5 │

REGULUS - Electric Heating Element - www.regulus.eu

2.5.1 - DHW heating in a hot water storage tank

In order to heat water in the hot water storage tank, open the cold water inlet valve, ll the tank with water and

airbleed it by opening the hot water tap. Set the thermostat knob to the desired temperature. The two green

lights on the heating element will light up. When the water is heated to the desired temperature, the green light

marked will go out. The green lights will be on to indicate that the heater is connected to the mains and

is switched on. If the green light marked is not lit, the heating element is switched off by the adjustable

thermostat.

It is recommended to set the thermostat knob to 60 °C. This temperature guarantees the best operation of the

heating element and at the same time, it offers:

- protection against Legionella

- cost reduction

- slower deposit formation

2.5.2 - Heating uid heating in a heating system thermal store

Fill the heating system with heat-transfer uid, air-bleed it and pressurize to the working pressure. Set the ther-

mostat knob to the desired temperature.

If a temperature above 60 °C is to be set, the limiting spring under the knob shall be removed.

Steps:

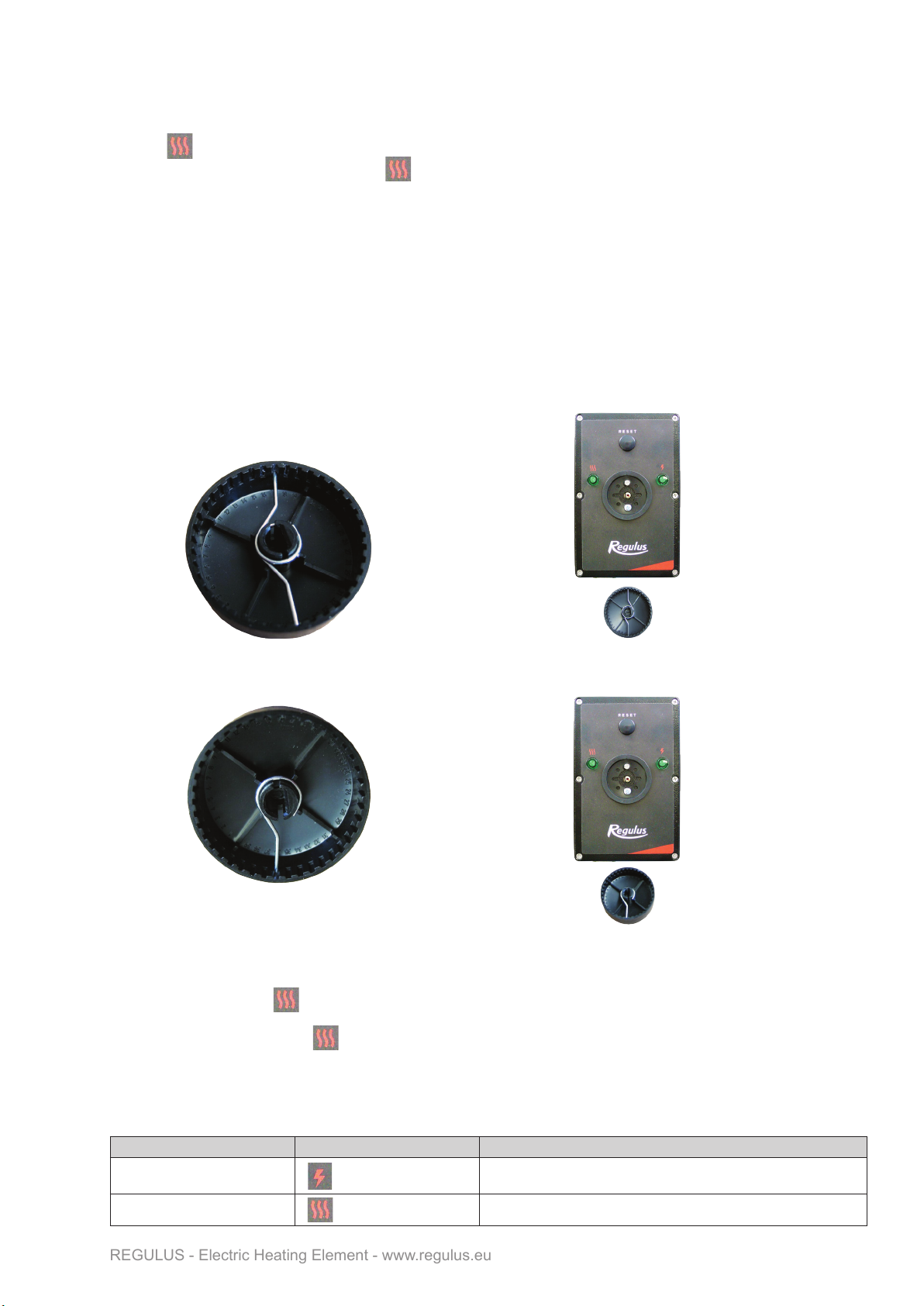

- Pull the knob off the shaft.

- There are two limiting springs inside the knob. Remove the upper spring. It is tted in the groove 17

and limits the adjustable temperature to 60 °C. (Just one spring will remain in the knob, tted in the

groove 37, it limits the min. adjustable temperature to 15 °C.)

- Re-t the knob on the thermostat shaft

This modication will increase the thermostat adjustment range to 15-90 °C.

Colour Indication Description

Green The heating element is in order, connected to the mains and ready

for use

Green Heating element is heating

The two green lights on the heating element will be on. When the water is heated to the desired temperature,

the green light marked will go out. The lit green indicator LEDs indicate that the heating element is con-

nected to the mains and switched on.

If the green LED light marked is not lit, the heating element is switched off by the adjustable thermostat.

2.5.3 - Heating element state during operation

During operation, the status of the heating element is indicated by indicator lights with the following meaning: