Series SW/TWHD70000 Welding Hose Reels

Page 2 www.reelcraft.com

IN-SERVICE CAUTION:

• The user is cautioned not to shut off the fuel gas at the

regulator or supply source first, as a flashback may result,

and thereby damage the hose.

• Users are cautioned specifically to shut off the gas at the

torch first, and then at the regulator or supply source, to

limit permeation of gas through the hose wall. This should

be done when the torch will not be used for periods in

excess of 30 minutes.

• After the flame has been extinguished and the gas turned off

at the supply source, it is recommended that any remaining

gas be bled to minimize degradation of the rubber during

long shutdowns.

• To prevent an accumulation or concentration of gas that

could be explosive or otherwise harmful to personnel, ade-

quate ventillation must be provided at all times, particularly

in confined areas where fuel gas is being used.

• Additional advice for minimizing the permeation problem has

been supplied by an NWSA member who states “The source

of gas (fuel gas and oxygen) should be closed before leav-

ing for the day or shift. After the cylinder or manifold valves

have been closed, the torch valves (both fuel gas and oxy-

gen) should be opened to remove all pressure from hoses.

INSTALLATION INSTRUCTIONS

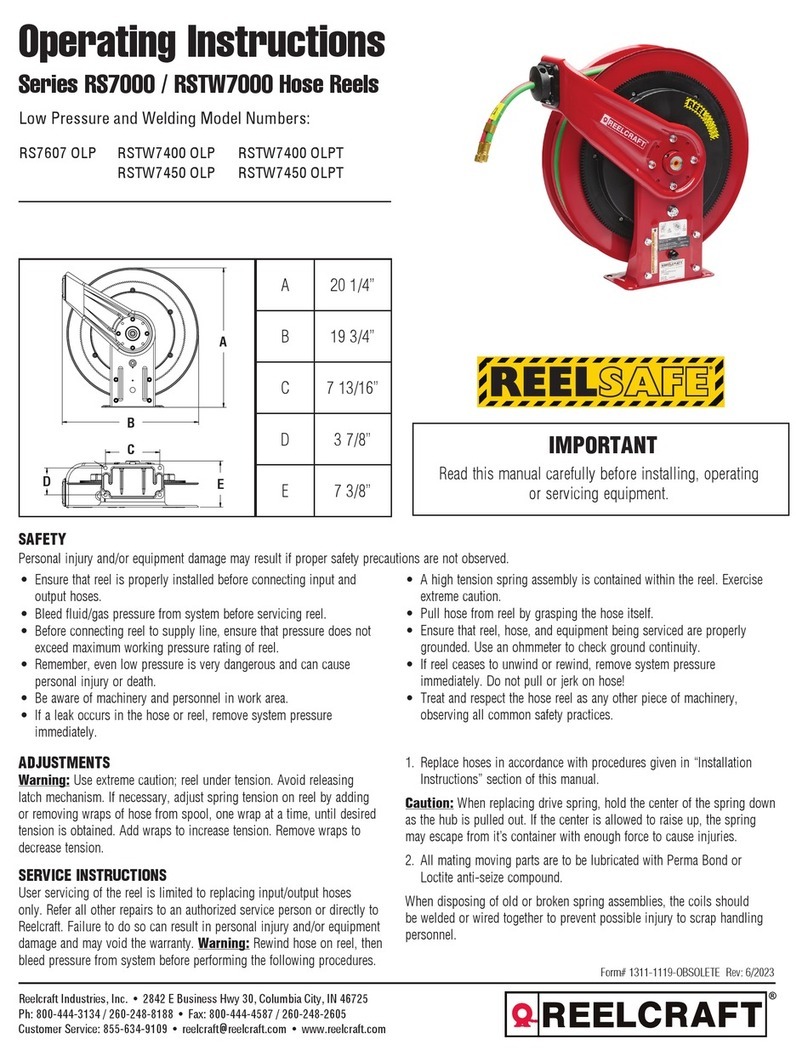

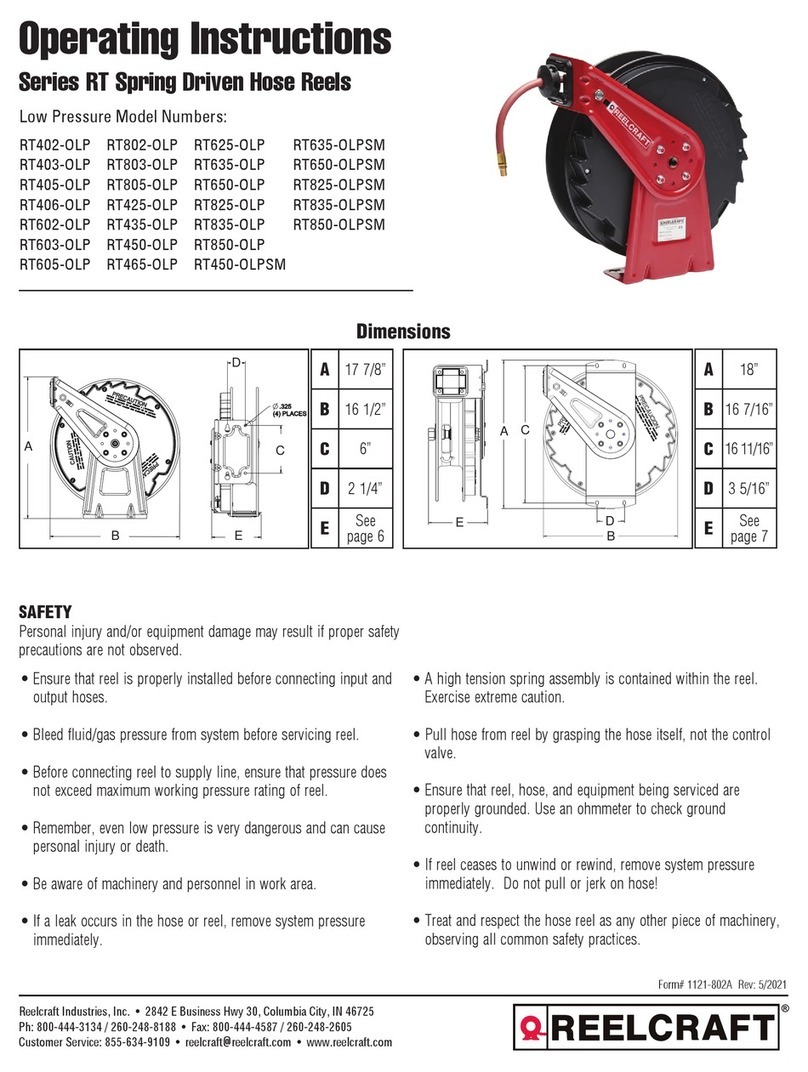

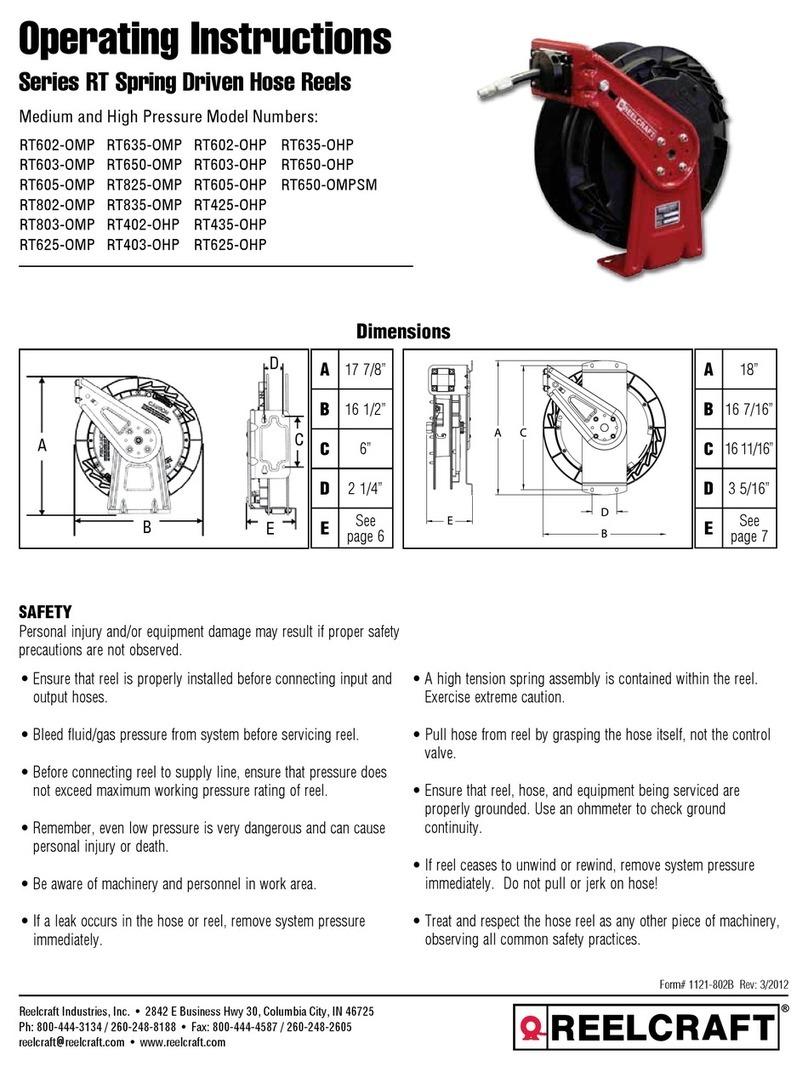

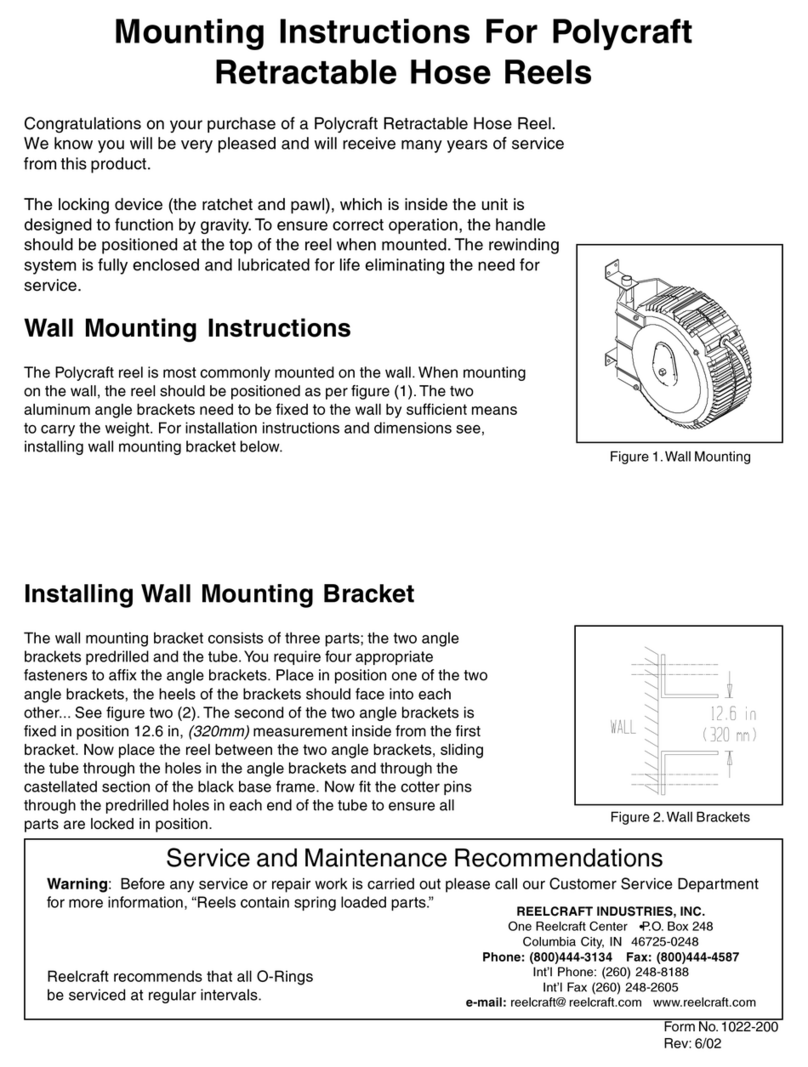

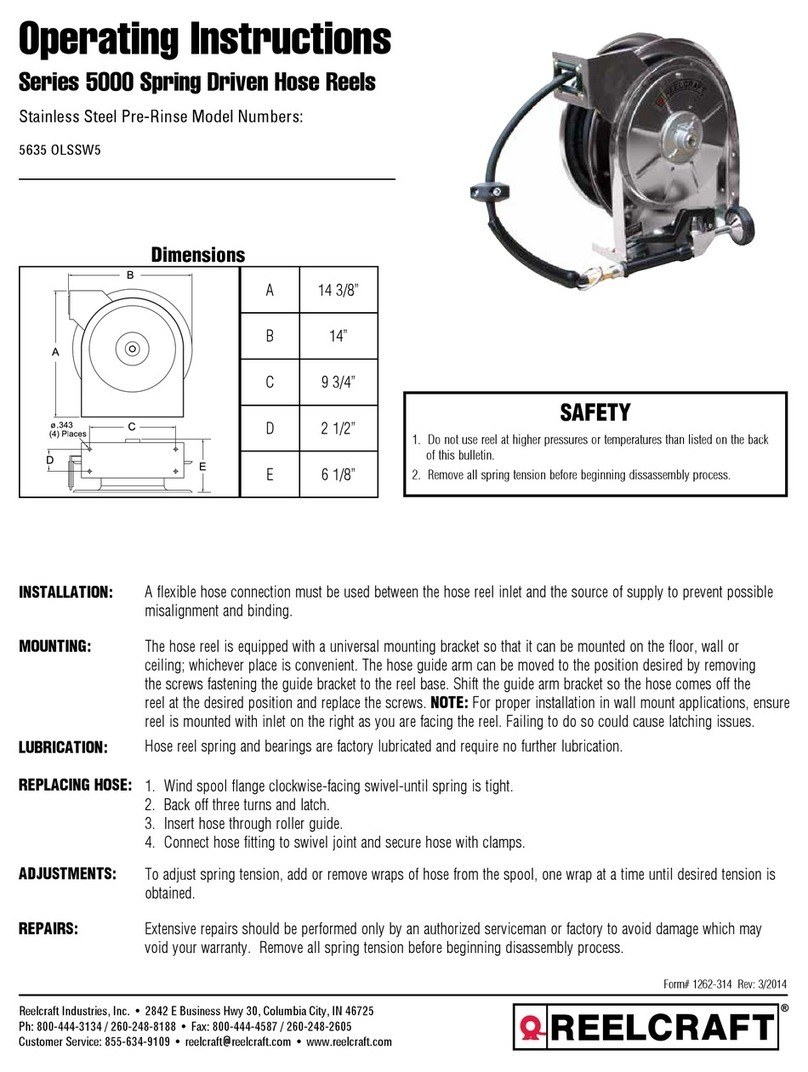

MOUNTING

Caution: Unless reel was specified differently when ordering,

maximum installation height is 16 feet. Do not exceed this dis-

tance. Observe all applicable NEC, OSHA & local codes when

installing this equipment.

1. Unpack and inspect reel for damage. Turn by hand to check

for smooth operation. Check for completeness.

2. Configure reel for top, side, or bottom-wind hose dispensing

by removing bolts (or nuts) (1) securing guide arm bracket

(2). Caution: When changing guide arm positions, the

U-bolt must be placed in the proper location as instructed

in figure A below. The reel can “latch out” during use if this

instruction is not adhered to.

3. Determine new guide arm bracket location and remove cor-

responding bolts, (or nuts). Position guide arm bracket to

reel and replace bolts (or nuts).

4. Position reel on floor, wall or ceiling. Secure into place

using four (customer supplied) screws or bolts (3).

INSTALLING THE INPUT HOSES

Caution: Apply teflon tape to all input connections to insure

a proper seal.

INSTALLING THE OUTPUT HOSES

Caution: Use extreme caution; reel under tension, avoid

releasing latch mechanism. Apply teflon tape to outlet connec-

tions.

1. Manually turn spool assembly until spring is tight, back off

three turns, then latch.

2. Route output hoses through guide bracket.

3. Using a wrench, firmly hold on to output fittings on swivel

while tightening the hose connector.

1

2

3

Acetylene/fuel gas

inlet 1/4” FPT

(Red)

Oxygen

inlet 1/4” FPT

(Green)

Acetylene/fuel gas

inlet 1/4” FPT

Series TW

Series SW