1. Introduction

RegulusRGMAT E W6 Load Unit makes boiler installation quicker as it contains all components needed

for boiler circuit circulation and for boiler protection against low-temperature corrosion. It is designed to

be installed directly on a boiler return piping. The distance of pipe axis from a wall shall be at least 100

mm to enable insulation removal if needed. This Load Unit is intended for hydronic fireplaces and

solid-fuel boilers.

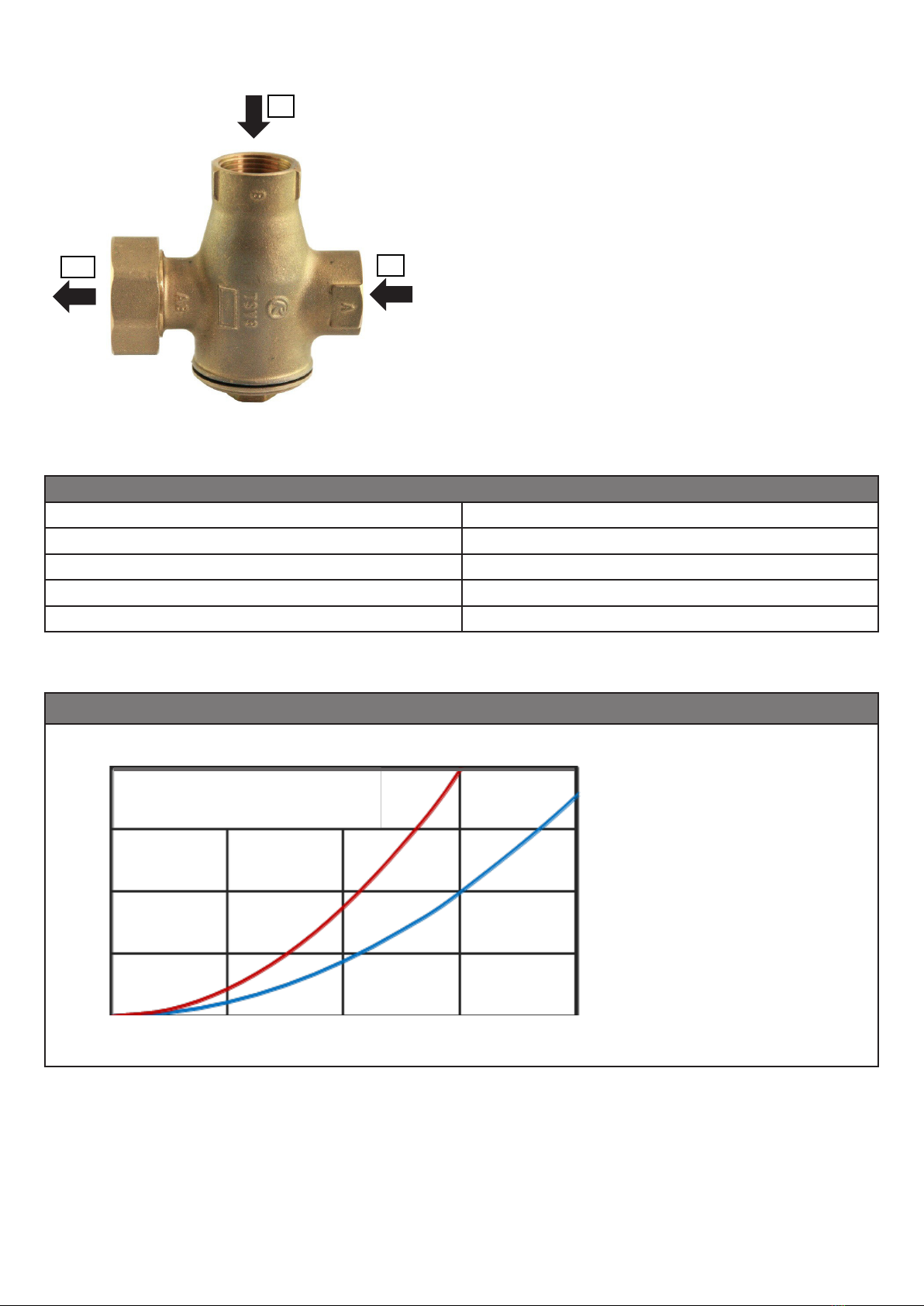

2. Description of the Load Unit

RGMAT E W6 keeps the temperature in a hydraulic boiler circuit above the flue gas condensation

temperatures, which prevents so called low-temperature corrosion of the boiler combustion chamber.

This limits condensation and boiler tarring significantly, the efficiency of fuel combustion increases and

service life of the boiler is extended.

Main Features

Function maintaining a minimum inlet temperature into a boiler (fireplace)

through a load valve

Application Load Unit for solid-fuel boilers and fireplaces; it prevents

low-temperature corrosion and boiler (fire) fouling

Description consists of Wilo PARA SC 25/6 pump, TSV3B valve (with

automatic by-pass balancing), thermometer and insulation

Working fluid water; water/glycol mixture (max. 1:1) or water-glycerine

mixture (max. 2:1)

Installation on return pipe, min. pipe centre distance from wall is 100 mm

Code Max. boiler output

18668 for opening temperature 45 °C 45 kW at ΔT 20 K

18680 for opening temperature 50 °C 42 kW at ΔT 20 K

18612 for opening temperature 55 °C 36 kW at ΔT 20 K

18681 for opening temperature 60 °C 32 kW at ΔT 20 K

18682 for opening temperature 65 °C 25 kW at ΔT 20 K

18683 for opening temperature 70 °C 22 kW at ΔT 20 K

Data for RGMAT E W6 Load Unit

Fluid working temperature 5 - 95 °C

Max. working pressure 6 bar

Min. working pressure 0.5 bar

Ambient temperature 5 - 40 °C

Max. rel. humidity 80% non condensing

Insulation material EPP RG 60 g/l

Overall dimensions 325 x 140 x 155 mm

Total weight 3.1 kg

Connections 3x G 1" F

Accessories

Bypass with non-return valve code 16126