TILLQUIST LQT400 User manual

i

Thank you for choosing LQT400 from Hugo Tillquist AB!

The LQT400 is a 3-phase multi-transducer with 2 analog outputs that can

be configured to measure any electrical quantity. All areas for AC current

and voltage (True RMS) are covered by one single unit.

Our free transducer configuration software “ConfigLQT” can be used to

easily configure the LQT400 via its USB-port.

ii

Table of contents

Thank you for choosing LQT400 from Hugo Tillquist AB!.........................................i

1Product description...........................................................................................1

1.1 Technical data ...........................................................................................1

2Instructions........................................................................................................2

2.1 Mounting...................................................................................................2

2.2 Installation.................................................................................................2

2.3 Operation ..................................................................................................2

2.4 Warning!....................................................................................................2

2.5 Maintenance .............................................................................................2

2.6 Inputs - Outputs ........................................................................................3

2.7 Symbols on the appliance .........................................................................3

2.8 Installation of ConfigLQT...........................................................................3

3Configuration.....................................................................................................4

3.1 Connection to computer...........................................................................4

3.1.1 Monitored parameters ......................................................................5

3.2 Input settings.............................................................................................5

3.2.1 System connection.............................................................................6

3.3 Analog Outputs .........................................................................................8

3.3.1 Measured quantities..........................................................................9

3.3.2 Example of settings for the analog outputs.....................................10

3.4 Save / Open saved configuration............................................................11

3.4.1 Save a configuration to a file ...........................................................11

3.4.2 Open a configuration from a saved file ...........................................11

4Firmware upgrade...........................................................................................12

1

1Product description

The LQT400 is a configurable 3-phase multi-transducer, capable for measuring any

electrical quantity of a network. It is possible to choose up to 2 of any electrical

quantities and link them to the analog outputs. The configuration is done using our

freeware ConfigLQT via the mini USB-port.

1.1 Technical data

Inputs

Voltage

Input (Un)

100 –400 V main voltage (nominal)

Measuring range

0 –500 V TRMS

Overload

1.5 x Un –continuously, 2 x Un –10 s

Consumption

Un x 1 mA / phase

Frequency

10…40…70…120 Hz

10…15…18…120 Hz (option for 16⅔ Hz)

Current

Input (In)

1 –5 A

Measuring range

0 –10 A TRMS

Overload

2 x In continuously, 10 x In 15 s, 40 x In 1 s

Consumption

< 0.05 VA / phase

AUX Supply

Universal current

24 (2W) –253VDC (3W) (±5%)

80 (4VA) –253VAC (5VA), 50/60 Hz (±5%)

Outputs

Analog

Quantity

2 pcs

Range

+/- 20 mA

Load

max 750 ohm (15V)

Response time

< 100 ms

General data

Accuracy class

0.2

Overvoltage category

CAT III

Max rated values

519 V (L-L) / 300 V (L-N), 10 A

Galvanic insulation

All connections are galvanically separated

USB

1 pc for configuration

Temperature range

-10 to +55 °C (operation), -40 to +70 °C (storage)

Temperature coefficient < 0.1% / 10 °C

Humidity

< 80%

Test voltage

4 kV, 50 Hz, 1 min.

Pollution degree

2

IP Class

Housing IP40, terminals IP20

Dimensions (W x H x D)

70 x 132 x 137 mm –DIN-rail

Mounting

Indoors - Up to 2000 meters height

Weight

~0.5 kg

Standards

SS-EN 60688 Transducers

SS-EN 61010-1, 61010-2-030 Safety

EN 61000-6-2, -6-4, -6-5 EMC

2

2Instructions

2.1 Mounting

The transducer is mounted on a 35mm DIN rail on a wall or device cabinet for suitable

protection. The enclosure shall not be accessible without tools.

2.2 Installation

The installation is to be made by competent personnel and in accordance with

applicable regulations. Before installation please check that the transducer has the

correct type and complies with the installation needs. The connection to the transducer

is done through the terminals that are designed for a maximum of 6 mm² cable in

accordance with connection diagram. An external switch shall be used so that the unit

can be deenergized during disassembly. It shall be appropriately positioned, easy to

reach and marked as a switch for the transducer. The measuring circuits from the

current transformers must be short-circuited before disconnection. The unit must be

protected against possible overcurrent by automatic circuit breaker.

2.3 Operation

The transducer is intended for operation at an altitude not exceeding 2000m and in an

environment that is not considered as wet location.

2.4 Warning!

Connection must comply with current regulations for systems with rated voltage up to

1000 V.

Before switching on or off and if the housing is removed, all voltages to the appliance

must be switched off.

2.5 Maintenance

The transducer requires no maintenance. Any repairs shall be performed by trained

personnel or the appliance shall be returned to the supplier for repair.

Function and safety are only guaranteed if the instructions in this manual are followed.

3

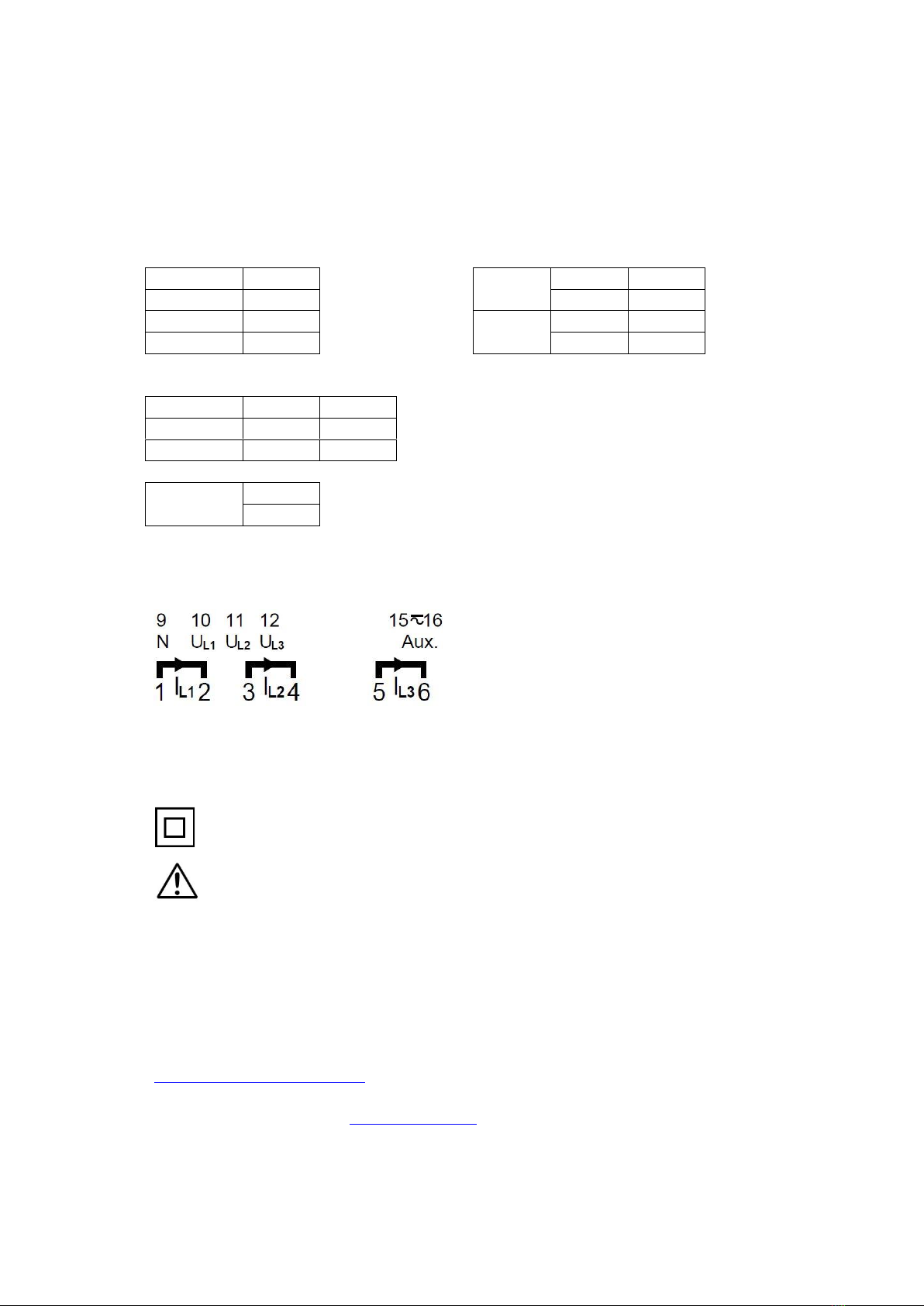

2.6 Inputs - Outputs

Inputs

Analog outputs

Nr

Chanel

Nr

-/+

U1

10

A1

13

-

U2

11

14

+

U3

12

A2

7

-

N

9

8

+

IN

OUT

I1

1

2

I2

3

4

I3

5

6

AUX

SUPPLY

15

16

Terminal diagram

2.7 Symbols on the appliance

Double insulated device.

Warning for life-threatening or hazardous for properties situations.

2.8 Installation of ConfigLQT

The installation kit consists of the configuration software and a driver for the USB

connection to LQT400. ”.NET Framework”version 4.0 is a software from Microsoft,

usually installed by default, that is necessary for the proper operation of ConfigLQT. If

not already installed, it can be downloaded by the following link:

http://www.microsoft.com/net/.

Download ConfigLQT from www.tillquist.com, unzip the files and install it by running

setup.

4

3Configuration

3.1 Connection to computer

Connect a USB-cable between the USB-port on LQT400 and the computer. Use a cable

with contacts type A and mini B. No safety action is required while connecting the USB

cable to the device.

Start ConfigLQT and click Connect.

The connection status will change to Connected with a green background and

information about the transducer will be displayed once the connection is established.

Various basic parameters of the transducer as well as the measured values are displayed

on the screen when the transducer is connected to a measuring object. The measured

values can be shown as Primary or Secondary values.

The measuring range covered by LQT 400 is ‘Wide’which means that the transducer can

be connected to networks with a nominal main voltage between 100 and 400 V AC and a

nominal current between 1 and 5 A. Using the ConfigLQT it is possible to configure the

transducer in order to be used for all different connections in 1-phase and 3-phase

networks shown on page 6.

5

3.1.1 Monitored parameters

P

Power

P=S*cos(φ) [W]

IS

System current with sign

Q

Reactive power

Q=S*sin(φ) [var]

PF

Power factor

PF=P/S

S

Apparent power

S=rot(3)*Uh*Ih [VA]

QF

Reactive power factor

QF=Q/S

U

Voltage

LF

= sign(Q)*(1-|PF|)

I

Current

PA

Phase angle

F

Frequency

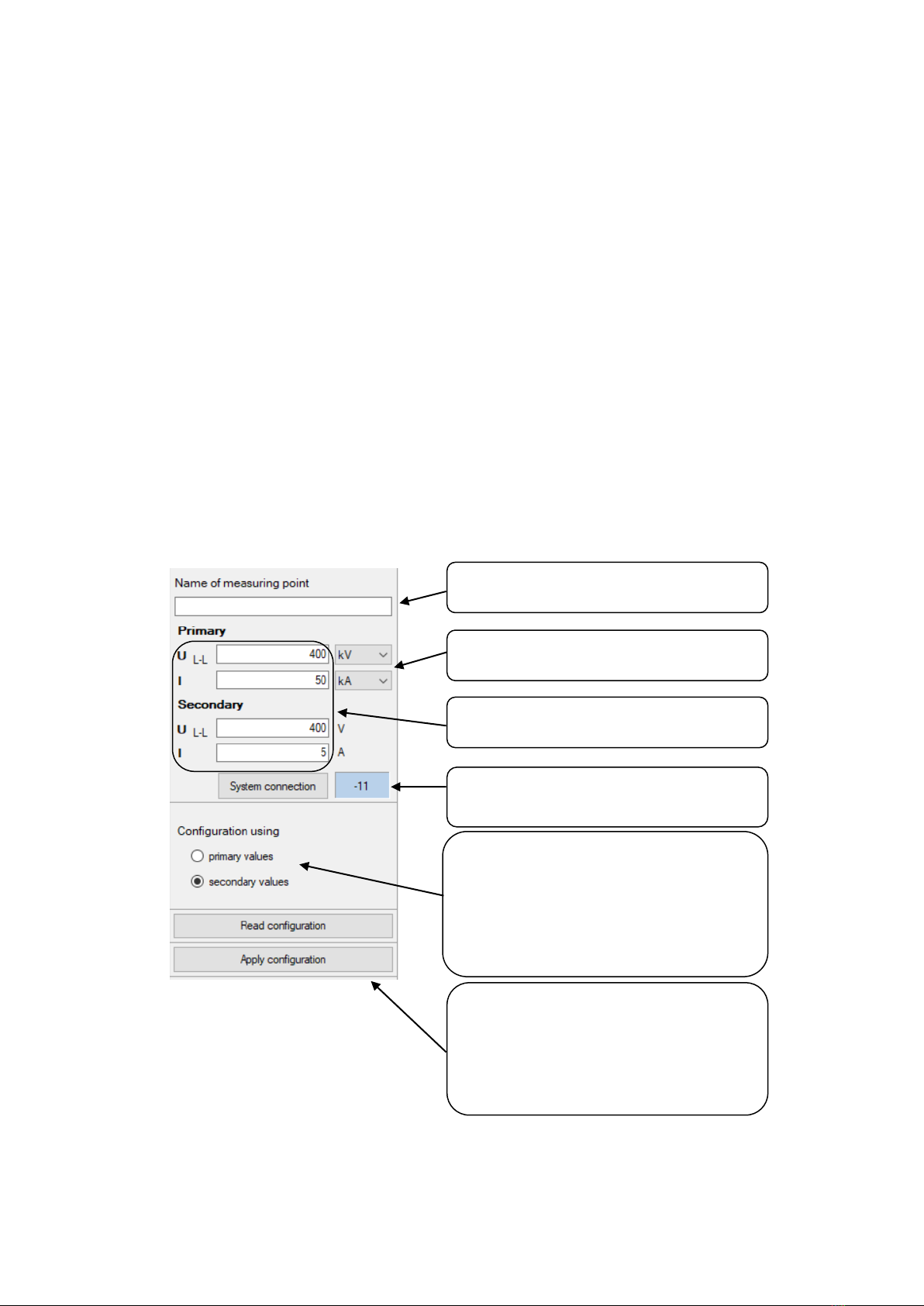

3.2 Input settings

Read configuration: Read present settings

from LQT400 to ConfigLQT.

Apply configuration: Save data to LQT400.

Configuration using: choose which values will

be shown.

•Primary values –values based on

primary data.

•Secondary values –values based on

secondary values.

Primary: U: V, kV, MV

I: A, kA

Name of measuring point

Free text –20 characters

System connection: For more information see

page 6.

Transformer ratio

6

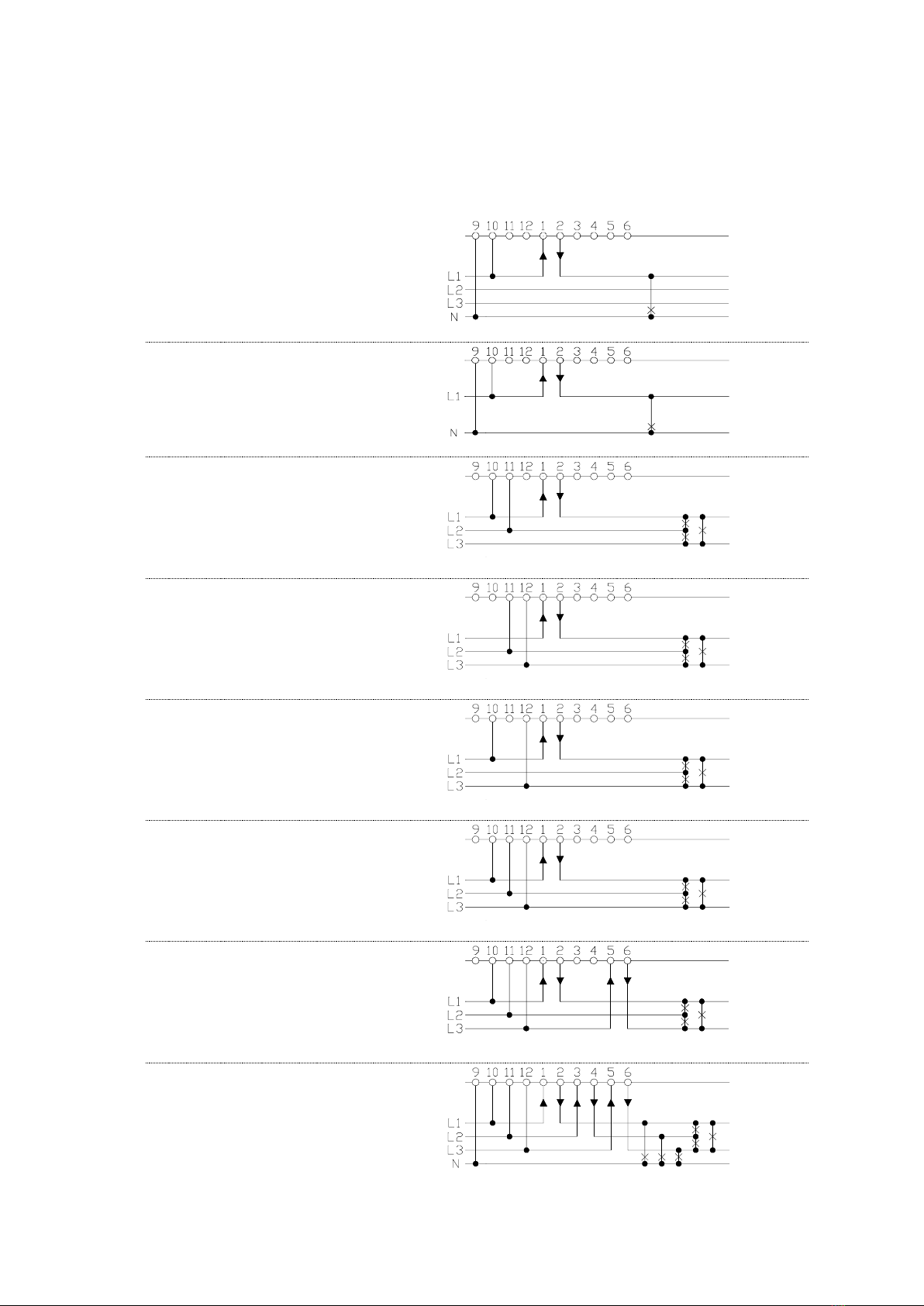

3.2.1 System connection

Select the appropriate diagram for the used network.

-00

3-phase

1 system

3-phase symmetrical load

-01

1-phase

1 system

-02

3-phase

1 system

3-phase symmetrical load

-03

3-phase

1 system

3-phase symmetrical load

-04

3-phase

1 system

3-phase symmetrical load

-05

3-phase

1 system

3-phase symmetrical load

-09

3-phase

2 systems

3-phase asymmetrical load

-11

3-phase

3 systems

3-phase asymmetrical load

7

System

connection

Application

I1

I2

I3

N

U1

U2

U3

U12

U23

U31

U =

I =

P =

Q =

S =

-00

4 wires

3-phase symmetrical load

X

-

-

X

X

-

-

-

-

-

U1

I1

P1*3

Q1*3

S1*3

-01

1 wire

1 phase

X

-

-

X

X

-

-

-

-

-

U1

I1

P1

Q1

S1

-02

3 wires

3-phase symmetrical load

X

-

-

-

-

-

-

X

-

-

-

-

PI1U12

QI1U12

I1*U12*√3

-03

3 wires

3-phase symmetrical load

X

-

-

-

-

-

-

-

X

-

-

-

PI1U23

QI1U23

I1*U23*√3

-04

3 wires

3-phase symmetrical load

X

-

-

-

-

-

-

-

-

X

-

-

PI1U31

QI1U32

I1*U31*√3

-05

3 wires

3-phase symmetrical load

X

-

-

-

X

X

X

X

X

X

-

I1

P1*3

Q1*3

S1*3

-09

3 wires

3-phase asymmetrical

load

X

-

X

-

X

X

X

X

X

X

-

(I1+I3)*3/2

(P1+P3)*3/2

(Q1+Q3)*3/2

(S1+S3)*3/2

-11

4 wires

3-phase asymmetrical

load

X

X

X

X

X

X

X

X

X

X

(U1+U2+U3)/3

(I1+I2+I3)/3

P1+P2+P3

Q1+Q2+Q3

S1+S2+S3

-11

4 wires

3-phase asymmetrical

load

Open Delta

X

X

X

-

X

X

X

X

X

X

(U1+U2+U3)/3

(I1+I2+I3)/3

P1+P2+P3

Q1+Q2+Q3

S1+S2+S3

8

3.3 Analog Outputs

Click Analog Outputs tab to configure the analog outputs.

The analog outputs can be freely configured to the desired measured quantity within

the allowed measuring ranges. Select the quantity you want to measure using the drop-

down list. In the Input Secondary field the start values are to be written in the first

space, any breakpoints afterwards and the end value at last. Under Output Value the

corresponding values of the output signal are indicated.

Click Apply configuration to transfer and save the new settings in the transducer.

To simulate the outputs for testing purposes, please choose Fixed Output, fill in the

desired value and click Apply configuration.

Activation of an analog output.

Drop-down list for selection of

measured values and desired

rows for the results .

9

3.3.1 Measured quantities

Prefix

Quantity

Calculation

System / Phase

I

Input current

(I1+I2+I3)/3

System

I1

Phase current L1

L1

I2

Phase current L2

L2

I3

Phase current L3

L3

U

Input voltage

(U1+U2+U3)/3

System

U1

L1 Phase voltage

L1

U2

L2 Phase voltage

L2

U3

L3 Phase voltage

L3

P

Active power

P1+P2+P3

System

P1

Active power L1

L1

P2

Active power L2

L2

P3

Active power L3

L3

Q

Reactive power

Q1+Q2+Q3

System

Q1

Reactive power L1

L1

Q2

Reactive power L2

L2

Q3

Reactive power L3

L3

S

Apparent power

S1+S2+S3

System

S1

Apparent power L1

L1

S2

Apparent power L2

L2

S3

Apparent power L3

L3

U12

Main voltageL1-L2

L1 - L2

U23

Main voltage L2-L3

L2 - L3

U31

Main voltage L3-L1

L3 - L1

PF

Active power factor

P/S

System

PF1

Active power factor

COS(φ1)=P1/S1

L1

PF2

Active power factor

COS(φ2)=P2/S2

L2

PF3

Active power factor

COS(φ3)=P3/S3

L3

QF

Reactive power factor

Q/S

System

QF1

Reactive power factor

SIN(φ1)=Q1/S1

L1

QF2

Reactive power factor

SIN(φ2)=Q2/S2

L2

QF3

Reactive power factor

SIN(φ3)=Q3/S3

L3

LF

LF factor

sign(Q)*(1-|PF|)

System

LF1

LF factor

sign(Q1)*(1-|PF1|)

L1

LF2

LF factor

sign(Q2)*(1-|PF2|)

L2

LF3

LF factor

sign(Q3)*(1-|PF3|)

L3

PA

Phase angel

PA=(PA1+PA2+PA3)/3

System

PA1

Phase angel

φ1=ARCCOS(P1/S1)/PI*180*sign(P1)

L1

PA2

Phase angel

φ2=ARCCOS(P2/S2)/PI*180*sign(P2)

L2

PA3

Phase angel

φ3=ARCCOS(P3/S3)/PI*180*sign(P3)

L3

IS

Input current with sign

(IS1+IS2+IS3)/3

System

IS1

Phase current with sign

I1*sign(P1)

L1

IS2

Phase current with sign

I2*sign(P2)

L2

IS3

Phase current with sign

I3*sign(P3)

L3

P_I1_U12

Active power, System connection-02

System

P_I1_U23

Active power, System connection -03

System

P_I1_U31

Active power, System connection -04

System

Q_I1_U12

Reactive power, System connection -02

System

Q_I1_U23

Active power, System connection -03

System

Q_I1_U31

Active power, System connection -04

System

F

Frequency

System

Fixed Output

Fixed output

10

3.3.2 Example of settings for the analog outputs

U12

Measuring main voltage

L1-L2

IN: 0 –137,5 V

OUT: 4 –20 mA

Secondary

Analog out

0

4

137,5

20

I1

Measuring current I1

IN: 0 –5 A

OUT: 0 –20 mA

Secondary

Analog out

0

0

5

20

P

Measuring total power

IN: ±50 MW

OUT: ±20 mA

Primary

Analog out

-50000

-20

50000

20

Q

Measuring total power

IN: ±28 MVar

OUT: ±20 mA

Primary

Analog out

-28000

-20

28000

20

U12

Measuring main voltage

L1-L2 with voltlup.

IN: 0-90-137,5 V

OUT: 4-8-20 mA

Secondary

Analog out

0

4

90

8

137,5

20

F

Measuring frequency

45 –55 Hz

IN: 45 –55 Hz

OUT: 4 –20 mA

Secondary

Analog out

45

4

55

20

11

3.4 Save / Open saved configuration

The saved parameters of LQT400 can be saved to a file which can easily be downloaded

to other transducers.

3.4.1 Save a configuration to a file

1. Select File menu and click Save as. .

2. Write a file name and choose a desired folder.

3. Click Save.

3.4.2 Open a configuration from a saved file

1. Select File menu and click Open file.

2. Choose the desired configuration file (XML-document).

3. Click Open.

12

4Firmware upgrade

The LQT400 firmware can be upgraded with the software ConfigLQT. To do so, connect

the transducer to the computer with a USB cable.

1. Start ConfigLQT.

2. Select Firmware Upgrade from Transducer menu.

3. Choose the file with the new firmware and Upgrade.

4. When the upgrade is done, the auxiliary voltage must be disconnected so that

the transducer restarts, allowing the new firmware to take effect.

5. Check that the right firmware version is displayed among the transducer’s data.

Table of contents

Other TILLQUIST Transducer manuals

Popular Transducer manuals by other brands

MKS

MKS 107B manual

Siemens

Siemens 7XV5653-0BA00 operating instructions

GEM

GEM 3140 X Series operating instructions

Meggitt

Meggitt Whittaker C327598 Installation and operation manual

Siedle

Siedle Novotechnik TP1 CANopen user manual

Alcatel Vacuum Technology

Alcatel Vacuum Technology BARATRON 622A instruction manual