M003 Issue: 1.5 Created by: Technical Dept. 5 February 2020

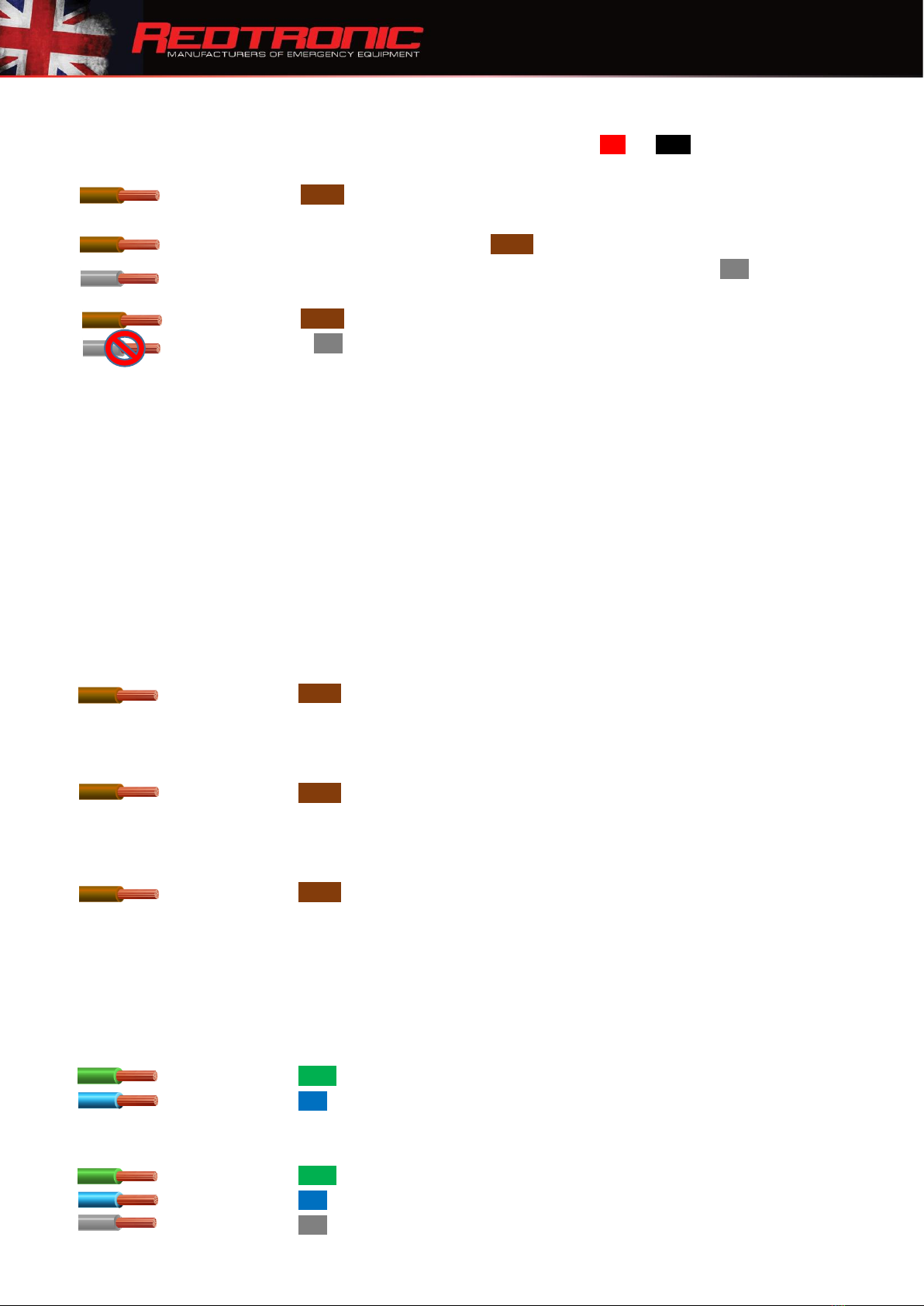

5.2 Alley Lights –‘Permanent on’ or ‘Flash’

a) Ensure the Lightbar is in ‘Standby’ mode by connecting Red +ve Black -ve

b) Apply the Alley Left & Alley Right input wires to +ve permanently

c) Apply the brown (Pattern Select) wire to +ve momentarily

d) The Alley Lights will now flash in an alternating pattern

e) To Revert to ‘Permanent on’ apply the brown (Pattern Select) wire to +ve momentarily

f) If wanting to use more than ‘alley light’ for illumination, simply Apply the grey

(Config) wire to +ve permanently

a) Apply the brown (Pattern Select) wire to +ve momentarily

b) Release the grey wire

Note: Changing Alley Lights to ‘Flash’ will not affect the pattern of the lightbar when it is

not selected

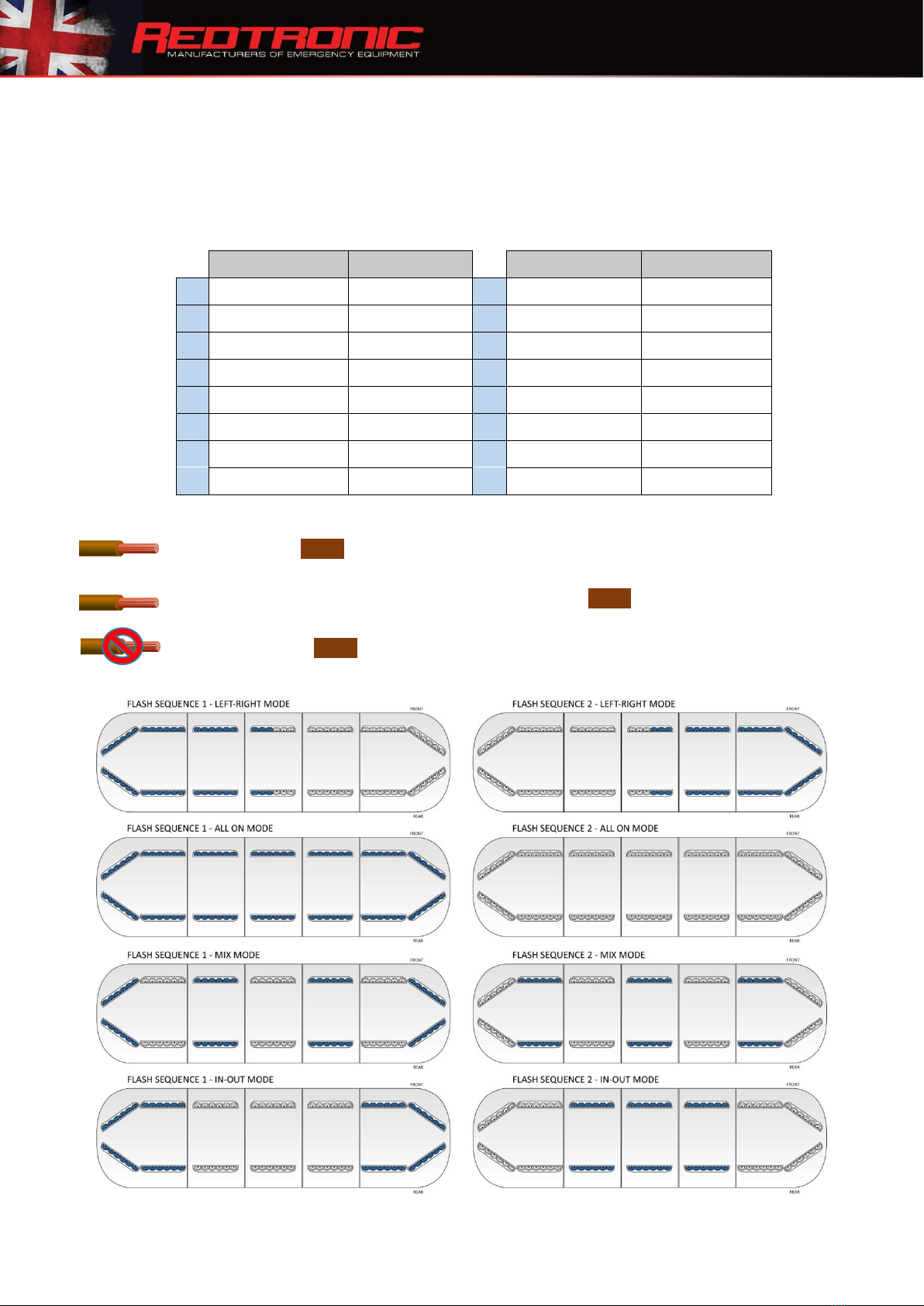

6.0 CAP168 / ICAO / CAA / ACAA (whilst in 360/1, 360/2, Cruise Mode, Rotate patterns) - (61fpm)

This function is built-in to the Cruise and Rotate flash patterns as standard. If you require it

on another wire, setting Dil Switch 2 to ‘ON’ gives the addition of CAP168 pattern (Airport

Mode) to the 360/1, 360/2 flash pattern options –in all 4 different flash modes (left-right,

all-on, mix, in-out). In addition, the colour can be individually set to each output (refer to 9.0

Setting the Colour)

6.1 360/1 & 360/2 Outputs

a) Ensure the Lightbar is in ‘Standby’ mode, set Dil Switch 2 to ‘ON’

b) Apply the input wire programmed as ‘360/2’ to +ve permanently

c) Apply the brown (Pattern Select) wire to +ve momentarily until CAP168 is enabled

6.2 Cruise Mode

a) Apply the input wire programmed as ‘Cruise Mode’ to +ve permanently

b) Apply the brown (Pattern Select) wire to +ve momentarily until CAP168 is enabled

6.3 Rotate

a) Apply the input wire programmed as ‘Rotate’ to +ve permanently

b) Apply the brown (Pattern Select) wire to +ve momentarily until CAP168 is enabled

7.0 Setting Dim Mode

There are two modes available with the Lightbar; 25% brightness and 50% of full brightness (default).

Dim does not apply to Stop/Tail/Indicator, Alley Lights, Worklamps or Front Floods.

a) Ensure the Lightbar is in ‘Standby’ mode

b) Apply the green (360/1) wire to +ve permanently

c) Apply the blue (Dim) wire to +ve permanently

d) Dim is now enabled at 50% of full brightness on all inputs

To decrease to 25% of full brightness: -

a) Apply the green (360/1) wire to +ve permanently

b) Apply the blue (Dim) wire to +ve permanently

c) Apply the grey (Config) wire to +ve permanently