Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

Installation Guide

Pressure Monitoring

Z208537-0A Page 5 of 8 ©2023 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0523

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Z208537-0A Page 6 of 8 ©2023 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0523

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Z208537-0A Page 8 of 8 ©2023 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0523

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Z208537-0A Page 7 of 8 ©2023 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0523

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Installation, Wiring

& Conguration

(cont.)

Installation, Wiring

& Conguration

(cont.)

Installation, Wiring

& Conguration

(cont.)

Installation, Wiring

& Conguration

(cont.)

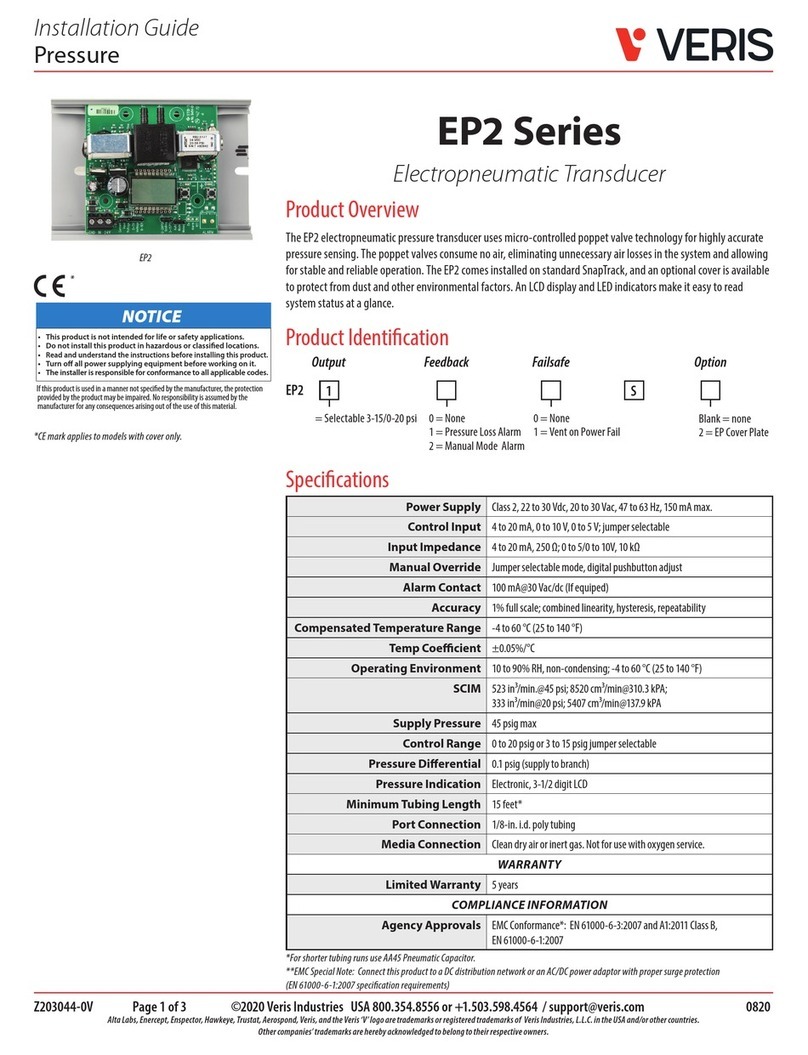

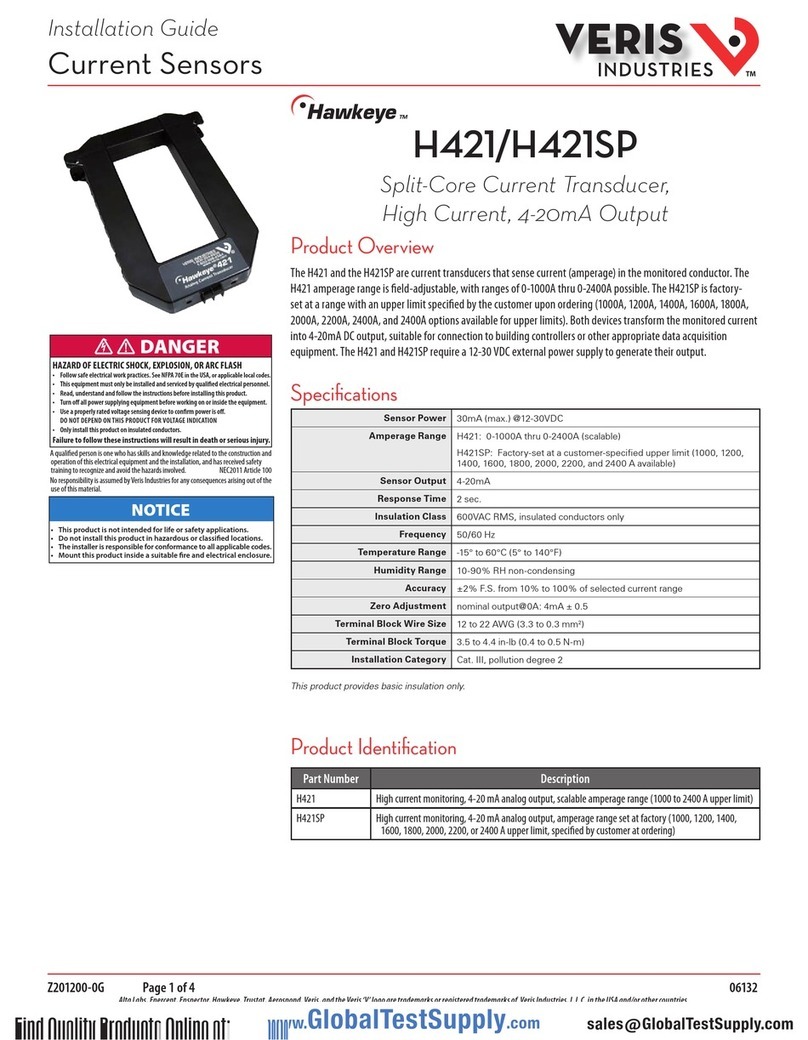

DIP Switch 1: Scale

ON = Pascal (m/s)

OFF = in. WC (ft/min)

DIP Switch 2: Mode

ON = Velocity

OFF = Pressure

DIP Switch 3: Direction**

ON = Unidirectional

OFF = Bidirectional

DIP Switch 4: Response

ON = Slow

OFF = Fast

*DIP switches are all set to OFF by the factory.

**Velocity mode is unidirectional regardless of DIP switch setting.

DIP Switch 5: Output

ON = 4-20 mA

OFF = Voltage

DIP Switch 6: Volt Scale

ON = 0-5 Vdc

OFF = 0-10 Vdc

DIP Switch 7: Unused

DIP Switch 8: Unused

DIP Switch Settings

Scale Mode Direction Response Output Volt Scale

ON Pascal/MPS VelocityUni Slow mA 5V

in. WC/FPM PressureBiFast Volt 10V

Unused

Unused

Unused

Unused

7. Set rotary switch to the desired setting. Align the arrow (not the slot) on the

rotary switch to the desired full-scale range. LCD models momentarily indicate

the selected range.

6. Set DIP switches to desired settings.*

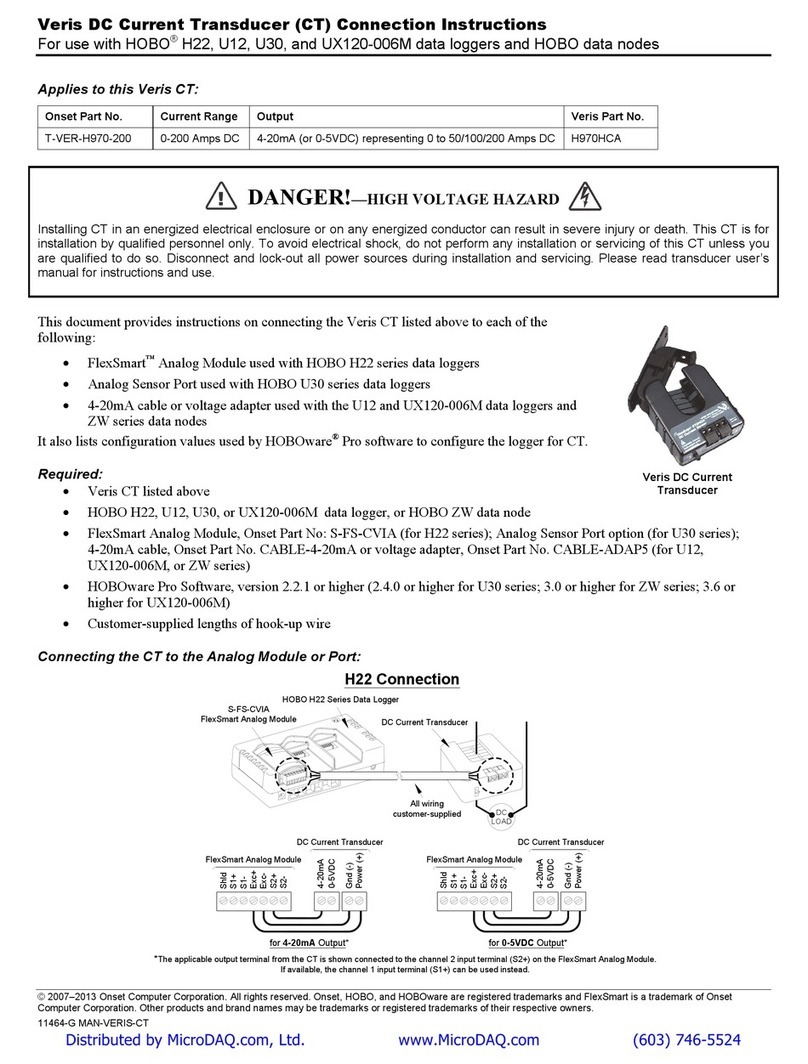

2-wire, 4-20 mA Current Loop Output

DIGITAL CONTROL

Digital

Output

Return

V+

1.000

0

1

2

3

4

5

6

7

PWR

mA RTN{

RMT.

ZERO

ZERO

Operation

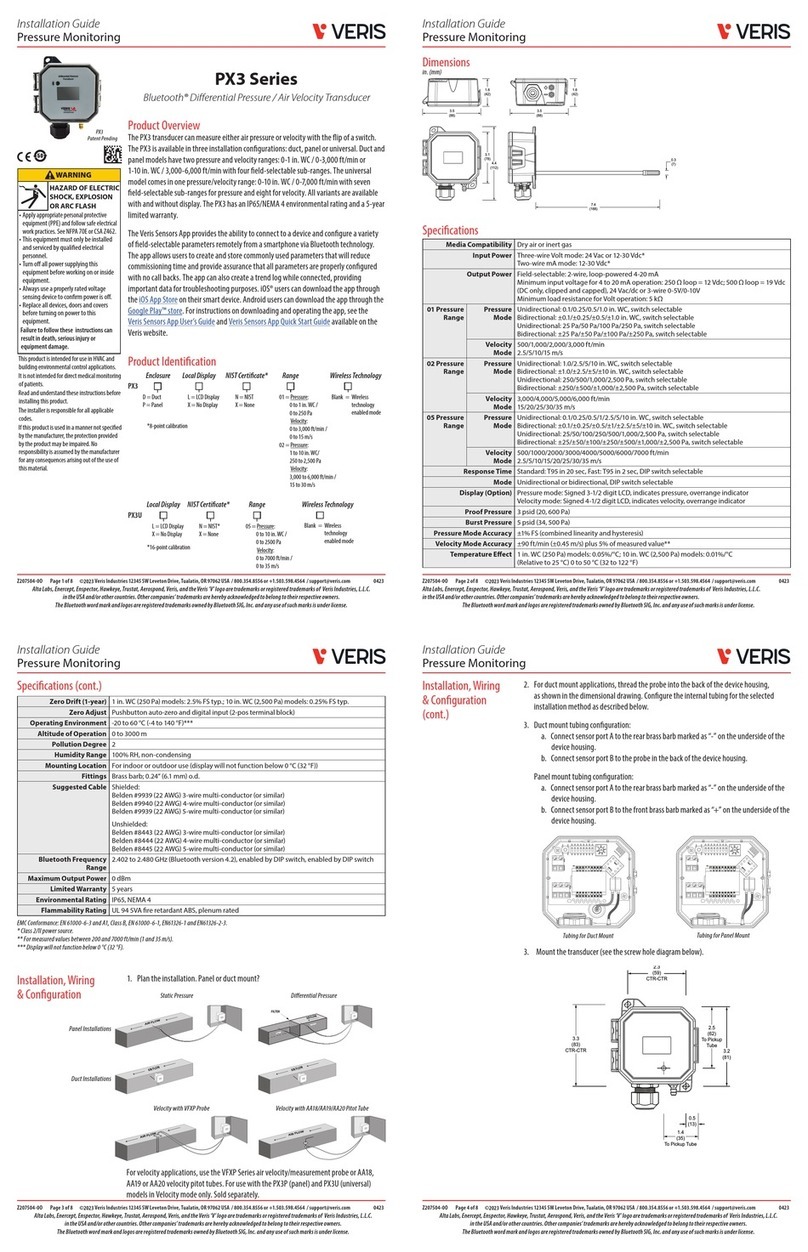

9. Wait ve seconds, then press and hold the ZERO pushbutton for two

seconds or provide contact closure on the AUX ZERO terminal. This will reset

the output and display to zero pressure. For best accuracy, press the ZERO

button while both ports are open to atmospheric pressure. To protect the unit

from accidental zero, this feature is enabled only when the detected pressure

is within about 0.5 in. WC (125 Pa) of factory calibration.

10. Connect desired external tubing to the PX3.

PX3 Series devices employ high performance sensors and sophisticated temperature

compensation circuitry. The sensor achieves its best accuracy after an initial warm-up

period. During the rst few minutes of operation, readings at zero pressure and the

lowest pressure ranges may appear erroneous. Following this initial warm-up period, the

PX3 device maintains its specied accuracy and stability.

The LCD momentarily indicates range ‘SET’ when a selection is made. Pressure is normally

indicated on the display. Units are in inches water column (in. WC), Pascals (Pa) or

kilopascals (kPa) as indicated on the display. The display shows ‘OVR’ when the pressure

is over range.

8. Connect the transmitter to the control system and power supply as indicated

below. Optional: Connect the ZERO terminals to the digital output (contact

closure) of the control system.

Environment-Friendly Use Period (EFUP) Table

China RoHS Compliance

Information

本表格依据SJ/T11364的规定编制。

O: 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572规定的限量要求。

(企业可在此处,根据实际情况对上表中打 的技术原因进行进一步说明。)

This table is made according to SJ/T 11364.

O: indicates that the concentraon of hazardous substance in all of the homogeneous materials

for this part is below the limit as spulated in GB/T 26572.

X: indicates that concentraon of hazardous substance in at least one of the homogeneous

X O O O O O

materials used for this part is above the limit as spulated in GB/T 26572

Z000057-0B

部件名称

Part Name

有害物质-Hazardous Substances

铅(Pb) 汞(Hg) 镉(Cd) 六价铬(Cr (VI)) 多溴联苯 (PBB) 多溴二苯醚(PBDE)

电子件

Electronic

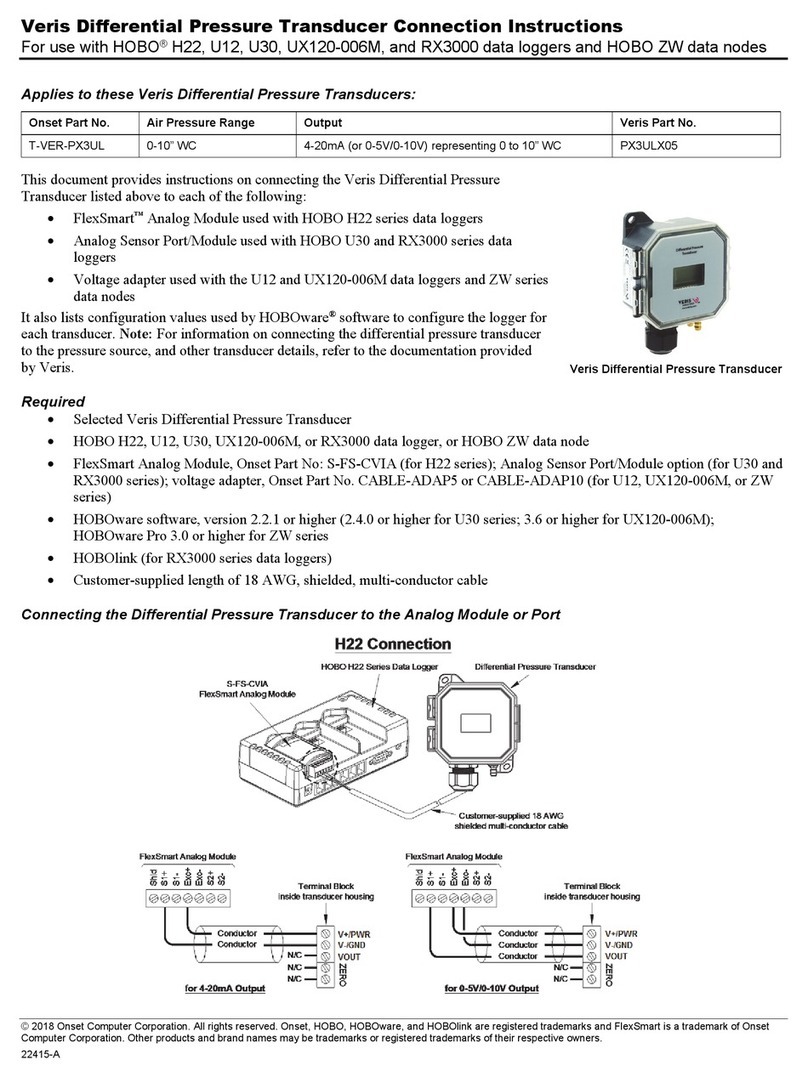

Rotary Switch Settings

Range 1 Model, Field Selectable (WC / ft/min or Pa / m/s)

(P) Pressure Mode (V) Velocity Mode

0 0 to 0.1 in. WC 0 0 to 500 ft/min

1 0 to 0.25 in. WC 1 0 to 1,000 ft/min

2 0 to 0.5 in. WC 2 0 to 2,000 ft/min

3 0 to 1 in. WC 3 0 to 3,000 ft/min

4 0 to 0.1 in. WC 4 0 to 500 ft/min

5 0 to 0.25 in. WC 5 0 to 1,000 ft/min

6 0 to 0.5 in. WC 6 0 to 2,000 ft/min

7 0 to 1 in. WC 7 0 to 3,000 ft/min

(P) Pressure Mode (V) Velocity Mode

0 0 to 25 Pa 0 0 to 2.5 m/s

1 0 to 50 Pa 1 0 to 5 m/s

2 0 to 100 Pa 2 0 to 10 m/s

3 0 to 250 Pa 3 0 to 15 m/s

4 0 to 25 Pa 4 0 to 2.5 m/s

5 0 to 50 Pa 5 0 to 5 m/s

6 0 to 100 Pa 6 0 to 10 m/s

7 0 to 250 Pa 7 0 to 15 m/s

Range 2 Model, Field Selectable (WC / ft/min or Pa / m/s)

(P) Pressure Mode (V) Velocity Mode

0 0 to 1 in. WC 0 0 to 3,000 ft/min

1 0 to 2.5 in. WC 1 0 to 4,000 ft/min

2 0 to 5 in. WC 2 0 to 5,000 ft/min

3 0 to 10 in. WC 3 0 to 6,000 ft/min

4 0 to 1 in. WC 4 0 to 3,000 ft/min

5 0 to 2.5 in. WC 5 0 to 4,000 ft/min

6 0 to 5 in. WC 6 0 to 5,000 ft/min

7 0 to 10 in. WC 7 0 to 6,000 ft/min

(P) Pressure Mode (V) Velocity Mode

0 0 to 250 Pa 0 0 to 15 m/s

1 0 to 500 Pa 1 0 to 20 m/s

2 0 to 1,000 Pa 2 0 to 25 m/s

3 0 to 2,500 Pa 3 0 to 30 m/s

4 0 to 250 Pa 4 0 to 15 m/s

5 0 to 500 Pa 5 0 to 20 m/s

6 0 to 1,000 Pa 6 0 to 25 m/s

7 0 to 2,500 Pa 7 0 to 30 m/s

Rotary Switch Settings (cont.)

Range 5 Model, Field Selectable (P) Pressure or (V) Velocity Mode,

Field Selectable (WC / ft/min or Pa / m/s)

(P) Pressure Mode (V) Velocity Mode

0 0 to 0.1 in. WC 0 0 to 500 ft/min

1 0 to 0.25 in. WC 1 0 to 1,000 ft/min

2 0 to 0.5 in. WC 2 0 to 2,000 ft/min

3 0 to 1 in. WC 3 0 to 3,000 ft/min

4 0 to 2.5 in. WC 4 0 to 4,000 ft/min

5 0 to 5 in. WC 5 0 to 5,000 ft/min

6 0 to 10 in. WC 6 0 to 6,000 ft/min

7 0 to 10 in. WC 7 0 to 7,000 ft/min

(P) Pressure Mode (V) Velocity Mode

0 0 to 25 Pa 0 0 to 2.5 m/s

1 0 to 50 Pa 1 0 to 5 m/s

2 0 to 100 Pa 2 0 to 10 m/s

3 0 to 250 Pa 3 0 to 15 m/s

4 0 to 500 Pa 4 0 to 20 m/s

5 0 to 1,000 Pa 5 0 to 25 m/s

6 0 to 2,500 Pa 6 0 to 30 m/s

7 0 to 2,500 Pa 7 0 to 35 m/s

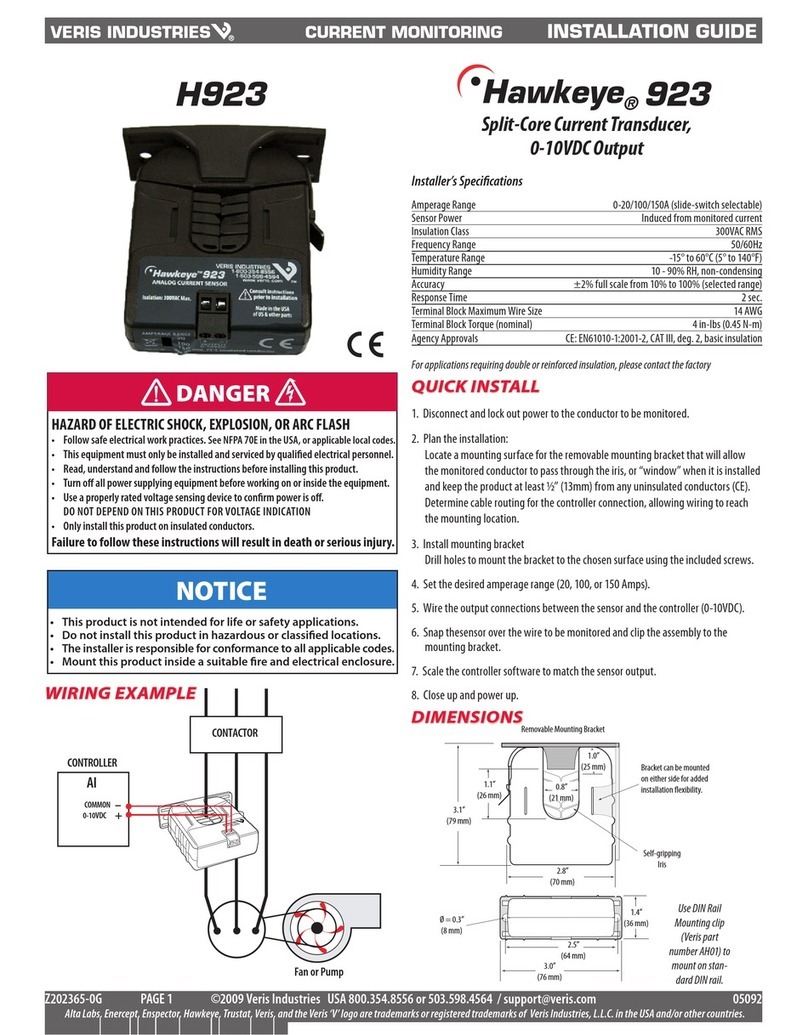

1/2-inch NPT female threaded coupler

5. For applications using conduit, remove the cable gland nut on the bottom of the

unit. Thread a standard 1/2-inch NPT female threaded coupler onto the body of the

cable gland. Connect the opposite end of the coupler to the conduit.

3-wire, 0-5 V/0-10 V Voltage Output

1.000

0

1

2

3

4

5

6

7

{

RMT. ZERO

ZERO

DIGITAL CONTROL

Digital

Output

V IN

-

POWER SOURCE

24 VAC/DC

-

+

V+/PWR

V-/GND

VOUT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Changes or modications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

Cet appareil est conforme aux normes d’exemption de licence RSS d’Industry Canada. Son fonctionnement

est soumis aux deux conditions suivantes : (1) cet appareil ne doit pas causer d’interférence et (2) cet appareil

doit accepter toute interférence, notamment les interférences qui peuvent aecter son fonctionnement.