2.

General

Single Interlock Preaction Systems are designed for water

sensitive areas that require protection from inadvertent water

flow into the sprinkler system piping.

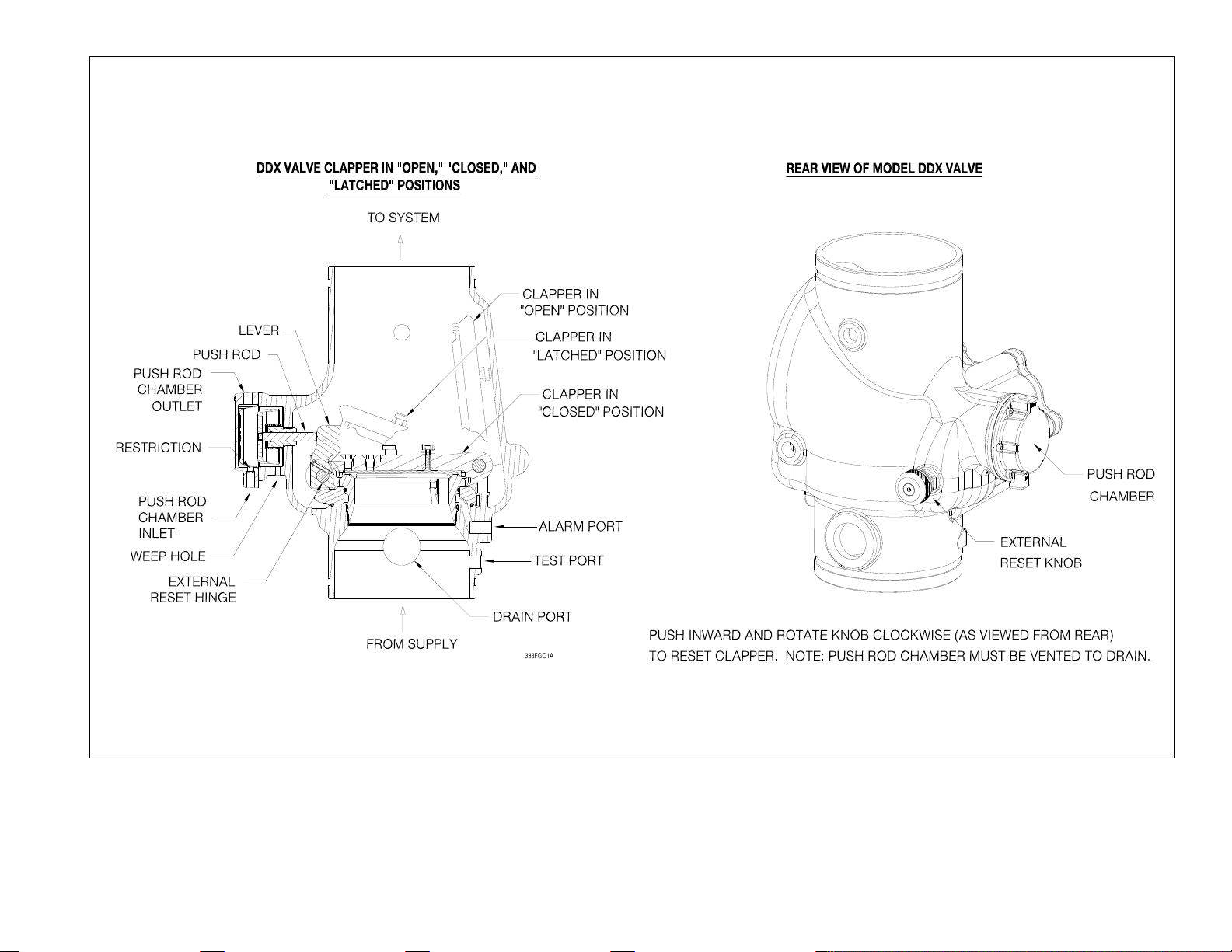

At the heart of the Reliable Single Interlock Preaction System

is the Model DDX Deluge Valve. This deluge valve is a hydrau-

lically operated, straight-through-design, differential latching

clapper-type (see Fig. 1). System maintenance is simplied

since the deluge valve can be reset externally without removing

the cover plate. This feature provides a signicant system-res-

toration time advantage. The Model DDX Deluge Valve has an

intermediate chamber and thereby does not require an in-line

air check valve. Subsequently, the deluge valve only requires a

single drain connection.

The trim sets for the single interlock preaction systems provide

all of the necessary equipment for connections to the Model

DDX Deluge Valve’s pushrod chamber inlet and outlet ports, a

1¼” (30 mm) main drain on 2” (50 mm), 2½” (65 mm), 76 mm

and 3” (80 mm) valve sizes or a 2” (50 mm) main drain on 4”

(100 mm), 165 mm, 6” (150 mm) and 8” (200 mm) valve sizes,

alarm devices, air supply, and required pressure gauges. The

trim sets are available in individual (loose) parts, in time-saving,

segmented assembled kit forms or fully assembled to the Model

DDX Deluge Valve (with or without a control valve). The major

benets of a single interlock preaction system, when compared

with a wet pipe or deluge system are as follows:

• A re alarm sounds prior to the operation of a sprinkler

head, which may enable extinguishing the re by handheld

means before the actual operation of any sprinklers and

subsequent water damage.

• A trouble annunciator signals whenever the integrity of

the piping or sprinklers is accidentally or intentionally dis-

turbed; however, no water flow or water damage will occur

at that time.

• Speedy detection and an early re alarm are provided by

re detectors, without the delay associated with water de-

livery time in the event of a re. Note that with a wet pipe

system, the re alarm is delayed until after water has begun

flowing from an operated sprinkler head.

Sprinkler piping in Wet Pilot and Electric Actuation Single

Interlock Preaction Systems can effectively be supervised by

means of a Reliable Model B-SI Air Compressor Panel or Model

C-SI Air Compressor Panel. Loss of supervisory pneumatic

pressure due to a damaged sprinkler or sprinkler pipe will not

cause water to flow through the Model DDX Deluge Valve and

into the system piping. Loss of pneumatic pressure will activate

a trouble-annunciating device when the system pressure falls

below approximately 4 psi (0.3 bar). Note: Wherever the word

“air” is used in this bulletin as a reference to the pneumatic pres-

sure source it shall also mean “air or nitrogen.”

Wet Pilot Line Single Interlock Preaction Systems use a

pilot line consisting of a line of closed sprinklers or pilot line de-

tectors (Reliable’s Model F1-FTR), which are located in the area

to be protected. These sprinklers/detectors are more sensitive

(lower activation temperature) than the sprinkler heads installed

in the re sprinkler system. The wet pilot line is directly installed

to the Model DDX Deluge Valve pushrod chamber. Wet pilot

line sprinklers are detection devices and do not provide any wa-

ter to aid in the reghting capability of the re sprinkler system.

To fully operate a Wet Pilot Line Single Interlock Preaction

System, heat from a re must fuse a wet pilot line sprinkler/

detector thereby releasing the water pressure from the Deluge

Valve pushrod chamber. As water pressure is lost in this cham-

ber, the main water supply will open the Deluge Valve clapper,

thereby flowing water into the re sprinkler piping. Water flowing

into the system will flow through the intermediate chamber of

the deluge valve to a mechanical sprinkler alarm (if present) will

simultaneously activate the alarm pressure switch mounted in

the trim. The alarm pressure switch can electrically initiate the

shut-down or start up of equipment, such as computer, HVAC,

or other secondary alarm devices. The flow of water into the

sprinkler system piping converts the dry system into a wet sys-

tem. In the event that the re subsequently produces enough

heat to operate a re sprinkler, water will flow from that sprinkler.

The re sprinkler system piping supervised (see NFPA 13)

with air pressure. Loss of supervisory air due to a damaged

sprinkler or the sprinkler piping will not cause the Model DDX

Deluge Valve to open. The supervisory air supply for the re

sprinkler piping may effectively be supervised by the Reliable

Model B-SI Air Compressor Panel or the Reliable Model C-SI

Air Compressor Panel. Other options include the use of the Re-

liable NS-PaK or Nitrogen Regulator with an approved nitrogen

source, the Reliable Model A Pressure Maintenance Device

with a tank-mounted air compressor, or a tank-less air com-

pressor controlled by a pressure switch or the Reliable Model B

Air Maintenance Device. (See Reliable Bulletin 251).

In Electric Actuation Single Interlock Preaction Sys-

tems, when one electrical detector senses the presence of

re, the electrical releasing control panel operates the normally-

closed solenoid valve (175 psi (12.1 bar) or 300 psi (20.7 bar)

rated) to the open position. The solenoid valve, when closed,

retains sufcient water pressure in the pushrod chamber of the

Model DDX Deluge Valve to maintain it closed. Energizing the

solenoid valve relieves the water pressure, thus opening the

Deluge Valve and allowing water to flow into the sprinkler sys-

tem. The flow of water into the sprinkler system piping con-

verts the dry system into a wet system. In the event that the re

subsequently produces enough heat to operate a re sprinkler,

water will flow from that sprinkler.

To fully operate a cross-zoned single interlock system, two

electrical detectors must activate and a sprinkler must open.

During the early stages of a re, smoke or heat activates the

rst detector, which causes the control panel to produce a local

alarm and an alarm at the main re alarm panel. Electrical relays

inside the releasing control panel can be used to shut down air

moving equipment or activate security doors and other electri-

cal devices when the panel goes into the rst alarm condition.

Subsequent activation of a second, nearby or adjacent, detec-

tor will cause the panel to energize the solenoid valve open and

release water into the sprinkler system piping. Water flowing

into the sprinkler system piping will simultaneously activate the

alarm pressure switch on the valve trim. This pressure switch

can electrically initiate the shut down or startup of equipment,

such as computers or other second alarm devices. The flow of

water into the sprinkler system piping effectively converts the

dry system into a wet pipe system. In the event that the re sub-

sequently produces sufcient heat to operate a sprinkler.