TABLE OF CONTENTS

1.

INTRODUCTION ............................................................................................................................................................................................. 3

2.

PROTOCYCLER LAYOUT ............................................................................................................................................................................. 3

3.

IMPORTANT LIMITATIONS ....................................................................................................................................................................... 2

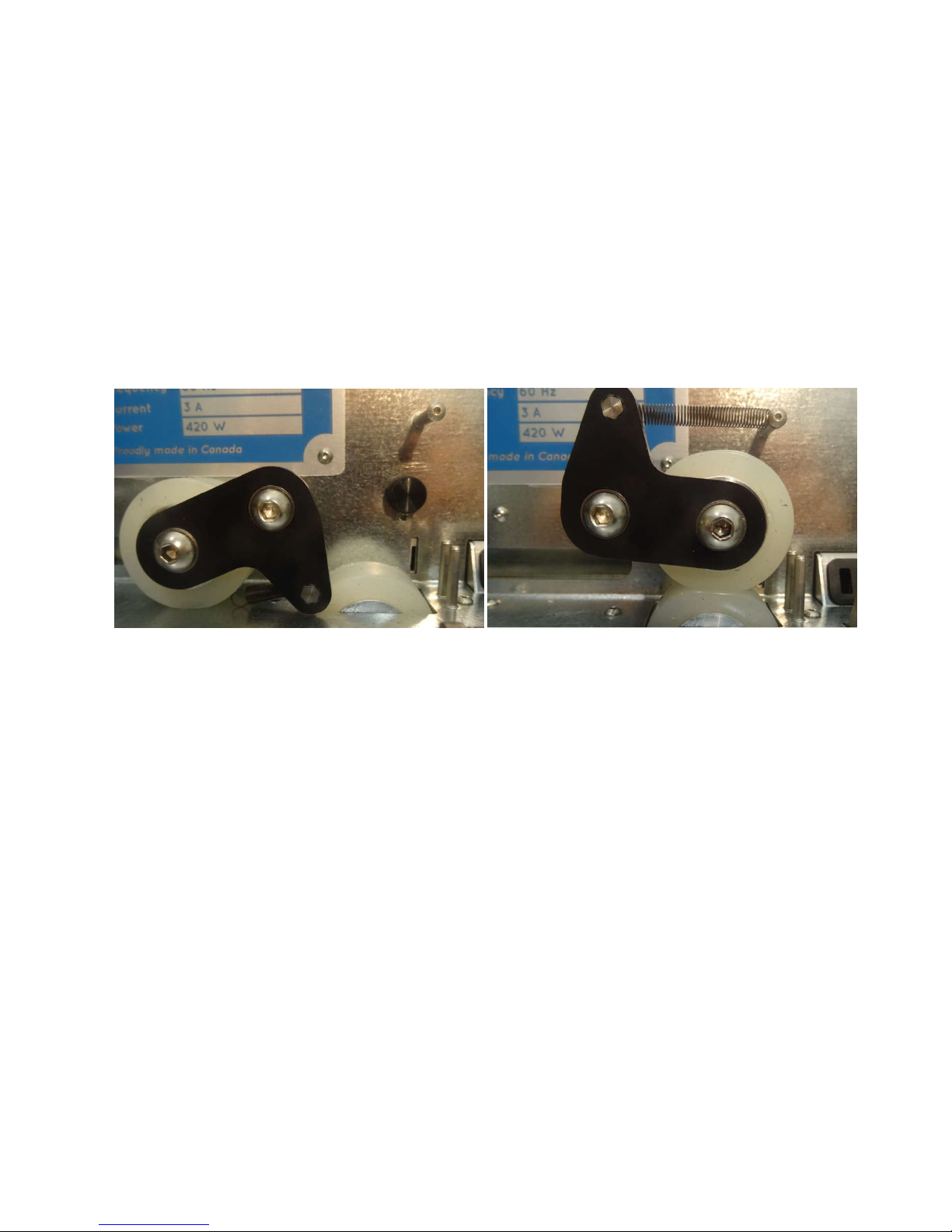

3.1.

P

ULLER

W

HEELS

S

QUISHING

............................................................................................................................................................... 2

3.2.

C

OLORED

VS

T

RANSPARENT

P

LASTIC

.................................................................................................................................................... 2

3.3.

D

RY

VS

W

ET

P

LASTIC

........................................................................................................................................................................ 3

3.4.

R

EGRIND

S

IZE

&

E

XTRUDING

R

ECYCLED

P

LASTIC

..................................................................................................................................... 4

3.5.

A

MBIENT

T

EMPERATURE

.................................................................................................................................................................... 4

4.

EXTRUSION ..................................................................................................................................................................................................... 5

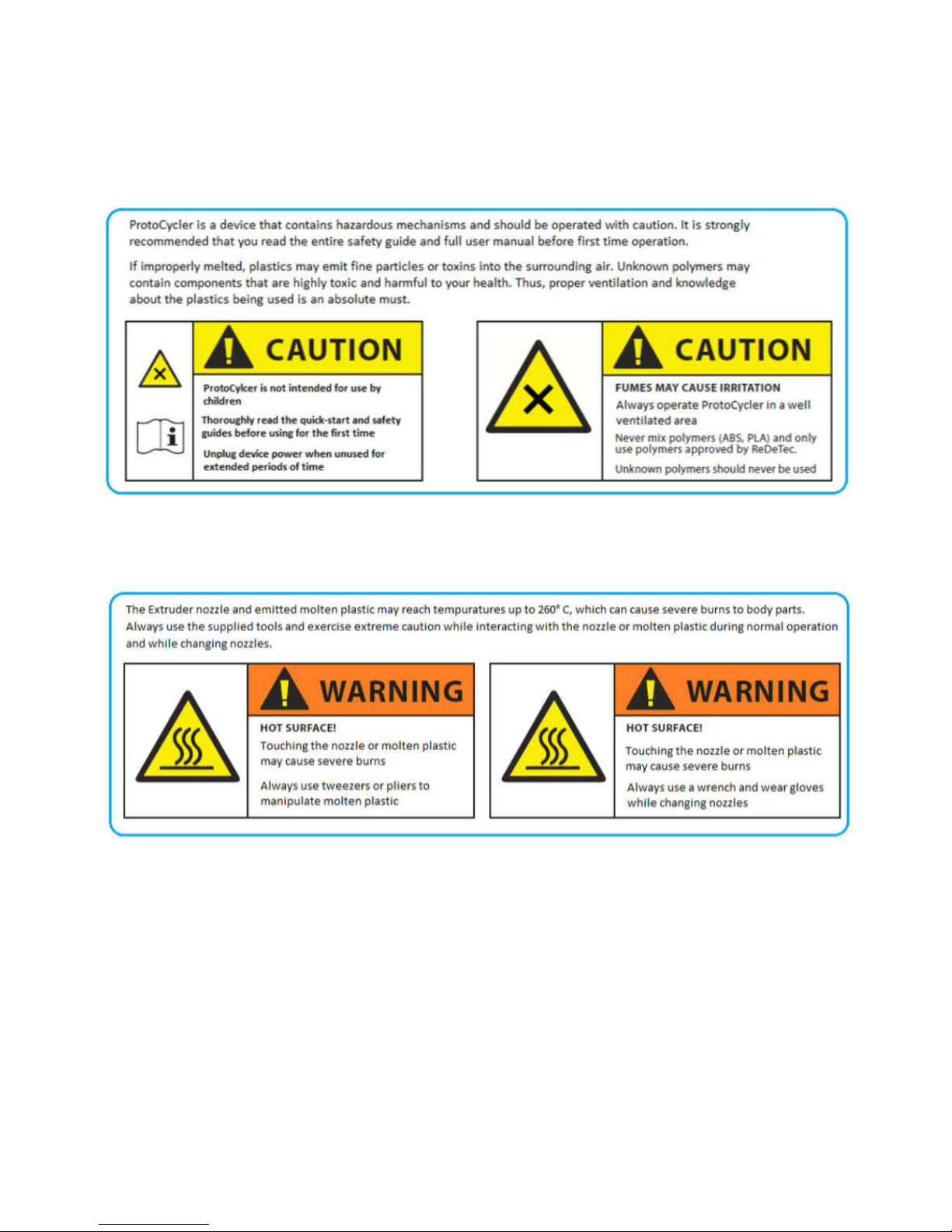

4.1.

S

AFETY

O

VERVIEW

............................................................................................................................................................................ 5

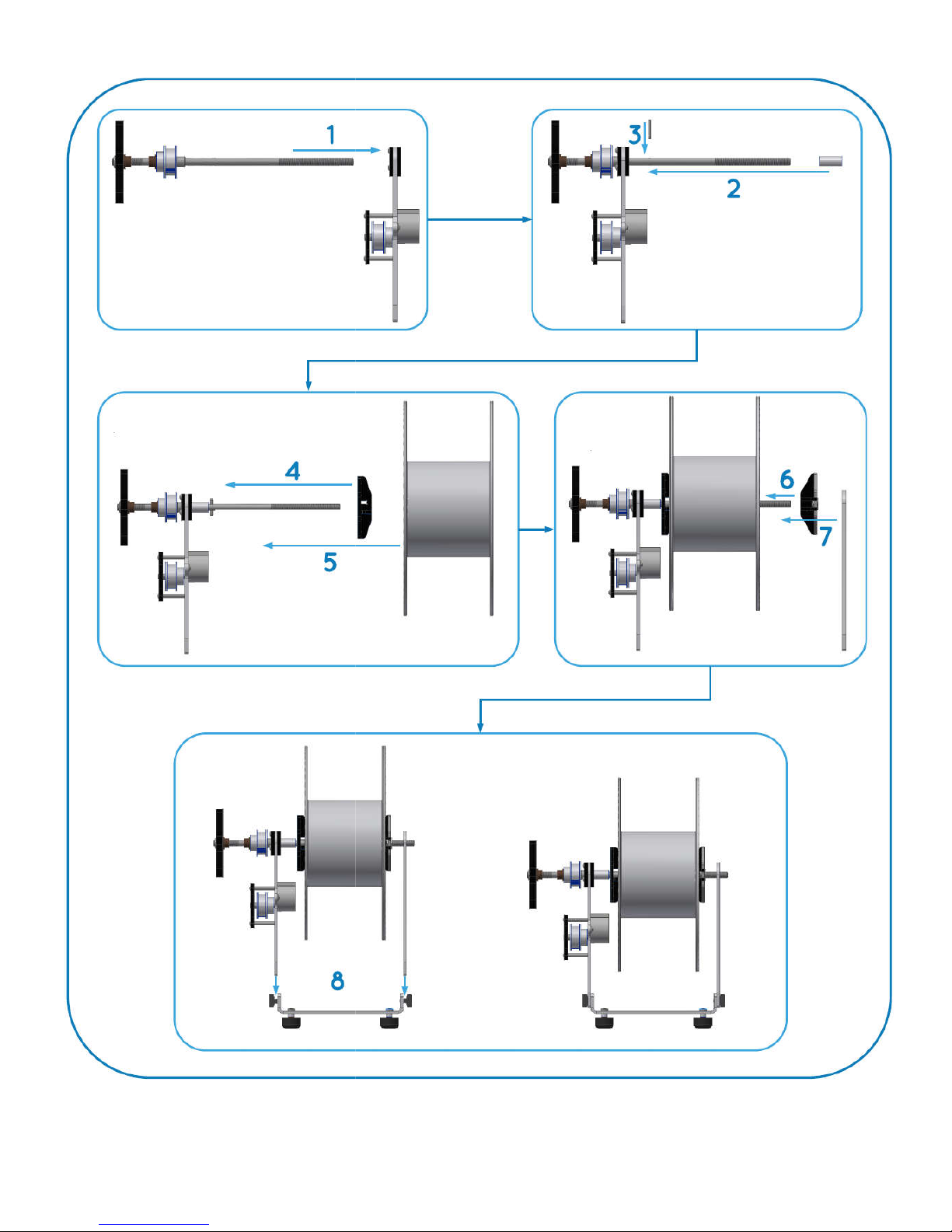

4.2.

S

POOLER

S

ETUP

............................................................................................................................................................................... 6

4.3.

A

UTOMATIC

E

XTRUSION

.................................................................................................................................................................... 8

4.4.

S

POOLER

C

LUTCH

T

ENSION

A

DJUSTMENT

............................................................................................................................................ 10

4.5.

M

ANUAL

E

XTRUSION

(A

DVANCED

) .................................................................................................................................................... 10

4.6.

E

XTRUDER

N

OZZLE

R

EMOVAL

/

R

EPLACEMENT

..................................................................................................................................... 14

5.

GRINDER OPERATION ............................................................................................................................................................................... 15

5.1.

S

AFETY

O

VERVIEW

.......................................................................................................................................................................... 15

5.2.

F

IRST

T

IME

S

ETUP

........................................................................................................................................................................... 15

5.3.

O

PERATION

................................................................................................................................................................................... 15

5.4.

S

ORTING

G

ROUND

M

ATERIAL

........................................................................................................................................................... 16

6.

TROUBLESHOOTING .................................................................................................................................................................................. 16