Series RS7000 / RSTW7000 Hose Reels

Page 2 www.reelcraft.com

INSTALLATION INSTRUCTIONS

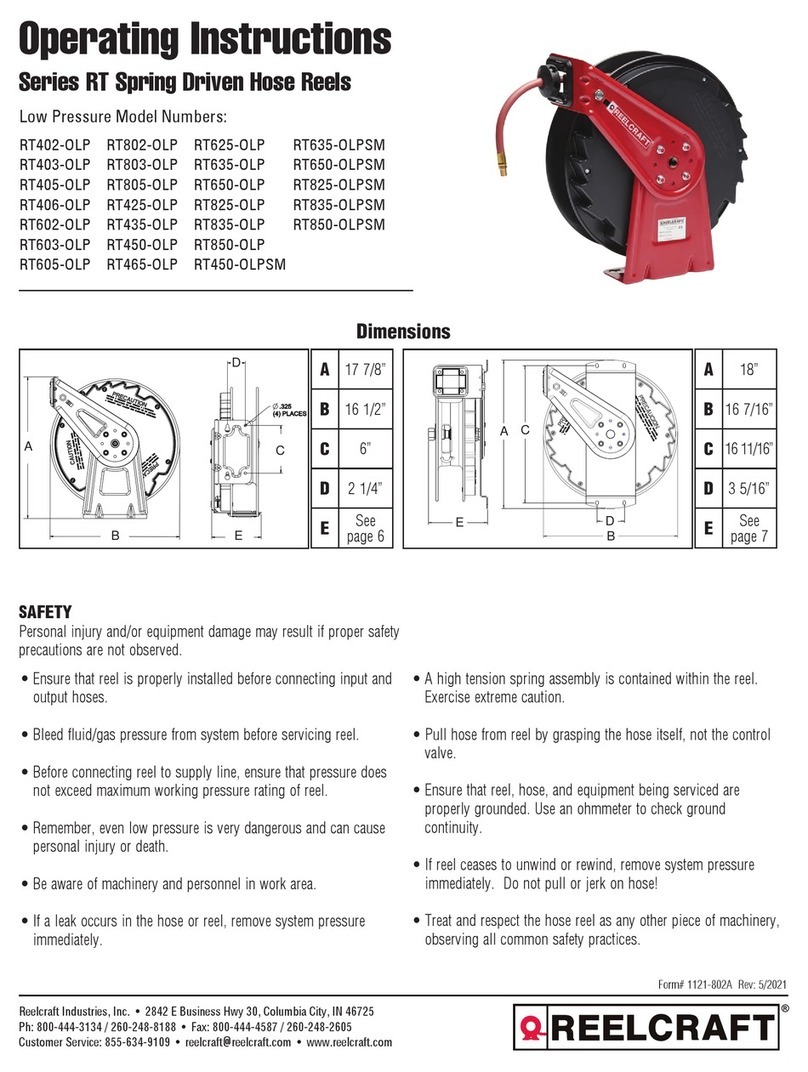

MOUNTING

Caution: Unless reel was specified differently when ordering,

maximum installation height is 16 feet. Do not exceed this

distance.

1. Unpack and inspect reel for damage. Turn by hand to check

for smooth operation. Check for completeness.

2. Configure reel for top, side or bottom-wind hose dispensing

by removing nuts (1) securing guide arm bracket (2). Position

guide arm bracket to desired location, and replace nuts.

Caution: When changing guide arm positions, the U-bolt

must be placed in the proper location as instructed in figure A

below. The reel can “latch out” during use if this instruction is

not adhered to.

3. Position reel on floor, wall, or ceiling. Secure into place using

four (customer supplied) bolts (3).

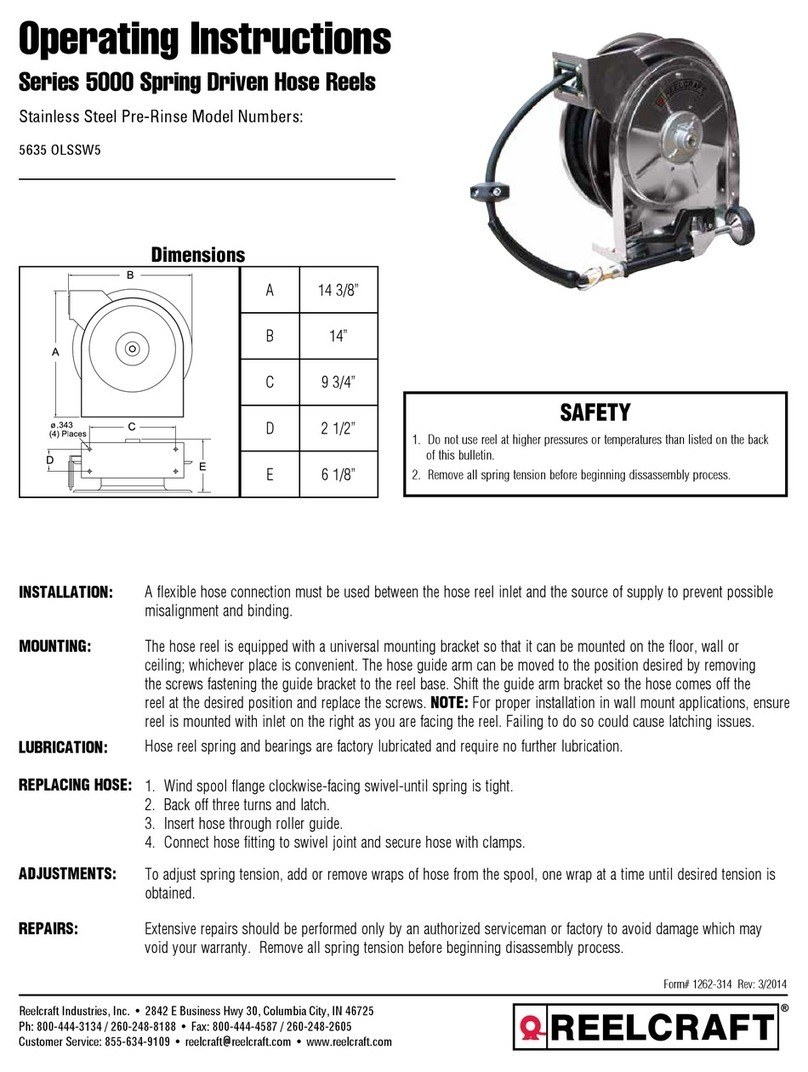

FOR NON-WELDING HOSE REELS (RS Models Only)

INSTALLING THE INPUT HOSE

Warning: Ensure that supply line pressure does not exceed

maximum working pressure rating of reel. Apply pipe thread

sealant to all threads. Caution: Use flexible hose connection at

input. Do not use rigid plumbing.

1. Connect supply line hose (4) to main shaft input (5) as

indicated in illustration.

INSTALLING THE OUTPUT HOSE (No Hose Model)

Warning: Use extreme caution; reel under tension. Avoid

releasing latch mechanism. Apply pipe thread sealant to all

threads.

1. Manually turn sheave (10) until spring is tight, back off 3

turns, then latch.

2. Route output hose (11) through guide arm bracket (2),

U-bolts (12), then through cutout (13) in spool as indicated in

illustration.

3. Connect output hose (11) to swivel (14) as indicated in

illustration.

4. Tighten U-bolts (12).

5. Charge inlet and outlet hoses. Momentarily open control valve

on working end to purge hoses of gases. When fluid appears

at control valve, close valve. With hoses fully charged, release

latch and wind output hose onto reel.

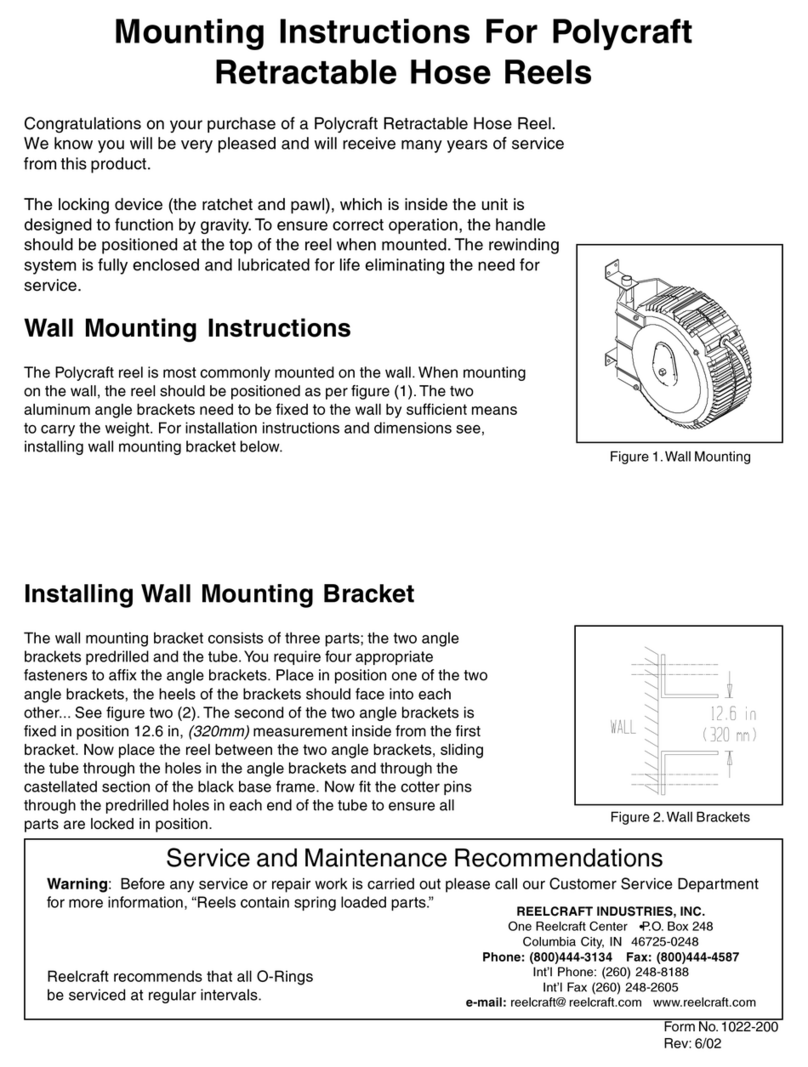

6. Install REELSAFE®hose identification sticker onto working

end of hose in a highly visible location. (Figure B)

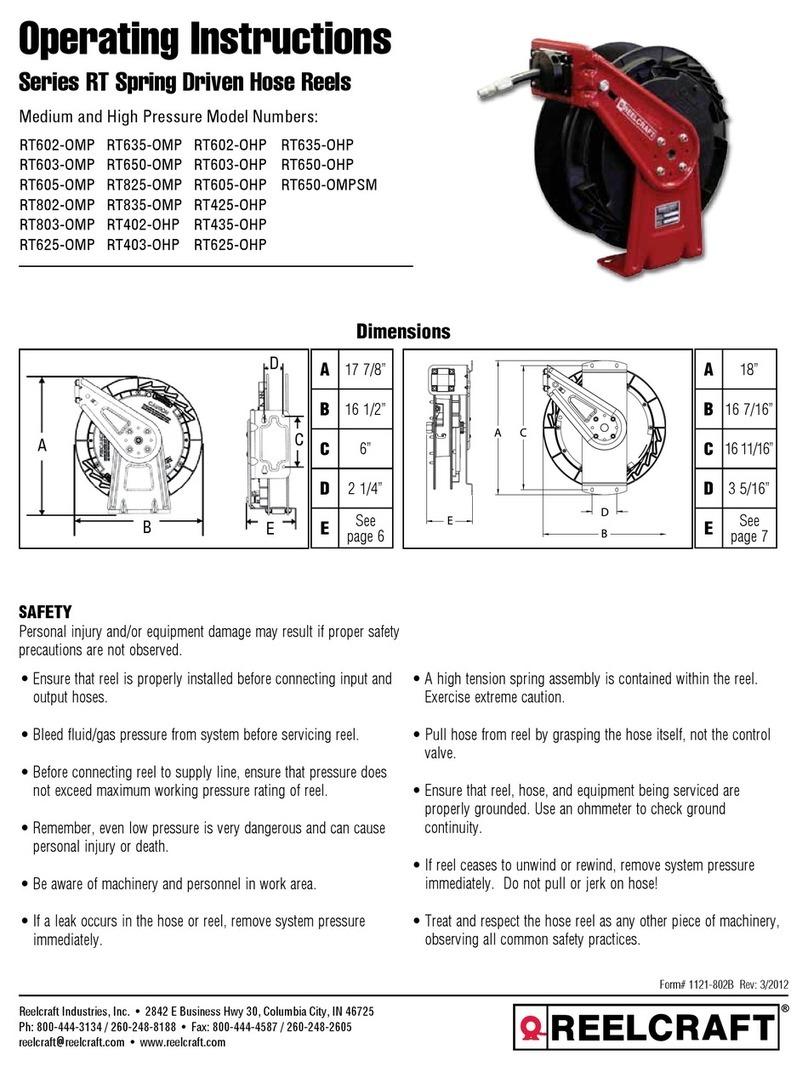

FOR WELDING HOSE REELS (RSTW Models Only)

INSTALLING THE INPUT HOSES

Caution: Apply thread sealant to all input connections to insure

a proper seal.

INSTALLING THE OUTPUT HOSES (No Hose Model)

Caution: Use extreme caution; reel under tension, avoid

releasing latch mechanism. Apply thread sealant to outlet

connections.

1. Manually turn spool assembly until spring is tight, back off

three turns, then latch.

2. Route output hoses through guide bracket.

3. Using a wrench, firmly hold on to output fittings on swivel

while tightening the hose connector.

4. Install REELSAFE®hose identification sticker onto working

end of the gas hose only in a highly visible location. (Figure

B)

11 15

2

13

4

12

2

10

14

1

5

3

Figure A

Acetylene/fuel gas

inlet 1/4” FPT

(Red)

Oxygen

inlet 1/4” FPT

(Green)

Figure B

Step 1 Step 2 Step 3