-2-

Bulletin No. CTL-D Released 2018-06-30

Drawing No. LP0652

INSTALLATION

Run wire to be monitored through opening in the sensor. The CTL

Series transducers work in the same environment as motors, contactors,

heaters, pull-boxes, and other electrical enclosures. They can be

mounted in any position or hung directly on wires with a wire tie. Just

leave at least one inch (25.4 mm) distance between sensor and other

magnetic devices.

Split‐CoreVersions

Press the tab in the direction as shown to open the sensor. After

placing the wire in the opening, press the hinged portion firmly downward

until a definite click is heard and the tab pops out fully.

KEEPSPLIT‐CORESENSORSCLEAN.

Silicone grease is factory applied on the mating surfaces to prevent rust

and improve performance. Be careful not to allow grit or dirt onto the

grease in the contact area. Operation can be impaired if the mating

surfaces do not have good contact. Check visually before closing.

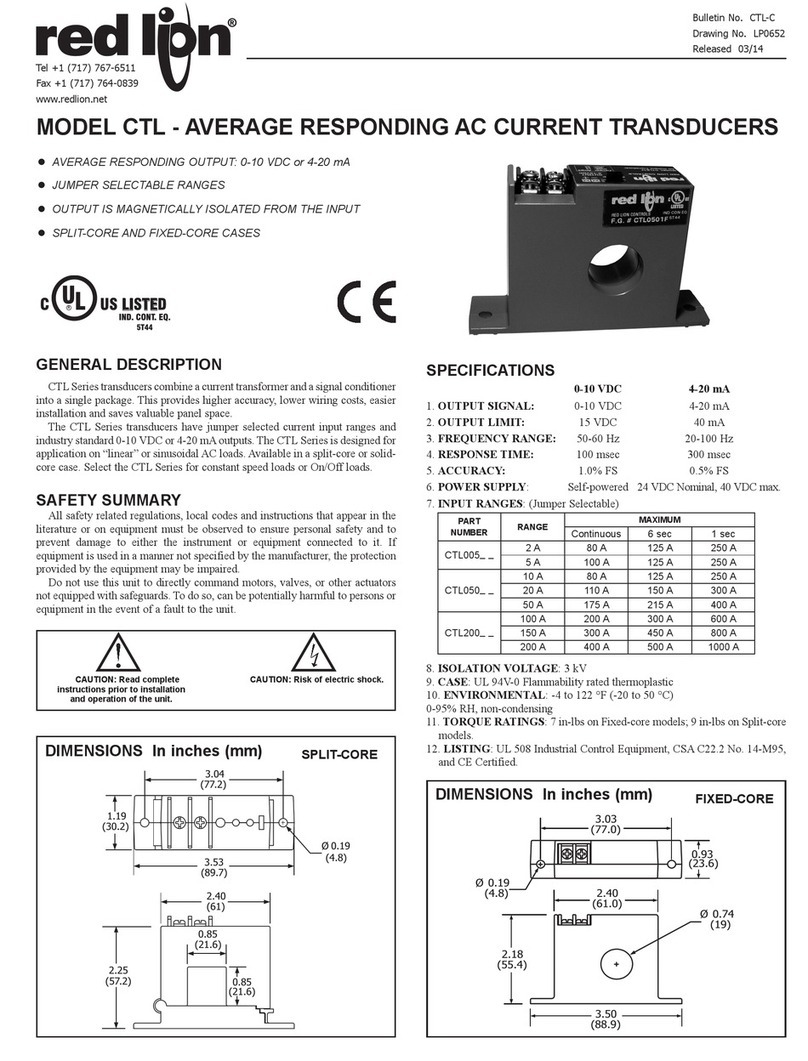

OUTPUTWIRING

Connect control or monitoring wires to the sensor. Use up to 14 AWG

copper wire and tighten terminals to 7 inch-pounds torque for solid-core

models and 9 inch-pounds torque for split-core models. Be sure the

output load or loop power requirements are met (see diagram).

POWERSUPPLY

CONNECTIONS

RANGESELECT

CTL series transducers feature field selectable ranges. The ranges are

factory calibrated, eliminating time consuming and inaccurate field setting

of zero or span.

1. Determine the normal operating amperage of your monitored circuit

2. Select the range that is equal to or slightly higher than the normal

operating amperage.

3. Place the range jumper in the appropriate position.

TROUBLESHOOTING

0‐10VDCOUTPUTMODELS

1. Sensor Has No Output

A. Polarity is not properly matched. Check and correct wiring polarity.

B. Monitored load is not AC or is not on. Check that the monitored load

is AC and that it is actually on.

C. Split Core models: The core contact area may be dirty. Open the

sensor and clean the contact area.

2. Output Signal Too Low

A. The jumper may be set in a range that is too high for current being

monitored. Move jumper to the correct range.

B. Output load too low. Check output load, be sure that it is at least

100Kand preferably 1 M.

C. Monitored current is below minimum required. Loop the monitored

wire several times through the aperture until the “sensed” current

rises above minimum. Sensed Amps = (Actual Amps) x (Number of

Loops). Count loops on the inside of the aperture.

3. Output Signal Is Always At Maximum

A. Monitored load is not AC or is not on. Check that the monitored load

is AC and that it is actually on.

4‐20mAOUTPUTMODELS

1. Sensor Has No Output

A. Power supply is not properly sized. Check power supply voltage and

current rating.

B. Polarity is not properly matched. Check and correct wiring polarity

C. Split Core models: The core contact area may be dirty. Open the

sensor and clean the contact area.

2. Output Signal Too Low

A. The jumper may be set in a range that is too high for current being

monitored. Move jumper to the correct range.

B. The load current is not sinusoidal.

C. Monitored current is below minimum required. Loop the monitored

wire several times through the aperture until the “sensed” current

rises above minimum. Sensed Amps = (Actual Amps) x (Number of

Loops). Count loops on the inside of the aperture.

3. Sensor Is Always At 4 mA

A. Monitored load is not AC or is not on. Check that the monitored load

is AC and that it is actually on.

4. Output Signal Is Always At 20 mA

A. The jumper may be set in a range that is too low for current being

monitored. Move jumper to the correct range.

ORDERINGINFORMATION

Important!

Keep Contact

Area CLEAN!

To Open

Press Tab

Toward Hinge.

250 1000750

Total Loop Impedance (Ohms)

25

20

15

10

5

Operating Range

V

L

= 12VDC + (R

L

×0.020A)

where V

L

= Minimum Loop Supply

R

L

= Total Loop Resistance (Ohms)

500

0

2(+)1(–)

Output

Range Jumper

(+)(–)

24 VDC Power

(+)

(–)

Load

(Controller,

Meter, etc.)

2(+)1(–)

Output

Range Jumper

4–20mA Option

10 VDC Option 1M

:

Recommended

100K

:

Acceptable (Add

Notes: Captive screw terminals.

12–22 AWG solid or stranded.

Observe polarity.

1.3% error for 100 K)

TYPE MODEL NO. DESCRIPTION PART

NUMBER

SPLIT CORE

CTL12S 2-5 A / 4-20 mA CTL0052S

CTL52S 10-50 A / 4-20 mA CTL0502S

CTL22S 100-200 A / 4-20 mA CTL2002S

FIXED CORE

4-20 mA

CTL52F 10-50 A / 4-20 mA CTL0502F

CTL22F 100-200 A / 4-20 mA CTL2002F

FIXED CORE

0-10 VDC

CTL51F 10-50 A / 10 VDC CTL0501F

CTL21F 100-200 A / 10 VDC CTL2001F