Canada EMC

This spark ignition system complies with the Canadian

standard ICES-002.

Product liability

As referred to in the product liability laws, we are not

liable for damages that our product causes if:

• the product is incorrectly repaired.

• the product is repaired with parts that are not from

the manufacturer or not approved by the

manufacturer.

• the product has an accessory that is not from the

manufacturer or not approved by the manufacturer.

• the product is not repaired at an approved service

center or by an approved authority.

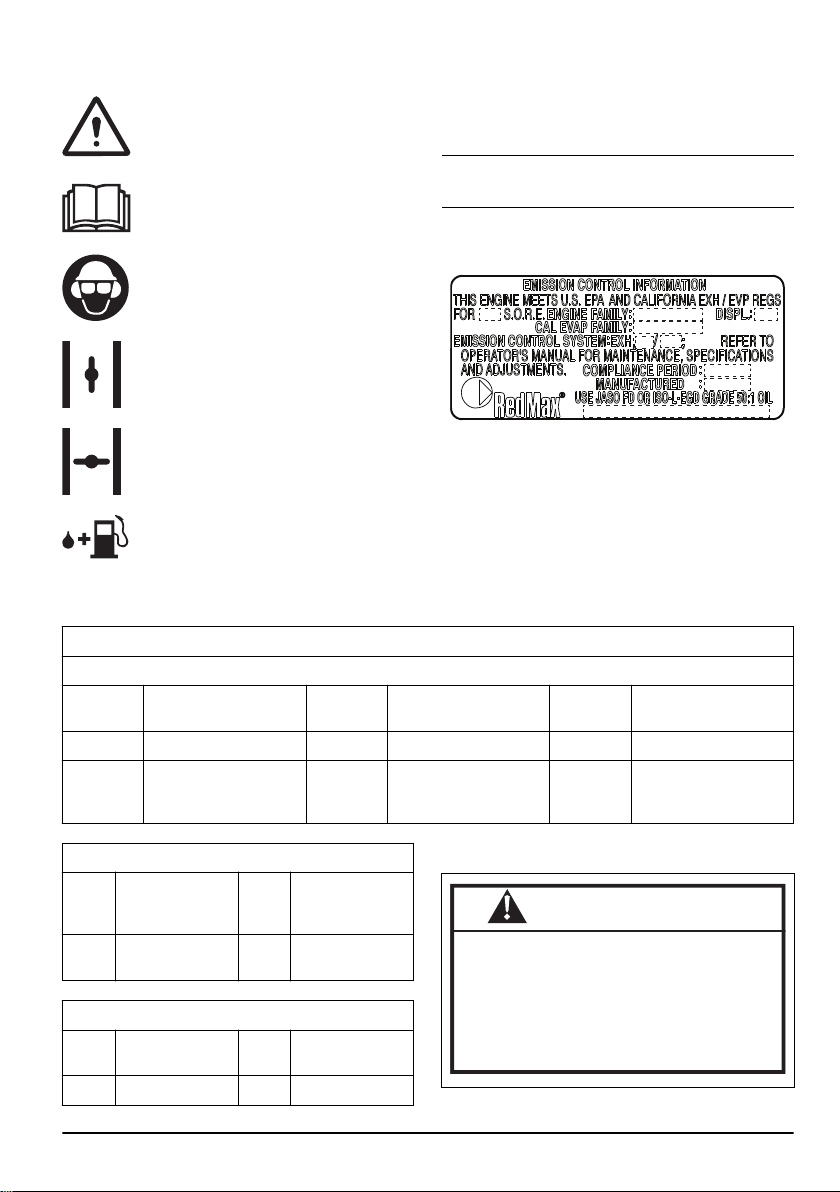

Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of

injury or death for the operator or bystanders

if the instructions in the manual are not

obeyed.

CAUTION: Used if there is a risk of

damage to the product, other materials or

the adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary

in a given situation.

General safety instructions

WARNING: Read the warning

instructions that follow before you use the

product.

• Incorrect or careless use of the product can turn it

into a dangerous tool that can cause serious or even

fatal injury. It is extremely important that you read

and understand the contents of this operator’s

manual.

• This product produces an electromagnetic field

during operation. This field may under some

circumstances interfere with active or passive

medical implants. To reduce the risk of serious or

fatal injury, we recommend persons with medical

implants to consult their physician and the medical

implant manufacturer before operating this product.

• Overexposure to vibration can lead to circulatory

damage or nerve damage in people who have

impaired circulation. Contact your doctor if you

experience symptoms of overexposure to vibration.

Such symptoms include numbness, loss of feeling,

tingling, pricking, pain, loss of strength, changes in

skin color or condition. These symptoms normally

appear in the fingers, hands or wrists. The risk

increases at low temperatures.

• If you encounter a situation where you are uncertain

how to proceed you should ask an expert. Contact

your dealer or your service workshop. Avoid all

usage which you consider to be beyond your

capability.

• Keep in mind that the operator is responsible for

accidents or hazards occurring to other people or

their property.

• Never allow anyone else to use the product without

first ensuring that they have understood the contents

of the operator’s manual.

• Never allow children to use or be in the vicinity of the

product. As the product is equipped with a spring-

loaded stop switch and can be started by low speed

and force on the starter handle, even small children

under some circumstances can produce the force

necessary to start the product. This can mean a risk

of serious personal injury. Therefore remove the

spark plug cap when the product is not under close

supervision.

• Store the product out of reach of children.

• Never use the product if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgement or your

coordination.

• Never use a product that is faulty. Carry out the

checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. Refer to instructions under the

heading Maintenance.

• Never use a product that has been modified in any

way from its original specification.

Safety instructions for operation

WARNING: Read the warning

instructions that follow before you use the

product.

• Never use the product in extreme weather conditions

such as severe cold, very hot and/or humid climates.

• Faulty blades can increase the risk of accidents.

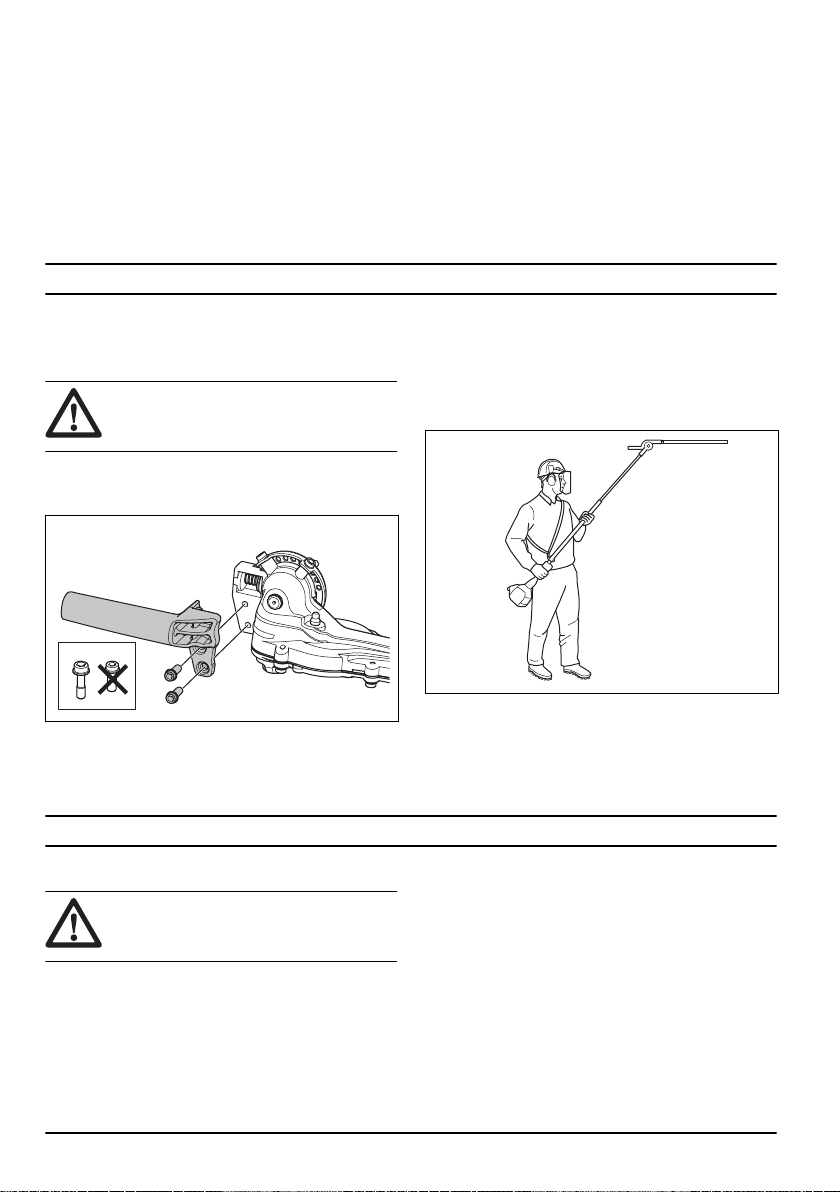

• Ensure that no people or animals comes closer than

15 m / 50 ft while you work.

• Observe your surroundings and make sure that there

is no risk of people or animals coming into contact

with the cutting equipment.

41695 - 001 - 24.06.2021