The Reliable Model B-SI/C-SI Air Compressor Panel shall pe-

riodically be given a thorough inspection and test. NFPA 25,

“Inspection, Testing, and Maintenance of Water Based Fire

Protection Systems,” provides minimum maintenance require-

ments. System components shall be tested, operated, cleaned

and inspected at least annually and parts replaced as required.

Listings and Approvals

Underwriters Laboratories, Inc. and UL Canada (cULus)

Listing Category: Air Pressure Maintenance Devices, Automatic

Guide Number: VIOT

FM Approved

Guarantee

For Reliable Automatic Sprinkler Co., Inc. guarantee, terms, and

conditions, visit www.reliablesprinkler.com.

Ordering Information

Specify:

• Model B-SI Air Compressor Panel (P/N 6702010003)

(120 VAC)

• Model C-SI Air Compressor Panel (P/N 6702020003)

(220 VAC)

Application

The Reliable Model B-SI and C-SI Air Compressor Panels are

designed and listed for use in installations governed by NFPA

13 to provide and supervise the air pressure required for single

interlock preaction systems. A 200 gallon system can be filled

in approximately 30 minutes. A bypass is provided for quickly

filling larger systems.

The Model B-SI and C-SI Air Compressor Panels should not be

used with dry pilot single interlock preaction systems. These

systems require substantially more air pressure than wet pilot or

electrically actuated systems. Refer to manufacturers informa-

tion for appropriate air supply for dry pilot actuated systems.

Installation

Location must be coordinated with, and installation made in ac-

cordance with, the requirements of NFPA 13 or NFPA 13R, and all

authorities having jurisdiction.

Check valve included with hose kit must be installed in the hori-

zontal position.

All electrical work must be performed in accordance with appli-

cable local and national codes.

Maintenance

The owner is responsible for maintaining all parts of the fire pro-

tection system in proper operating condition. Any system main-

tenance or testing that involves placing a system component

out of service may eliminate the fire protection that is provided

by the fire protection system.

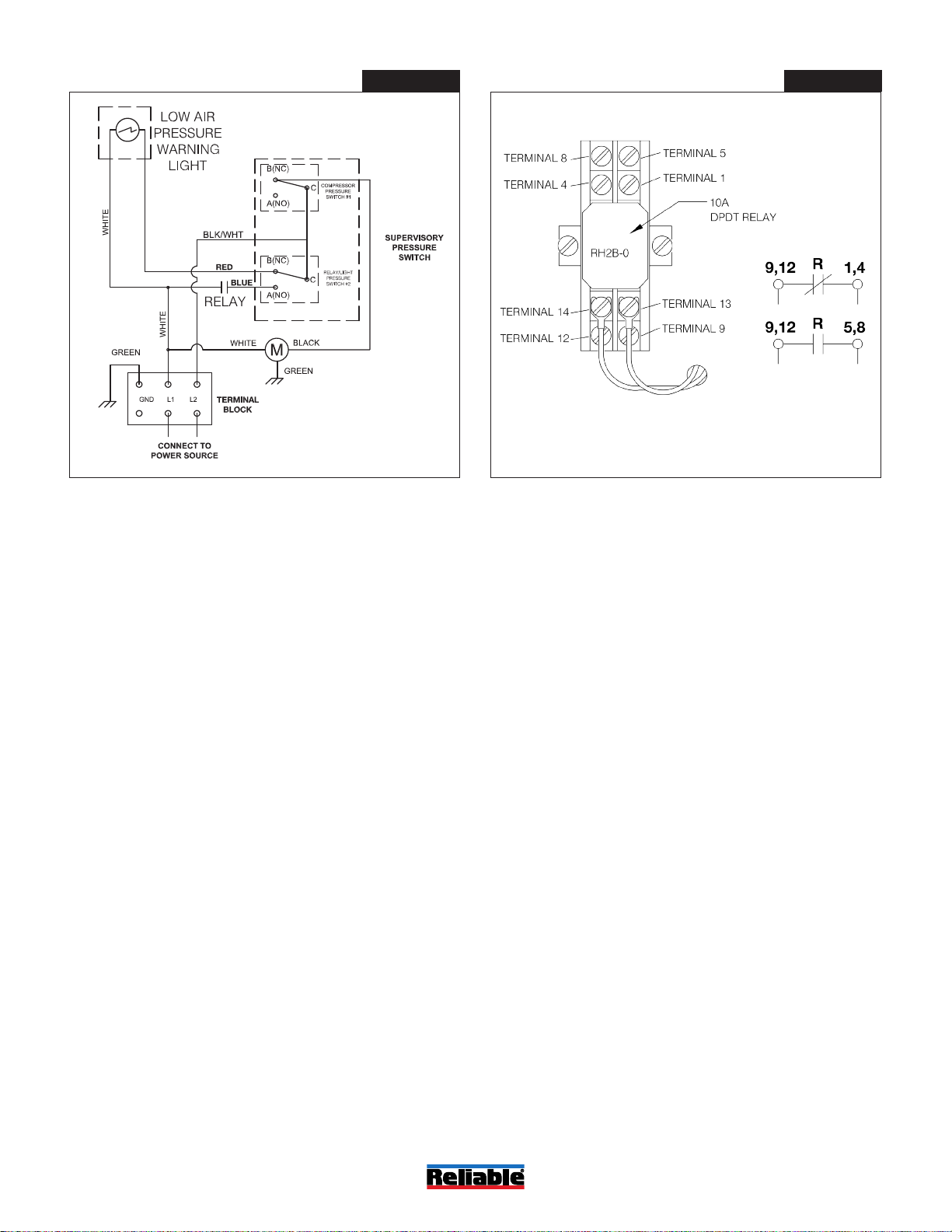

Note: Relay contacts shown in alarm/loss of power condition for

remote monitoring.

Bulletin 252

May 2019

Page 3 of 3

www.reliablesprinkler.com

Figure 3Figure 2

P/N 9999970120

Wiring Diagram Relay Diagram