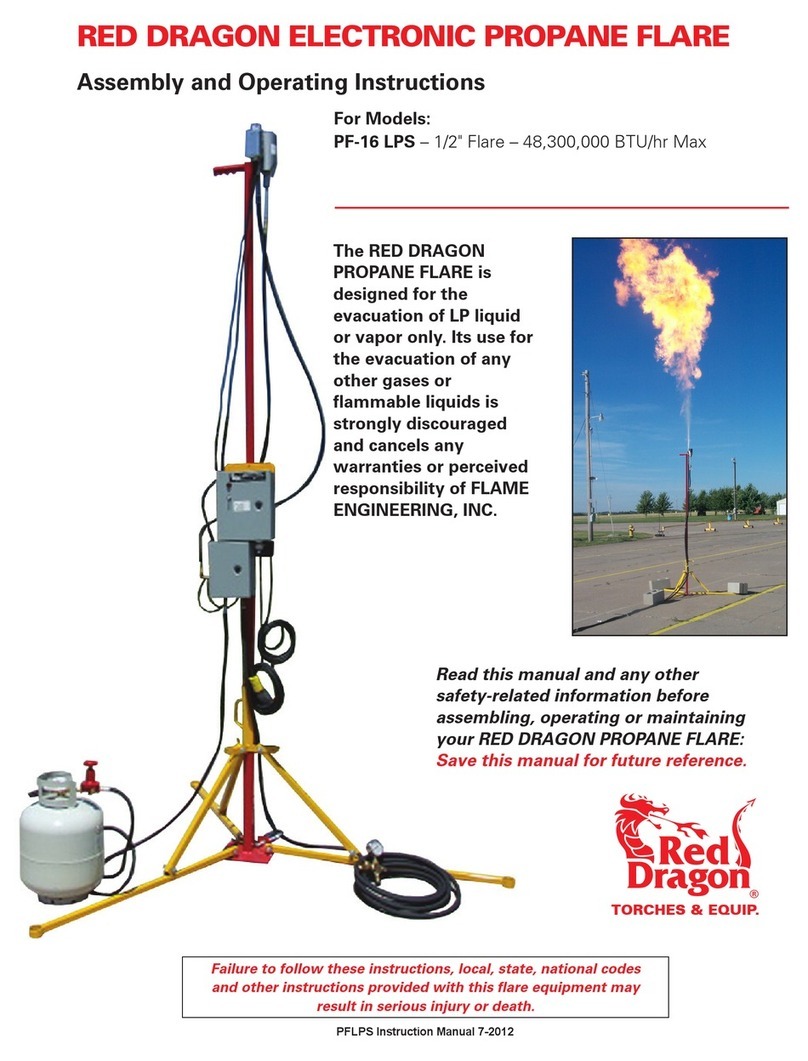

1. Using thread compound, connect male end of

hose to OUT fitting of regulator. Tighten

Securely with a wrench.

2. Using thread compound, connect male end of

P.O.L. fitting (brass left hand fitting that screws

into the propane cylinder) to IN fitting of

regulator. Tighten Securely with a wrench.

3. Using thread compound, attach other male end

of hose to the torch. Tighten Securely with a

wrench.

4. See “Connecting To The Supply Cylinder.”

Assembly Instructions

Connecting To The

Supply Cylinder

The propane supply cylinder used with this torch

should be no less than 100 lb. capacity and must be

designed, fabricated, tested and marked in

accordance with regulations of the U.S. Department

of Transportation, the Canadian Transport

Commission or the Interstate Commerce

Commission. Supply cylinders must be arranged

to provide for vapor withdrawal from the

operating cylinder.

1. Inspect the nut/nipple of the P.O.L. connection on

the LP-Gas hose. Check for dents or physical

damage. The O-ring should be present on nipple

fitting. If damage is evident, call for replacement

parts.

2. Be certain the supply cylinder valve is fully

turned off. Remove the protective plastic plug

from the cylinder valve outlet connection.

Continued

Never attempt to store the torch while it is hot.

When the torch is stored indoors, the

connection between the LP-Gas supply cylinder

and the torch must be disconnected and the

cylinder removed form the torch and stored in

accordance with Chapter 5 of ANSI/NFPA 58,

the standard for storage and handling of

liquefied petroleum gases. Do not store the

torch in locations where it may be damaged.

WARNING

The gas supply hose shall be protected from

traffic, building materials and contact with hot

surfaces during use and while in storage.

• Surfaces of the torch may be cleaned with soap

or detergent and water solutions. Do not use

petroleum-based cleaners to clean any

components of the torch or the torch body.

• Remove any debris and combustible material

from the torch. The torch must be kept clear and

free from combustible materials, gasoline and

other flammable vapors and liquids.

•The supply hose assembly shall be visually

inspected prior to each torch use. If there is

excessive abrasion or wear , or the hose is cut, it

must be replaced prior to the torch being put into

operation. The replacement hose assembly shall

be specified by Flame Engineering, Inc. Contact

Flame Engineering for further information.

Storage

Maintenance

JET C-INST-ENG-9-2010

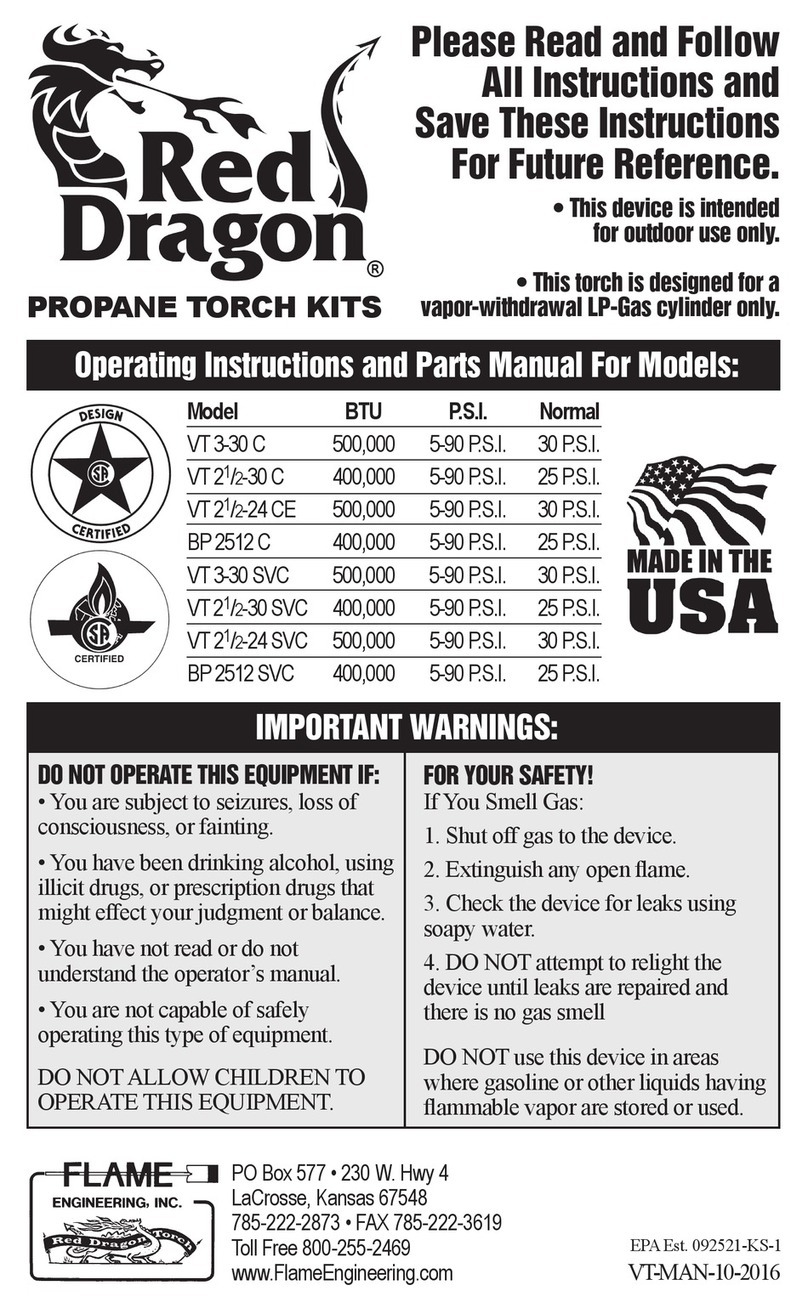

WARNING:

DO NOT OPERATETHIS EQUIPMENT IF:

• You are subject to seizures, loss of consciousness,

or fainting.

• You have been drinking alcohol, using illicit

drugs, or prescription drugs that might effect your

judgment or balance.

• You have not read or do not understand the

operator’s manual.

• You are not capable of safely operating this type

of equipment.

DO NOT ALLOW CHILDRENTO OPERATE

THIS EQUIPMENT.

FLAME ENGINEERING, INC.

PO Box 577 • W. HWY 4

LaCrosse, Kansas 67548

785-222-2873 • FAX 785-222-3619

Toll Free 800-255-2469

www.FlameEngineering.com

1. Slowly open the LP-Gas cylinder valve. Check

all gas connections to the torch for leaks with a

leak detection solution, such as soapy water.

Leaks will be indicated by forming bubbles

around the source. Please allow one minute for

bubbles to appear. Repair all leaks and test for

leaks prior to lighting torch.

2. Familiarize yourself with the functions of the

squeeze valve operations. The pilot valve knob

is used for lighting the torch and adjusting the

pilot flame. Once the desired pilot flame is

achieved, the squeeze handle is depress to give

the required working flame pattern. continued

Lighting Instructions

IMPORTANT NOTE

• If no leaks are found, proceed with lighting the

torch.

• Always use a flint lighter to ignite the torch.

DO NOT USE MATCHES OR CIGARETTE

LIGHTER TO IGNITE THE TORCH.

• Be certain the flame adjusting valve is closed

before opening the LP-Gas cylinder valve.

Connecting To The Supply Cylinder Cont.

3. Connect the P.O.L. nut/nipple fitting on the

hose to the propane supply cylinder by turning

the left hand threaded P.O.L. nut counter

clockwise into the cylinder valve outlet. Snug

the connection tight with a wrench. DO NOT

OVER TIGHTEN.

4. Be certain the flame adjusting valve is closed

before opening the LP-Gas cylinder valve.

5. Slowly open the cylinder valve. Check all

LP-gas connections for leaks using soapy water

or suitable leak detection solution. DO NOT

USE MATCHES OR OPEN FLAME TO

CHECK FOR LEAKS. Do not attempt to

operate the torch if there is evidence of a leak

or at any time the odor of gas is detected.