Veris Industries PWXN07C User manual

Other Veris Industries Transducer manuals

Veris Industries

Veris Industries PH Series User manual

Veris Industries

Veris Industries Hawkeye H720 User manual

Veris Industries

Veris Industries PWR Series User manual

Veris Industries

Veris Industries H622-20 User manual

Veris Industries

Veris Industries H623-10 User manual

Veris Industries

Veris Industries ENERCEPT H8035 User manual

Veris Industries

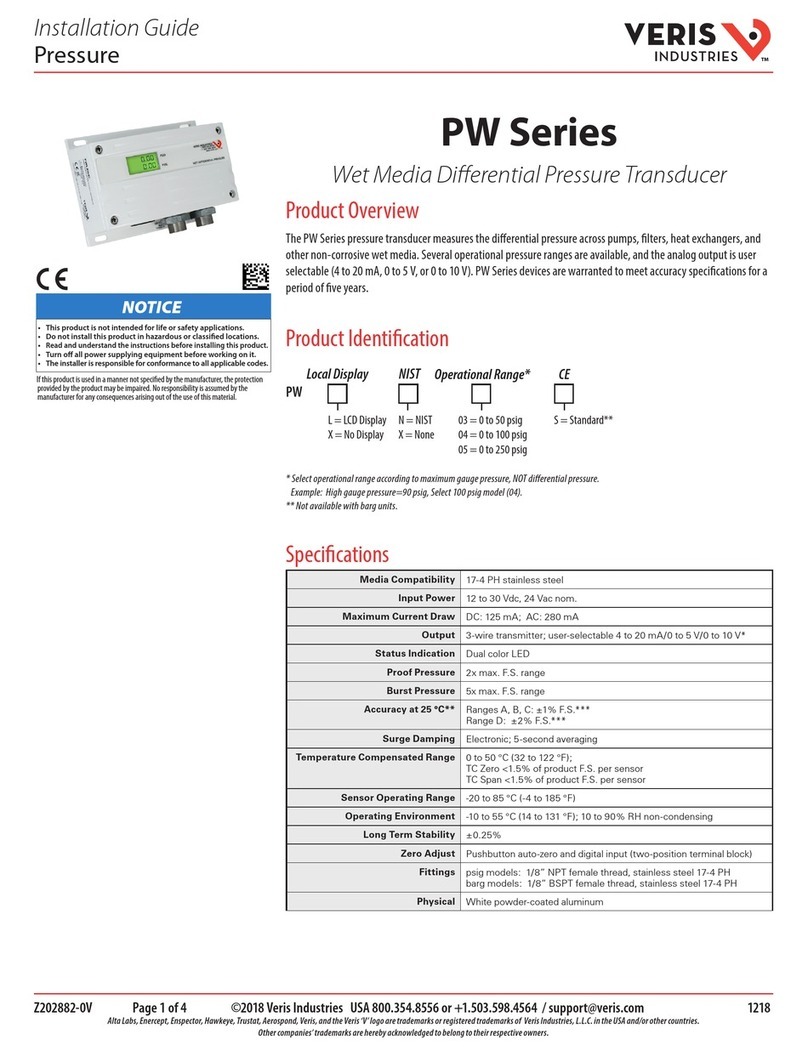

Veris Industries PW Series User manual

Veris Industries

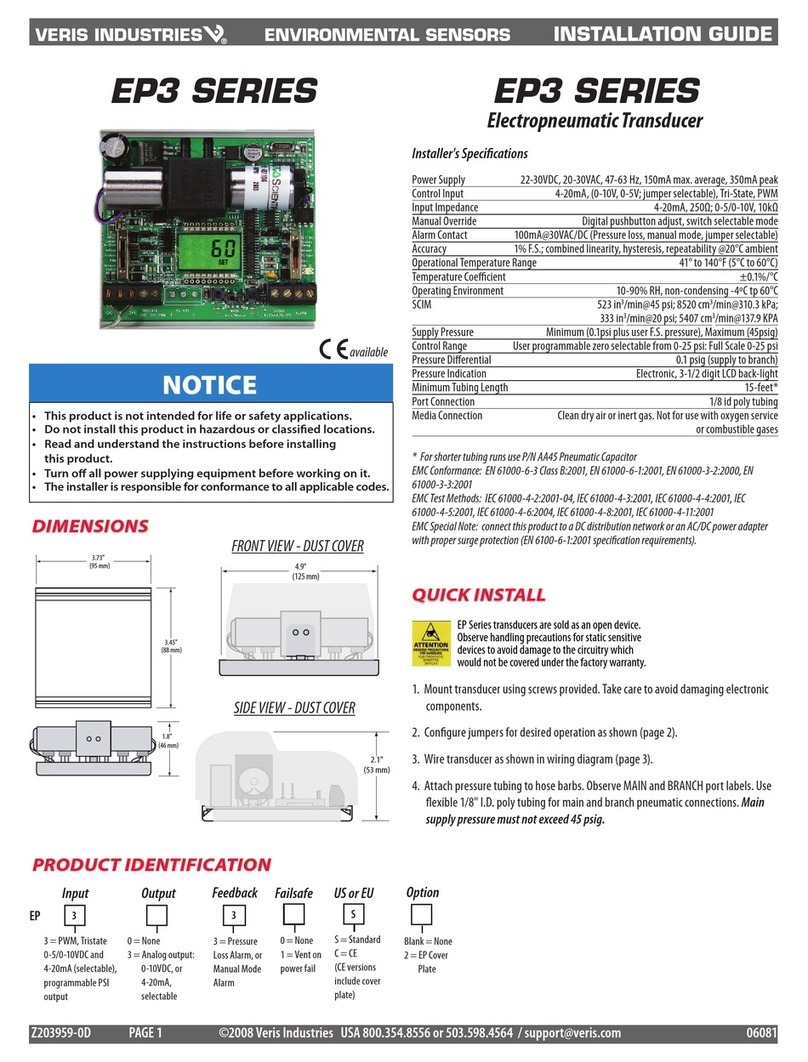

Veris Industries EP3 Series User manual

Veris Industries

Veris Industries PW2 Series User manual

Veris Industries

Veris Industries PW Series User manual

Popular Transducer manuals by other brands

Spirax Sarco

Spirax Sarco ITV1030 Installation and maintenance instructions

MAMAC SYSTEMS

MAMAC SYSTEMS PR-243 technical information

Balluff

Balluff BTL5-P user guide

MKS

MKS MicroPirani 925 Series Short form manual

WIKA

WIKA WU-20 operating instructions

Alcatel Vacuum Technology

Alcatel Vacuum Technology BARATRON 622A instruction manual