4

■In order to ensure proper and safe

operation of your power auger

•Read this Owner/Operator Manual

carefully. Be sure you understand how

to operate this unit properly before you

use it. Failure to do so could result in

serious injury.

•Be sure to keep this manual handy so

that you may refer to it later whenever

any questions arise. Also note that you

are requested to contact the dealer from

whom you purchased the product for

assistance in the event that you have

any questions which cannot be

answered herein.

•Always be sure to include this manual

when selling, lending, or otherwise

transferring the ownership of this

product.

•This product has been designed for use in

earth drilling, and it should never be used

for any other purpose since doing so

could result in unforeseen accidents and

injuries occurring.

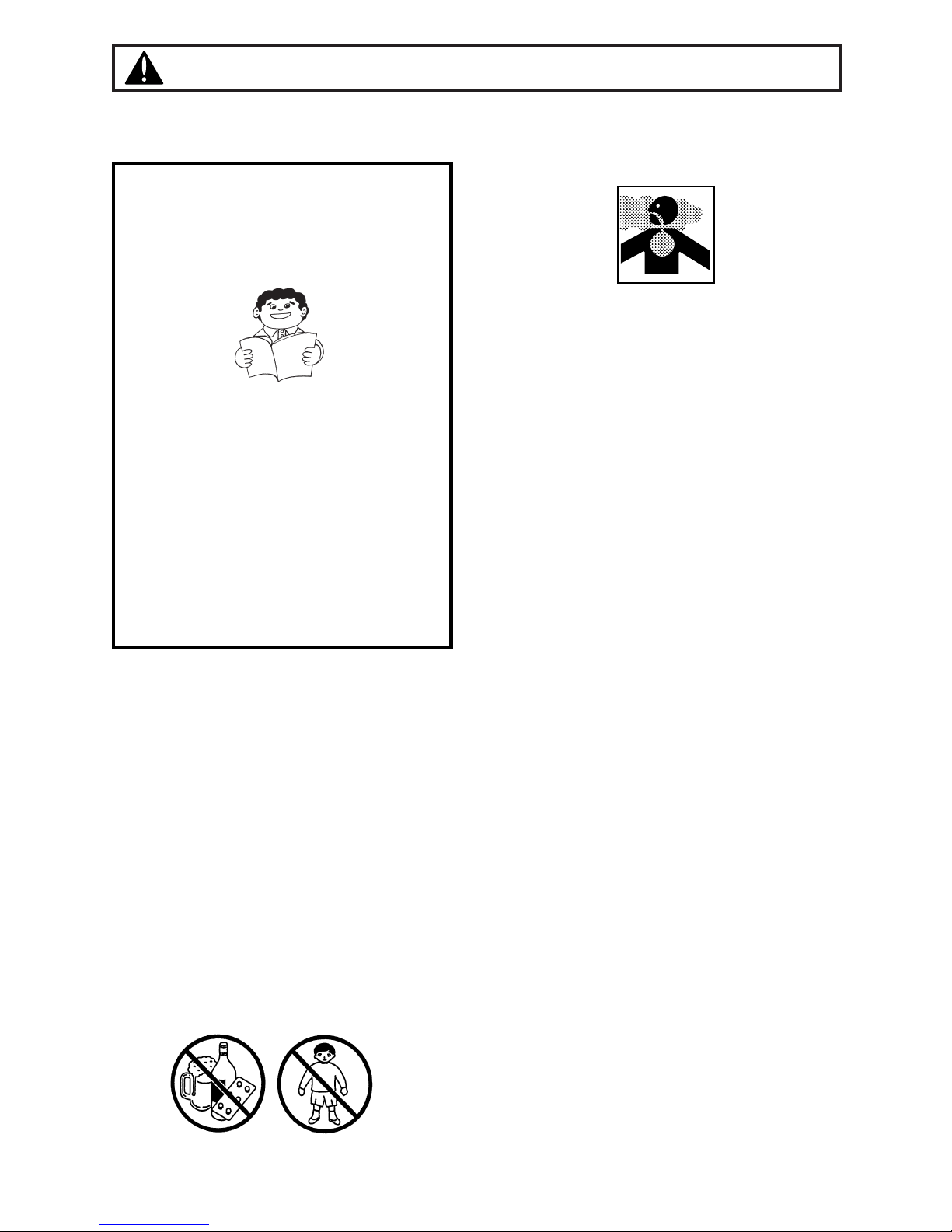

•You should never use this power auger

when under the influence of alcohol, when

suffering from exhaustion or lack of sleep,

when suffering from drowsiness as a

result of having taken cold medicine, or at

any other time when a possibility exists

that your judgment might be impaired or

that you might not be able to operate the

power auger properly and in a safe

manner. Also be sure never to allow

children or anyone unable to fully

understand the directions given in this

manual to use this power auger.

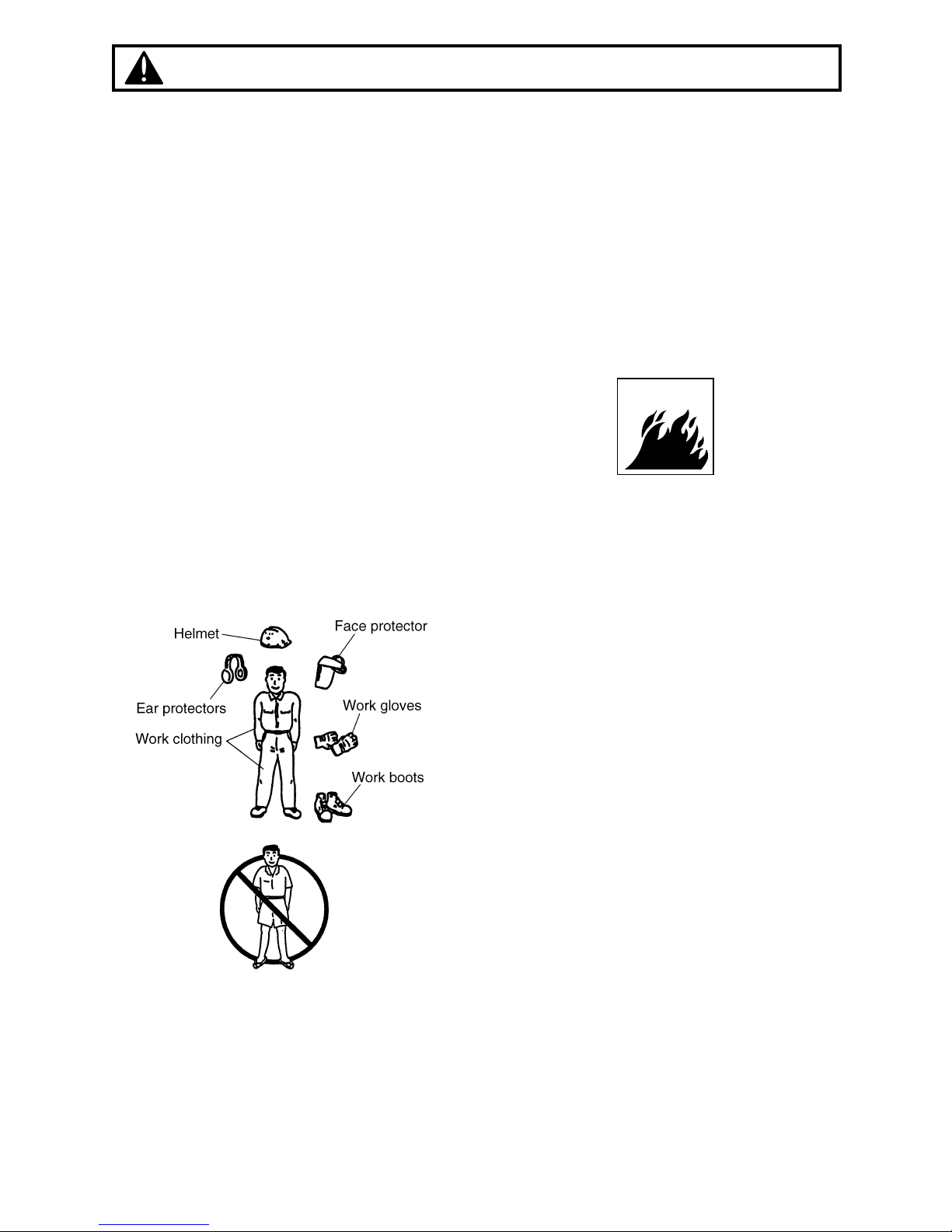

1. Safety Precautions

•Avoid running the engine indoors. The

exhaust gases contain harmful carbon

monoxide.

•Never use your power auger under

circumstances like those described below:

1. When the ground is slippery or when

other conditions exist which might

make it not possible to maintain a

steady posture while using the power

auger.

2. At night, at times of heavy fog, or at any

other times when your field of vision

might be limited and it would be difficult

to gain a clear view of the area where

the power auger is to be used to ensure

safety.

3. During rain storms, during lightning

storms, at times of strong or gale-force

winds, or at any other times when

weather conditions might make it

unsafe to use this product.

•When using this product for the first time,

before beginning actual work, take the

power auger to a wide, clear, open space,

turn on the power, and practice handling

the power auger until you are sure that

you will be able to handle in it properly in

actual operation.

•Lack of sleep, tiredness, or physical

exhaustion results in lower attention

spans, and this in turn leads to accidents

and injury. When planning your work

schedule, allow plenty of time to perform

the work of cutting and allow plenty of

time for rest. Limit the amount of time

over which the power auger is to be used

continuously to somewhere around 30~40

minutes per session, and take 10~20

minutes of rest between work sessions.

Also try to keep the total amount of work

performed in a single day under 2 hours

or less.