098D 201910

7

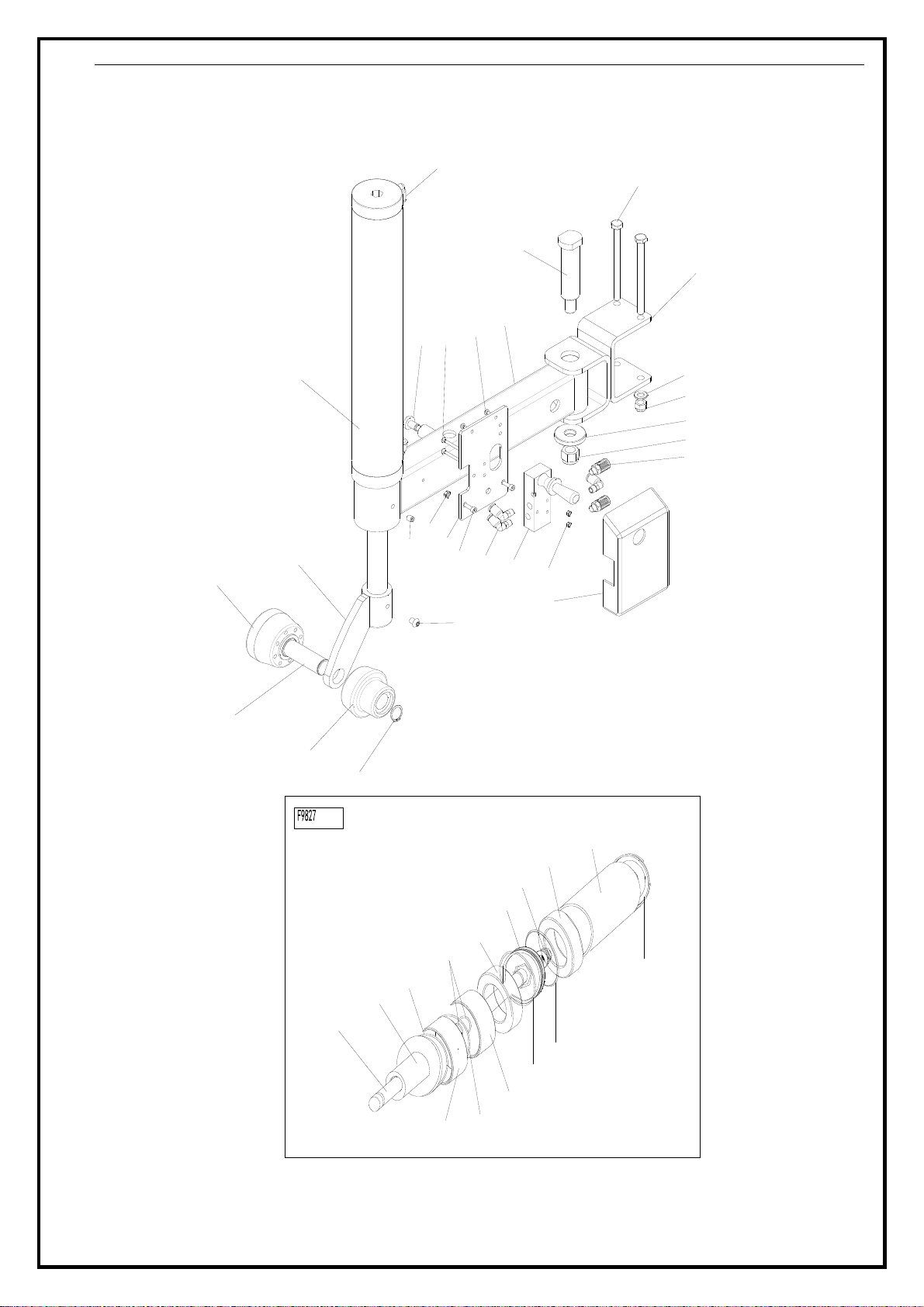

3. Nearby demounting/mounting head, insert lift lever N into tyre,use lift lever to lift bead upon

knob of demounting / mounting head. Manually rotate roller C to inner side,pull handle D down,

make roller C to press rim,keep 3-5mm gap between demounting/mounting head and rim, make

sure demounting/mounting head not damage rim, rotate turntable, demount tyre upper bead ( Fig 8).

4. Push handles D up, lift tire pressing roller assembly, loosen right pressing arm.

Lift tyre up, insert lifting level into bottom tyre bead nearby demounting/mounting head, lift bead

upon knob of demounting / mounting head and rotate turntable to demount down tyre bead.

c.Mount tyre

1. Lubricate tyre and rim edge with lubricant to avoid damage of tyre. Adjust height of

demounting/mounting head and make tyre bottom bead upon rear of demounting/mounting head and

below front of demounting/mounting head. Rotate turntable to mount bottom bead.

2. Make tyre top bead upon rear of demounting/mounting head and below front of

mounting/mounting head, move right pressing arm and make sure it is locked, pull handle D down to

make tire pressing roller assembly to press top bead to position below demounting/mounting head.

Lock tyre pressing head of 098D help arm on rim edge, rotate turntable, finish tyre mounting (Fig 10).

6. Maintenance:

Caution: please disconnect the machine from electric power supply and pneumatic power

supply.

Caution: only the professional persons can do the maintenance. To prolong the machine's life,

maintain the machine timely according to the manual. Otherwise, it will impact the reliability of the

machine or even cause injury to operator and others nearby.

Caution: before performing any maintenance, disconnect the tyre changer from the electric

power supply and pneumatic power supply, and tread the Jaws open and close Pedal or Turntable

Rotation Pedal for 3~4 times to evacuate all compressed air from the machine. Damaged parts must

be replaced by professional persons with the spare parts provided by manufacturer.

The specific maintenance please refers to the corresponding section of the tyre changer. If

there are any questions, please contact the manufacturer.

Trouble shooting table:

Note: In order to ensure the rise-fall control valve and the cylinder are reliable, the rise-fall

control valve should kept clean; the following instructions can be maintained.

The

Bead Breaker

shovel

operates

difficultly.

Jammed silencer Clean it or replace it.

The seal rings on the Bead Breaker

cylinder are broken. Replace it.

Leakage of Air network Check all the parts on

the air network.

The rise-fall control valve is broken. Replace it.