RCL40 & RCL41

Installation manual

Regasense is a part of Regal Components |

Rev. no.

2021_1

2

Introduction

Intended use Used symbols

General attention

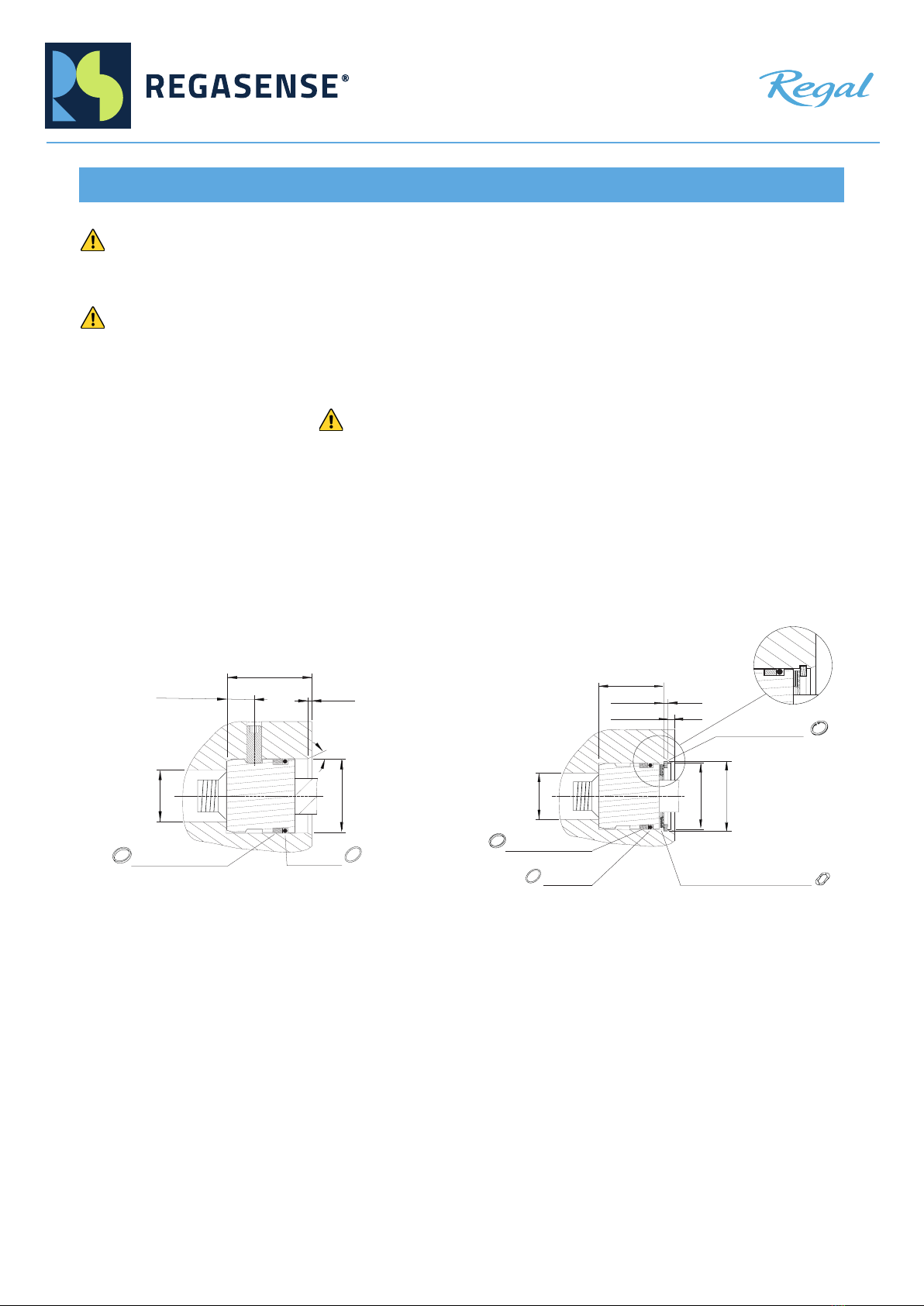

Regasense RCL40/41 sensors are designed to be

installed in hydraulic cylinders with the purpose of

absolute linear positioning.

This manual shall be read together with the data-

sheet.

Safety instructions

Installation and commissioning shall be performed

by technical personnel with appropriate training

and expertise. Whom are trained in the field of

applicable automation technology and installation,

commissioning and/or service operations of the

hydraulic cylinder in use.

If sensor failure or malfunction can cause injury to

person or damage to property, design the system

with additional safety measures to prevent injury or

damage.

Warranty

Regal Components AB grants warranty according to Nordiska leveransbestämmelser (NL09) in applicable

areas or Orgalime S2012. Warranty is not provided for defects due to improper use, storage or excessive

stress on the product.

Warranty is not provided if the product has been modified. No repairs are allowed, in event of sensor mal-

function contact Regal Components AB.

Storage instructions

The sensor must be stored in a dry environment

within the temperature range specified in the da-

tasheet. The sensor shall not be under mechanical

stress that can cause damage to the sensor rod.

Correct storage prior too installation is necessary to

ensure proper function.

Regal Components ABRegal Components AB

Lefflersgatan 1Lefflersgatan 1

SE - 754 50 UppsalaSE - 754 50 Uppsala

SWEDENSWEDEN

+46 (0)18 65 70 00+46 (0)18 65 70 00

www.regal.sewww.regal.se